A micro-printer movement

A micro-printer and core technology, applied in typewriters, printing devices, printing, etc., can solve the problems of easily damaged micro-printers, difficult disassembly, and printing paper folding, so as to eliminate the difficulty of disassembly, reduce paper jams, and eliminate gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

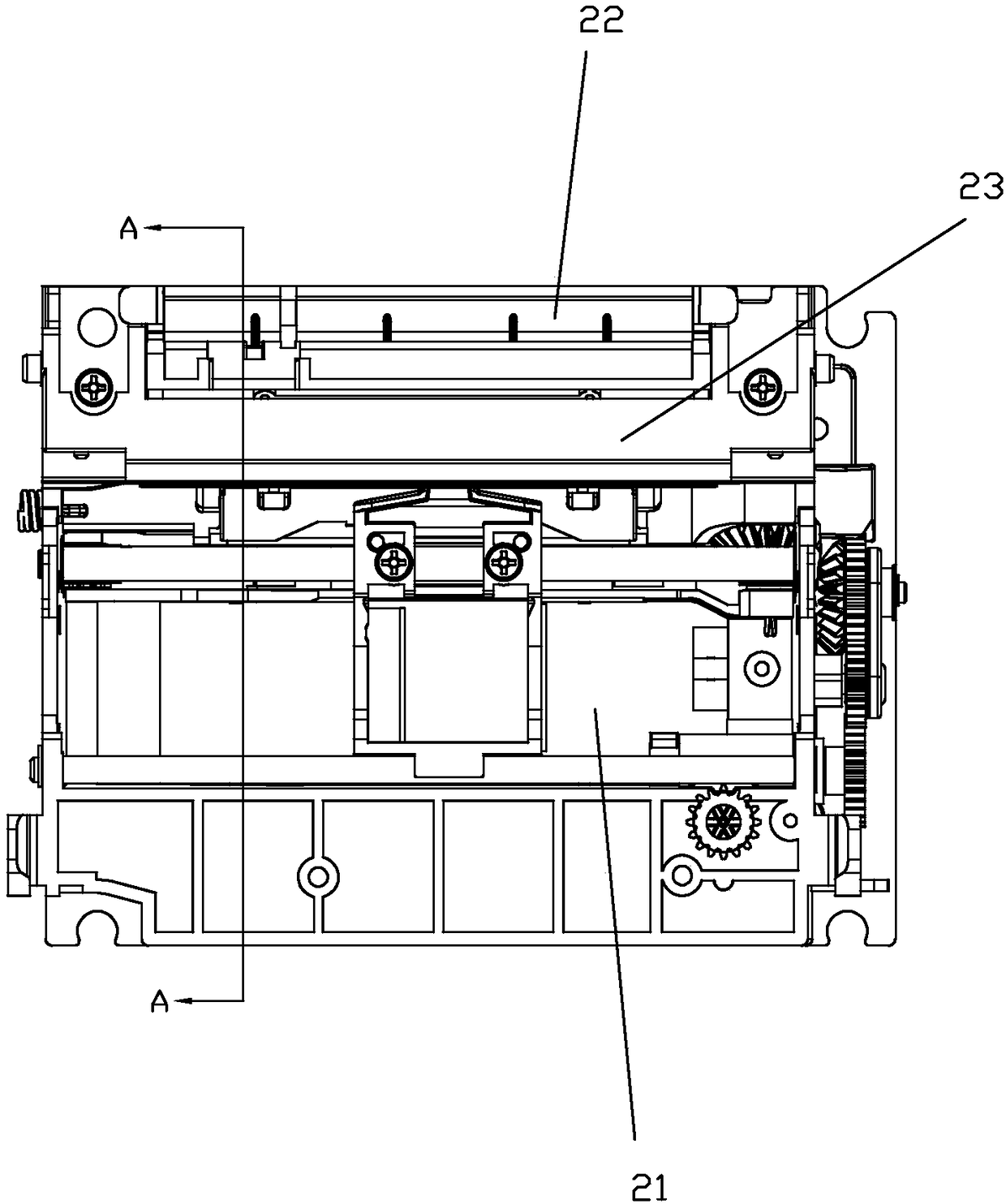

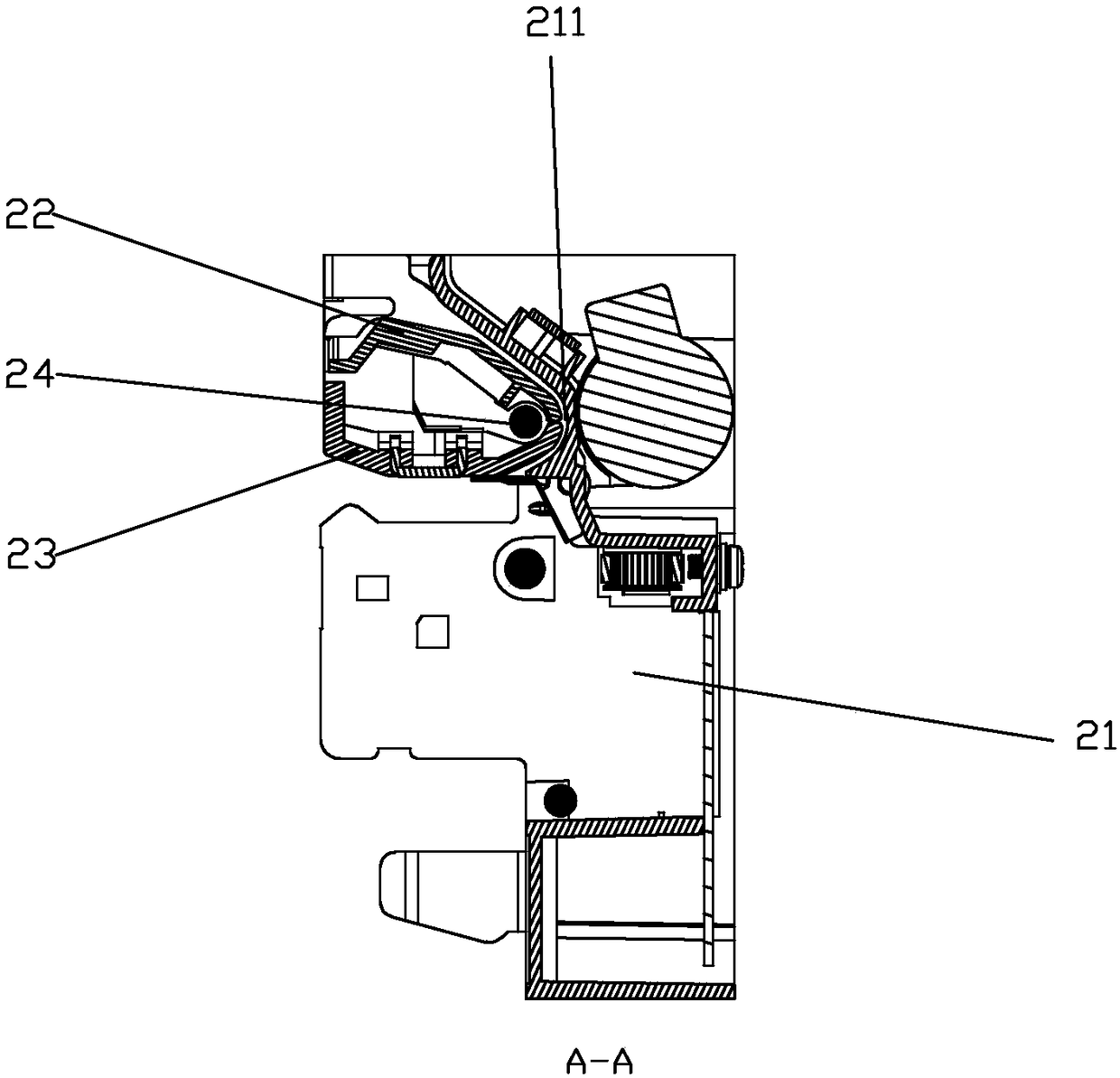

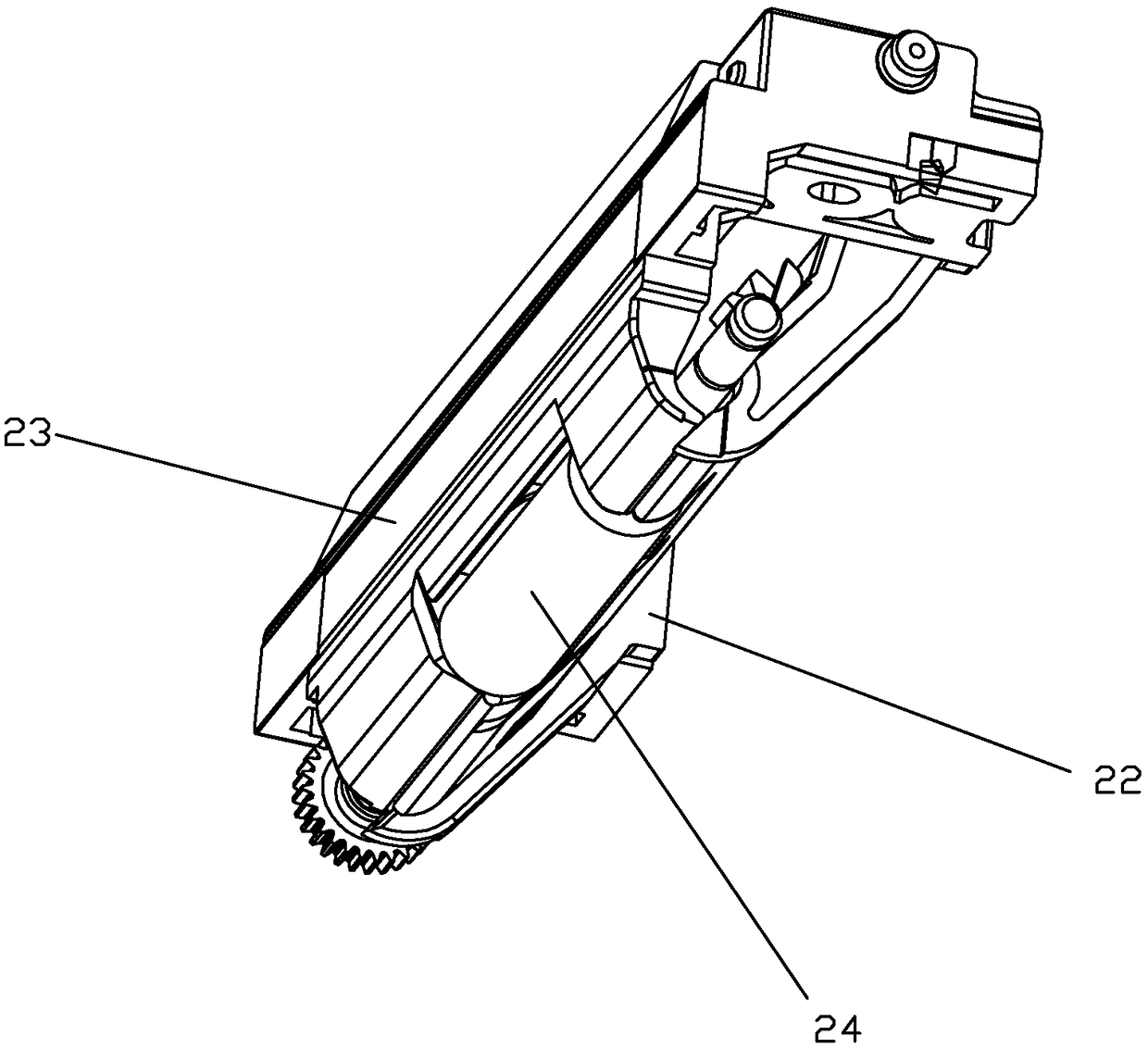

[0028] refer to figure 1 , Figure 4 , Figure 6 , Figure 7 , a micro-printer core, including an injection-molded frame 21, a curved surface groove 211 for passing paper is formed at the rear end of the frame 21, and a color ribbon device for installing a ribbon device is formed at the front end of the frame 21. With supporting frame 212, refer to figure 2 , image 3 , the curved surface groove 211 is connected with an injection-molded upper paper guide plate 22, a printing plate 23, and a paper feed roller 24, and the lower ends of the upper paper guide plate 22 and the printing plate 23 are formed to match the curved surface groove 211. After the upper paper guide plate 22 and the printing plate 23 are assembled, the lower ends of the two are attached together and a paper passage is formed between the curved surface grooves 211 . With the above-mentioned structure, the curved surface groove 211 formed on the frame 21 integrally formed by injection molding is equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com