Self-adaption laser shot blasting shape correcting device based on large data platform and method

A big data platform, laser shot blasting technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of difficulty in obtaining workpiece flatness, different degrees of workpiece, inapplicability, etc., and achieve a good shape correction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

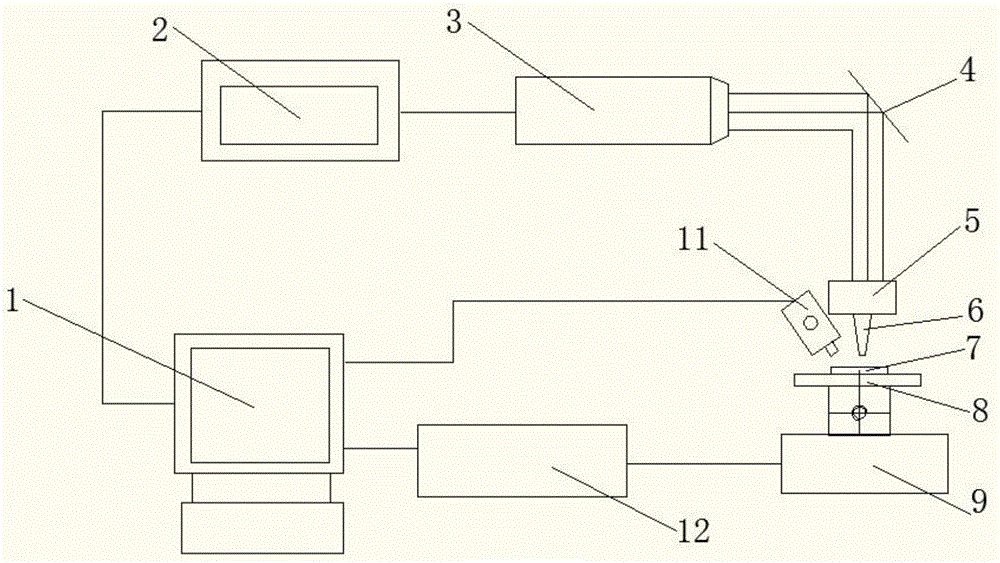

[0012] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

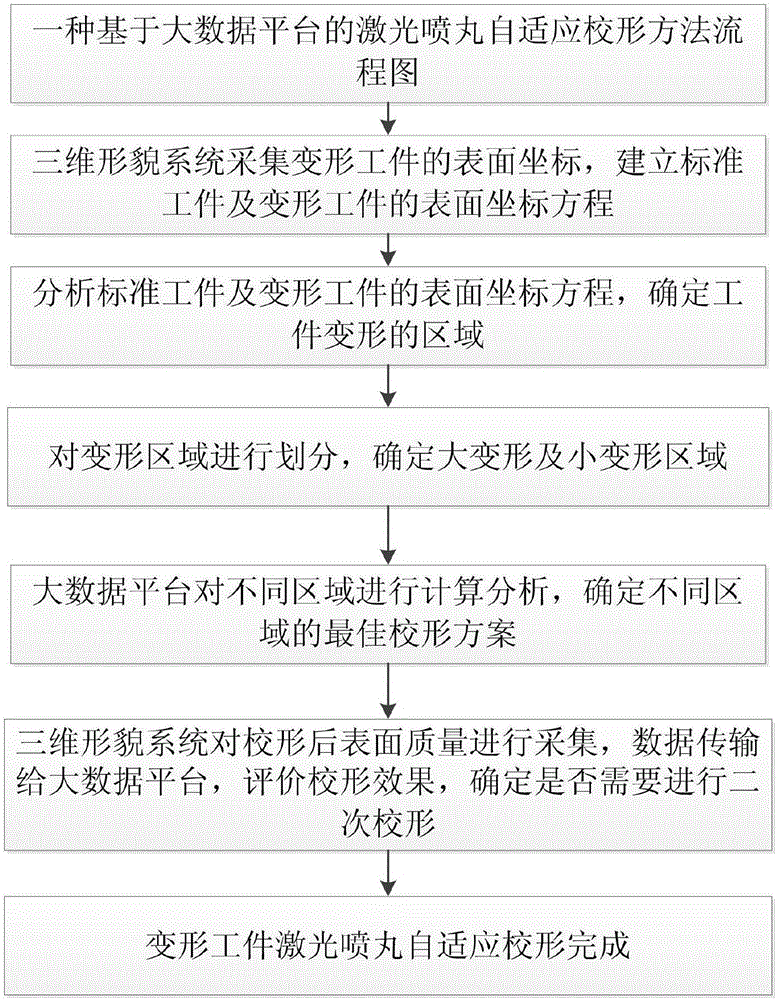

[0013] as attached figure 1 As shown, a laser peening adaptive shape correction device and method based on a big data platform of the present invention is used to correct the shape of an aero-engine bracket.

[0014] After the bracket is welded, heat treatment is carried out, and the weld seam is deformed due to the change of residual stress, so that the bracket cannot be installed and docked with the aero-engine. The method of the present invention specifically includes the following steps:

[0015] (1) Input the three-dimensional shape model of the standard bracket and the deformed bracket, establish the surface curvature equation, and analyze the nodes and areas where the bracket deforms;

[0016] (2) Calculate the best shape correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com