Light sealing curtain used for thermal treatment furnace

A heat treatment furnace and sealing curtain technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of increased maintenance costs, shortened service life of sealing curtains, detachment of round steel rings, etc. Good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

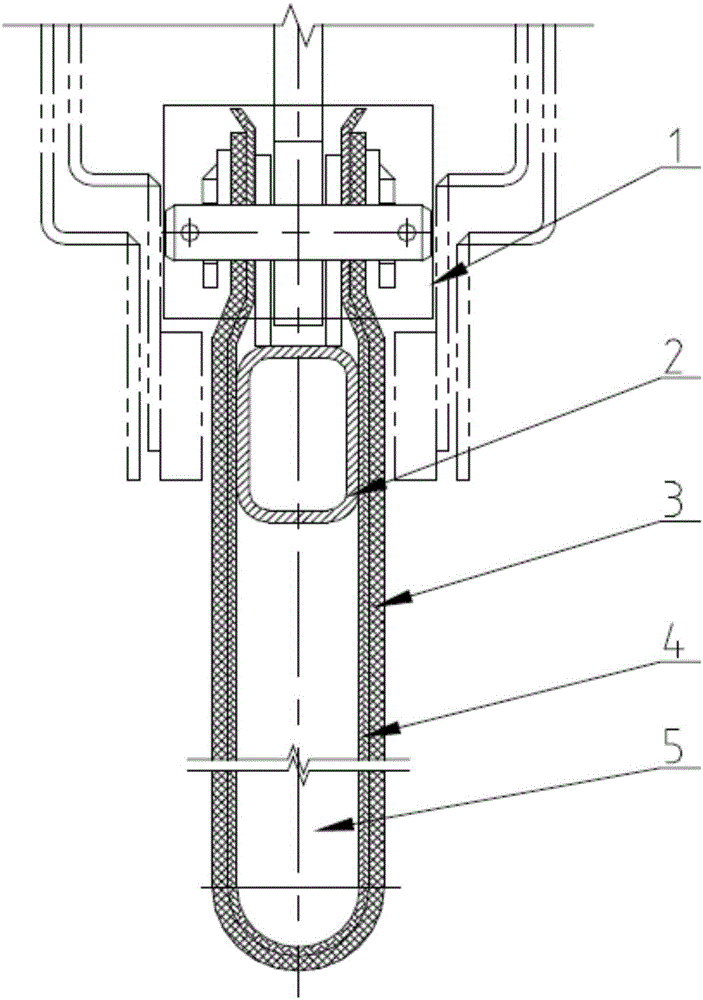

[0014] Heat treatment furnace of the present invention is used lightweight sealing curtain, and its preferred embodiment is:

[0015] It includes stainless steel braided mesh and reinforced heat-resistant steel fiber cloth that are pressed together, and the stainless steel braided mesh and reinforced heat-resistant steel fiber cloth are folded toward one side of the stainless steel braided mesh and hung on the airtight curtain hanging device .

[0016] After the stainless steel woven mesh and the reinforced heat-resistant steel fiber cloth are folded in half, the interior is filled with a heat-insulating fiber blanket.

[0017] A rectangular hollow section steel is provided below the airtight curtain hanging device, and the stainless steel braided mesh and reinforced heat-resistant steel fiber cloth are folded in half to clamp the rectangular hollow section steel.

[0018] The thickness of the reinforced heat-resistant steel fiber cloth is 3mm, the stainless steel braided mes...

specific Embodiment

[0022] Such as figure 1 As shown, the stainless steel woven mesh and fiber silk cloth are folded in half according to the required size, and fixed with rectangular hollow steel under the hanging device. And the hanging device is identical in principle with the existing airtight curtain hanging device.

[0023] Features and advantages of the present invention are:

[0024] 1. Greatly reduce the weight of the existing sealing curtain, which is only 1 / 3 of the weight of the existing sealing curtain.

[0025] 2. The flexibility far exceeds that of the existing sealing curtain, which reduces the scratches on the heat-treated steel plate.

[0026] 3. The sealing and heat preservation performance is higher than that of the existing sealing curtain.

[0027] 3. Simple structure, convenient installation, operation and maintenance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com