Lubricated slide rails

A technology of function and slide rail, which is applied in the field of hardware, can solve problems such as unsmooth sliding, violent impact, and serious wear of slide rails, and achieve the effects of avoiding poor sliding or jamming, reducing violent impact, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

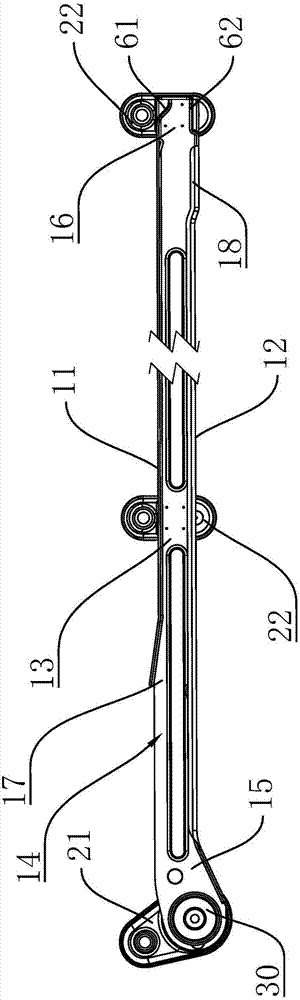

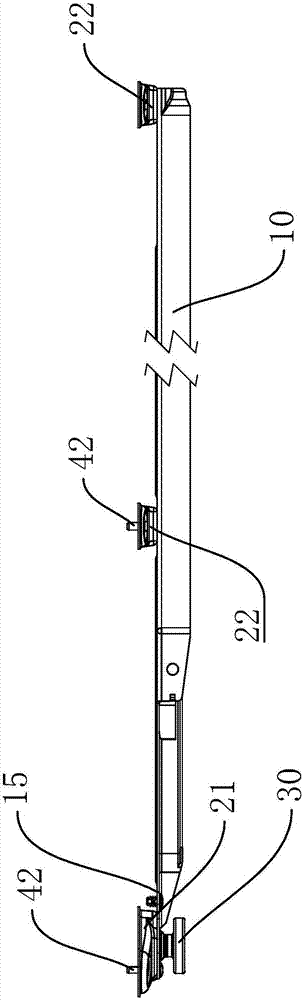

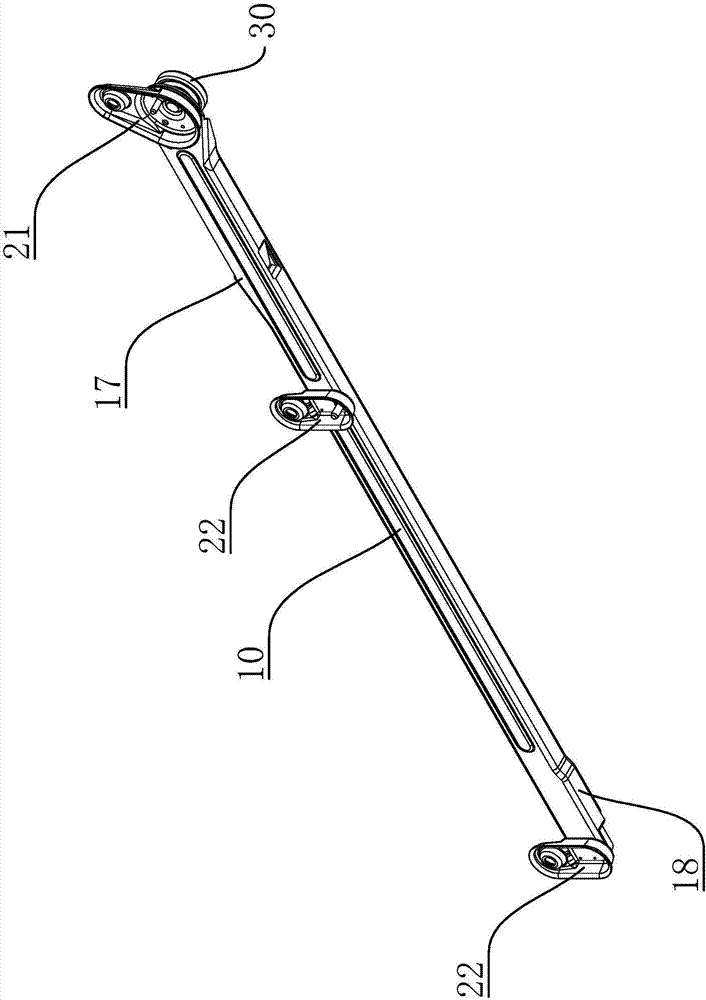

[0033] Such as Figure 1 to Figure 6 As shown, the present invention provides a slide rail with lubricating function, including a slide rail body 10, the slide rail body 10 includes an integrally formed top plate 11, bottom plate 12 and side plate 13, and the top plate 11, bottom plate 12 and side plate 13 are stamped Finally, a chute 14 for sliding guide is formed; the slide rail body 10 has a first end portion 15 and a second end portion 16, and the first end portion 15 is riveted with a fixed portion 21 for slide rail installation, and the second end portion 16 The second fixed part 22 for slide rail installation is welded, at least one fixed part two 22 is also welded between the first end part 15 and the second end pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com