Composite leather fabric reducing outward heat escape

A kind of fugitive and leather technology, applied in the field of textile fabrics and fabrics, can solve the problems of uneven product quality, hand feeling, air permeability, and durability, etc., achieve low manufacturing cost, good hand feeling, and ensure torsional bending performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

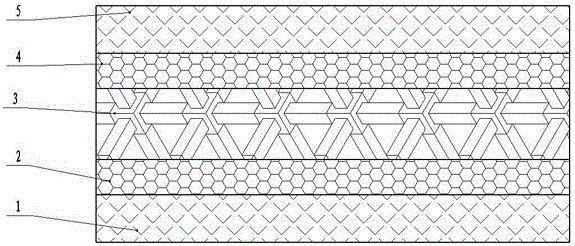

[0025] see figure 1 , a composite leather fabric that reduces heat dissipation outwards, comprising an inner cortex, a first air-permeable layer, a support layer, a second air-permeable layer and an outer cortex, and the first air-permeable layer, the support layer, the second Two air-permeable layers and an outer skin layer, the inner skin layer and the first air-permeable layer are fixed with polyurethane glue, the support layer is fixed with the first air-permeable layer and the second air-permeable layer by sewing, and the second air-permeable layer and the outer skin layer are made of polyurethane Glue it in place.

[0026] The back of the inner skin layer is provided with a lining fabric layer, and the lining fabric layer has at least a temperature-regulating fabric layer and a heat-resistant layer. The difference in moisture regain at 40% is 1% to 8%, and the heat-resistant layer is adjacent to the outer surface of the temperature-regulating fabric layer.

[0027] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com