Stamping die for welded electrode cap manufacturing

A technology for welding electrodes and stamping dies, which is used in manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of material waste, dimensional consistency, low production efficiency, etc., to improve material utilization, production efficiency, and density. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

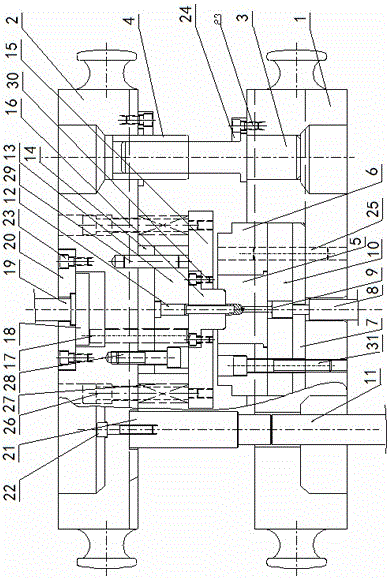

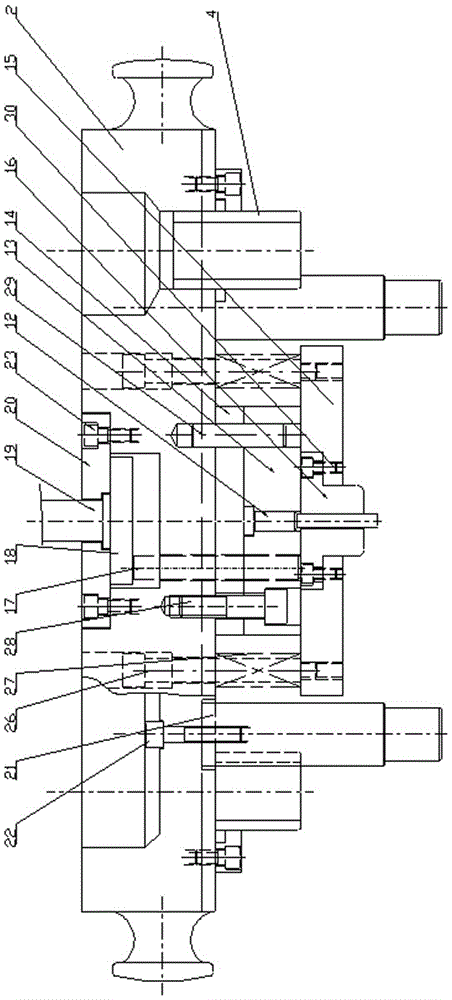

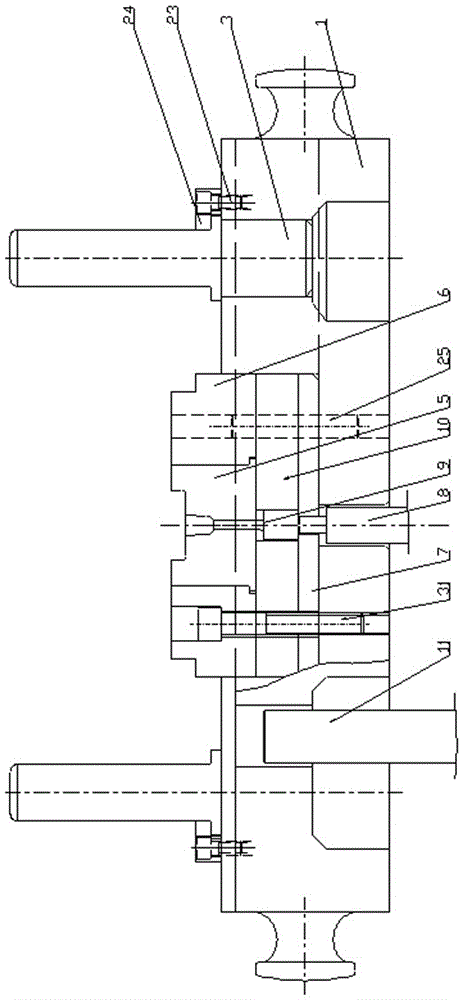

[0015] attached by figure 1 , 2 , 3 shown: the mold includes an upper film body I and a lower mold body II, which is characterized in that: ①, the upper mold body I includes an upper base plate 2, a guide sleeve 4, a punch 12, a punch fixing plate 13, Punch backing plate 14, upper ejector fixing plate 15, upper ejector 16, upper ejector rod 17, upper ejector plate 18, upper ejector rod 19, upper cover plate 20, upper push rod 21, screw 22 , screw 23, stripper plate screw 26, high-strength spring 27, screw 28, column pin 29 and screw 30, wherein the guide sleeve 4 is arranged on the left and right ends of the upper base plate 2, and the upper base plate 2 adopts interference fit pressure In, the upper push rod 21 is set under the left end of the upper base plate 2 through the screw 22, and the upper cover plate 20 is fixed by the screw 23 at the upper middle position of the upper base plate 2. The upper cover plate 20 is provided with a The upper knockout rod 19 that can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com