Laser marking machine

A technology of laser marking machine and laser transmitter, which is applied in the field of marking machines, can solve the problems of insufficiently stable and reliable marking quality, unreasonable and ingenious structure, and high maintenance costs, and achieve stable and reliable marking quality and stable working performance Reliable, the effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

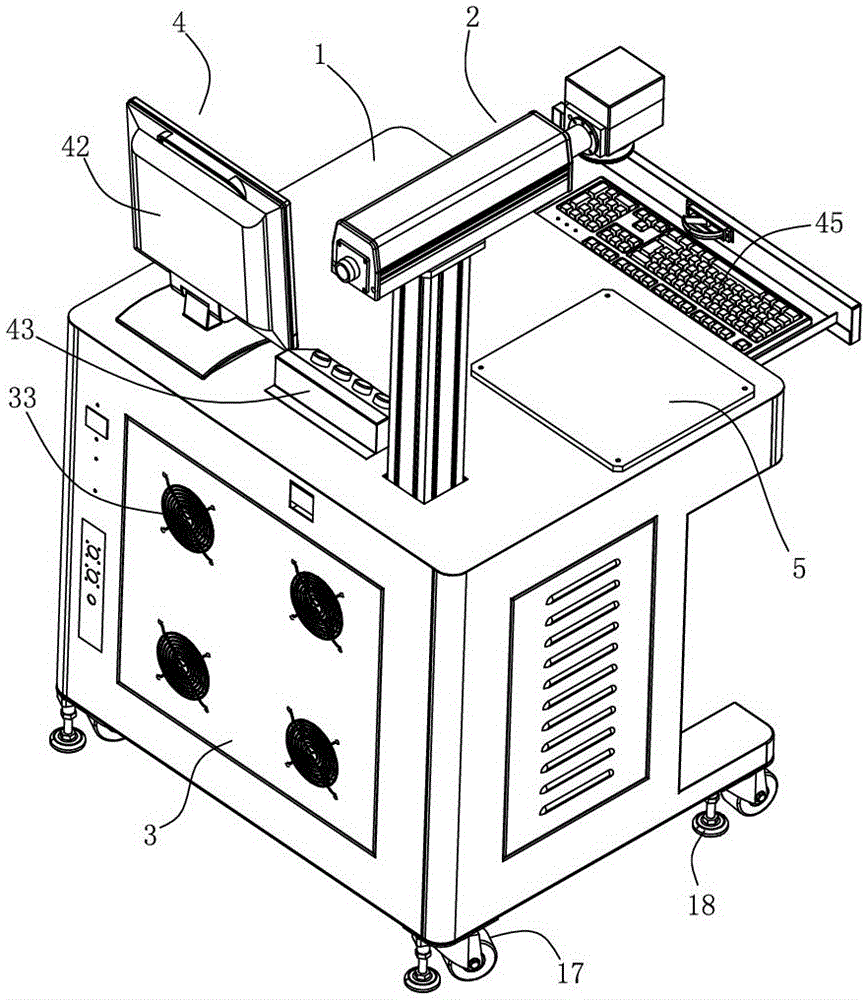

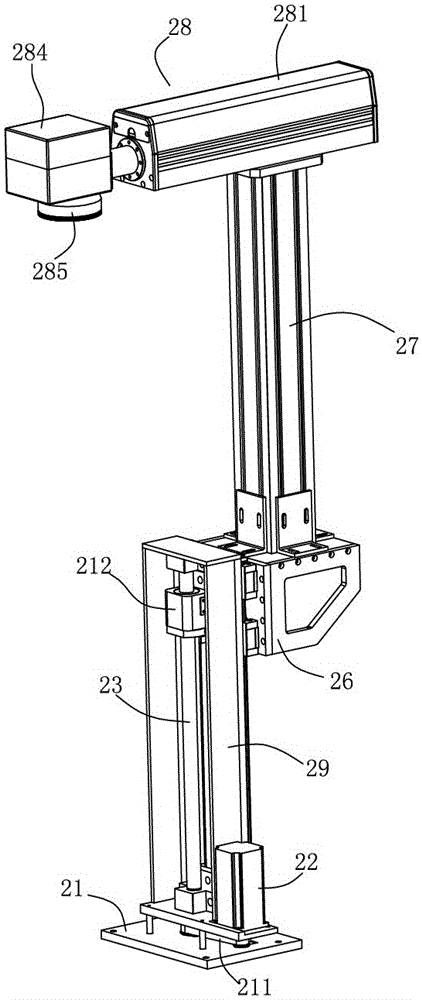

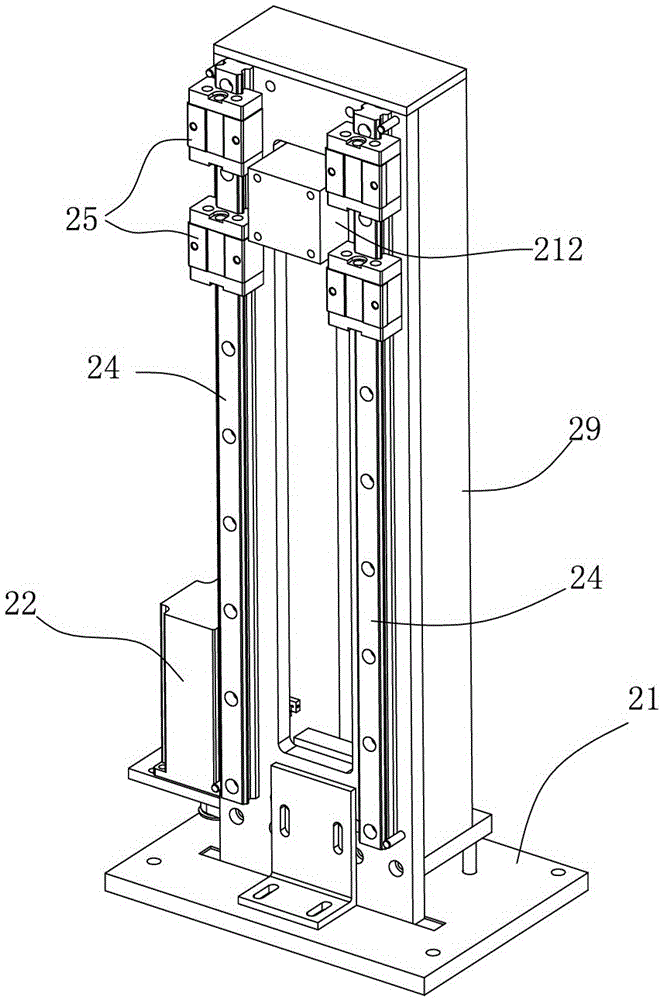

[0030] Example: such as Figure 1 to Figure 7 As shown, a laser marking machine of the present invention includes a machine platform 1, which also includes an auto-focus scanning system 2, a chassis 3 and an industrial control system 4, the chassis 3 is arranged in the machine platform 1, and the industrial control system 4 It is electrically connected with the chassis 3 and the auto-focus scanning system 2. The auto-focus scanning system 2 includes a bottom mounting plate 21, a screw 23 driven to rotate by a motor 22, a guide rail 24 arranged side by side with the screw 23, and arranged on the The slide block 25 that can move up and down on the guide rail 24, the lifting base 26 driven by the screw mandrel 23 that is fixedly connected with the slide block 25 to move up and down, the focus scanning support 27 that is arranged on the lifting base 26, and the setting The focus scanning assembly 28 on the top of the focus scanning bracket 27, the bottom mounting plate 21 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com