Method of preparing sodium dichromate

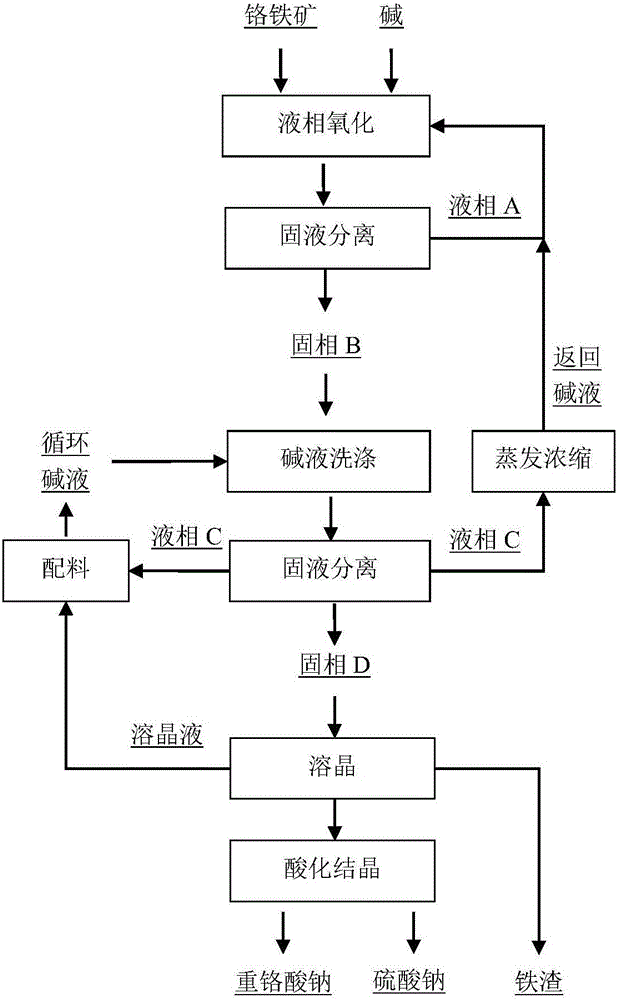

A sodium dichromate and sodium hydroxide technology, which is applied in the preparation of chromate/dichromate, sulfate/bisulfate, etc., can solve the problems of high energy consumption, difficult treatment of chromium-containing slag, and high production cost , to achieve the effects of low energy consumption, avoiding the discharge of chromium-containing water, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Chromite and sodium hydroxide solution are subjected to liquid-phase oxidation reaction, and the slurry is separated from solid and liquid after the reaction to obtain liquid phase A and solid phase B. Liquid phase A contains 60wt% sodium hydroxide and 8wt% sodium chromate, which is used for returning In the liquid phase oxidation reaction of chromite. The solid phase B is washed with circulating lye, the liquid-solid ratio of washing is 1.0, the washing temperature is 120°C, and the holding time is 1h. After washing, the slurry is separated into solid and liquid to obtain liquid phase C and solid phase D, and the concentration of sodium hydroxide in liquid phase C is about 42 wt%. Part of the liquid phase C is evaporated and concentrated to a sodium hydroxide concentration of 50 wt%, and used as a returned lye for liquid-phase oxidation reaction. The solid phase D uses water-dissolved crystals to obtain crystal-dissolving liquid and iron slag. An appropriate amount of...

Embodiment 2

[0047] The chromite is subjected to a liquid-phase oxidation reaction with the mixed solution of the returned lye and the liquid phase A, and the slurry is separated from the solid and liquid after the reaction to obtain the liquid phase A and the solid phase B. The liquid phase A contains 75 wt% of sodium hydroxide, chromic acid Sodium 5wt%, returned for chromite liquid phase oxidation reaction. The solid phase B is washed with circulating lye, the liquid-solid ratio of washing is 0.5, the washing temperature is 70°C, and the holding time is 3h. After washing, the slurry was separated into solid and liquid to obtain liquid phase C and solid phase D, and the concentration of sodium hydroxide in liquid phase C was about 51 wt%. Part of the liquid phase C is evaporated and concentrated until the concentration of sodium hydroxide is 70wt%, and used as the return lye for liquid phase oxidation reaction. Solid phase D uses water-dissolved crystals to obtain crystal-dissolving liqu...

Embodiment 3

[0049] The chromite is subjected to a liquid-phase oxidation reaction with the mixed solution of the returned lye and the liquid phase A, and the slurry is separated from the solid and liquid after the reaction to obtain the liquid phase A and the solid phase B. The liquid phase A contains 70 wt% of sodium hydroxide, chromic acid Sodium 7wt%, returned for chromite liquid phase oxidation reaction. The solid phase B is washed with circulating lye, the liquid-solid ratio of the washing is 1.5, the washing temperature is 50°C, and the holding time is 5h. After washing, the slurry is separated into solid and liquid to obtain liquid phase C and solid phase D, and the concentration of sodium hydroxide in liquid phase C is about 45 wt%. Part of the liquid phase C was evaporated and concentrated to a sodium hydroxide concentration of 62 wt%, and used as a returned lye for liquid-phase oxidation. The solid phase D adopts water-dissolving crystal to obtain crystal-dissolving liquid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com