A PVC ultra-permeable film calendering and winding device

A technology of film roll and swing device, which is applied in the direction of thin material processing, winding strip, transportation and packaging, etc. It can solve the problems of unguaranteed quality, poor film transparency, and air bubbles, so as to reduce the detachment time and air pressure loss , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

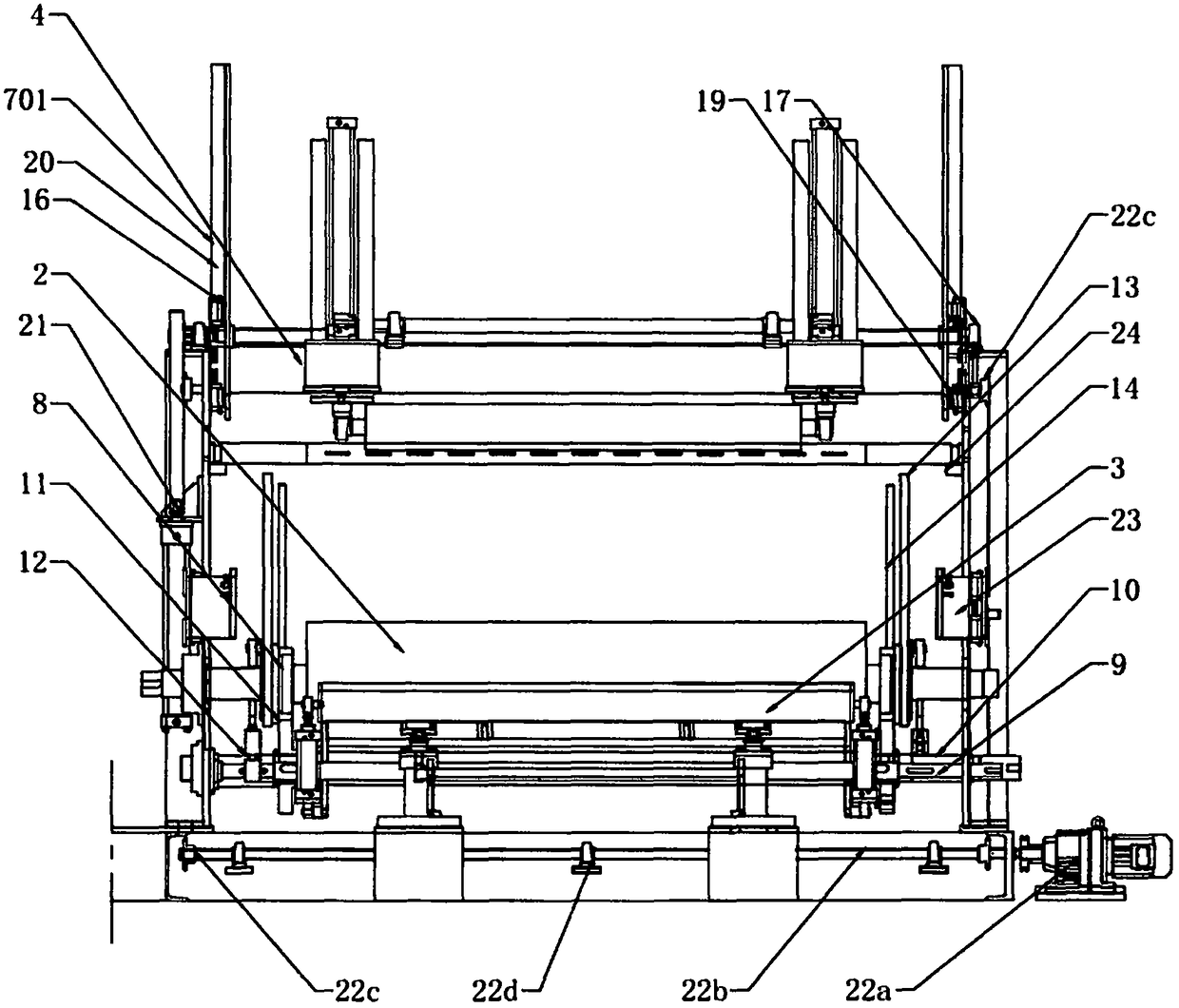

[0021] As shown in the accompanying drawings, the present invention discloses a PVC ultra-transparent film winding device, which includes a frame 1, rollers 2 connected to both ends of the frame 1, lifting platforms 3 symmetrically arranged on both sides of the roller 2, and The beam 4 above the roller 2 is provided with a pressure roller 6 above the roller 2, and the pressure roller 6 moves up and down through the driving device 7 connected to the beam 4, and the two ends of the roller 2 are symmetrical There are two bearing seats 8, and the two bearing seats 8 are respectively sleeved with a synchronous shaft one 9 and a synchronous shaft two 10. The ends of the two bearing seats 8 away from the roller 2 are symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com