Cone crusher

A cone crusher and cone technology, applied in the field of ore crushing, can solve the problem of inability to crush ore into small particles, and achieve the effect of high crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

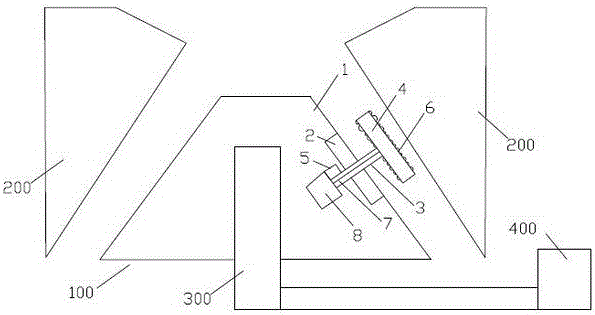

[0023] The cone crusher includes a moving cone 100, a static cone 200 is arranged outside the moving cone 100, and an eccentric bushing 300 is sleeved inside the moving cone 100, and the eccentric bushing 300 communicates with the motor 400 through a transmission device. Connected; the movable cone 100 includes a movable cone main body 1, the outer surface of the movable cone main body 1 is provided with at least one groove 2, and the bottom of the groove 2 is provided with a telescopic grinding rod 3, and the telescopic grinding rod One end of the grinding rod 3 is provided with a grinding pressing plate 4, and the other end of the telescopic grinding rod 3 is connected to the drive motor 5 located inside the moving cone main body 1, and the outer and inner surfaces of the grinding pressing plate 4 are provided with multiple grinding rods for grinding. Abrasive particles of ore6. When the ore falls from the top of the cone crusher to the upper part of the movable cone main bo...

Embodiment 2

[0025] The cone crusher includes a moving cone 100, a static cone 200 is arranged outside the moving cone 100, and an eccentric bushing 300 is sleeved inside the moving cone 100, and the eccentric bushing 300 communicates with the motor 400 through a transmission device. Connected; the movable cone 100 includes a movable cone main body 1, the outer surface of the movable cone main body 1 is provided with at least one groove 2, and the bottom of the groove 2 is provided with a telescopic grinding rod 3, and the telescopic grinding rod One end of the grinding rod 3 is provided with a grinding pressing plate 4, and the other end of the telescopic grinding rod 3 is connected to the drive motor 5 located inside the moving cone main body 1, and the outer and inner surfaces of the grinding pressing plate 4 are provided with multiple grinding rods for grinding. Abrasive particles of ore6.

[0026] The overall longitudinal section of the movable cone body 1 is fan-shaped, and the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com