No-tillage cultivation method of dry-land flue-cured tobacco

A cultivation method and dryland technology are applied in the field of commercial crop cultivation, can solve the problems of complicated procedures, high cost, and quality of tobacco fields, and achieve the effects of good application prospect, improvement of chemical and microbial properties, and improvement of production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

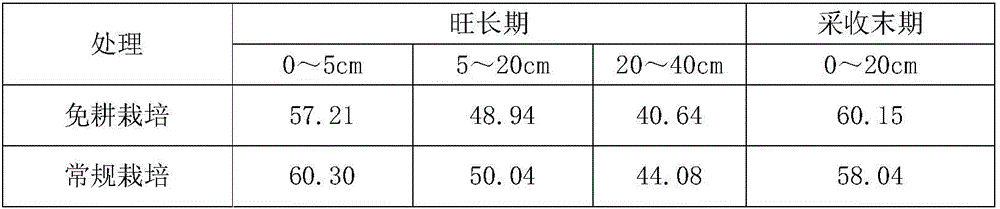

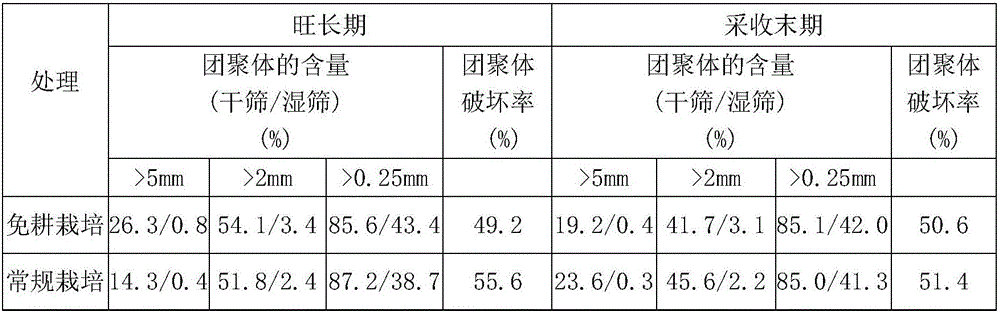

example 1

[0017] Example 1 (community test): In 2013, no-tillage cultivation of flue-cured tobacco on the original ridge was carried out in Fenghuang County, Xiangxi Autonomous Prefecture, Hunan Province. Open a 8-10cm deep and 8-10cm wide ditch in the middle of the ridge body, apply base fertilizer strips in the ditch, and backfill the original soil after fertilization; the amount of fertilizer applied is 50kg / mu of special base fertilizer + 10kg / mu of special topdressing fertilizer + 20kg / mu of active fertilizer , The seedling raising fertilizer is 5kg / mu (special seedling raising fertilizer), and the topdressing is 10kg / mu of special topdressing + potassium sulfate 20kg / mu. The distance between transplanting rows is 1.2m*0.5m. That is, the width of the ridge body is about 40cm, and the horizontal distance between the ridge bodies is about 1.2m. On the same ridge body, only one row of tobacco seedlings is transplanted vertically, and a hole is dug in the middle of the two tobacco plan...

example 2

[0031] Example 2: In 2013, no-tillage cultivation of flue-cured tobacco was carried out on the original ridge in Huayuan County, Xiangxi Autonomous Prefecture, Hunan Province. Open a ditch 8-10cm deep and 8-10cm wide in the center, apply base fertilizer strips in the ditch, and backfill the original soil after fertilization; the amount of fertilizer applied is 50kg / mu of special base fertilizer + 10kg / mu of special topdressing fertilizer + 20kg / mu of active fertilizer, and the seedlings are raised The fertilizer is 5kg / mu (special seedling raising fertilizer), and the topdressing is special topdressing fertilizer 10kg / mu+potassium sulfate 20kg / mu. The distance between transplanting rows is 1.2m*0.5m. That is, the width of the ridge body is about 40cm, and the horizontal distance between the ridge bodies is about 1.2m. On the same ridge body, only one row of tobacco seedlings is transplanted vertically, and a hole is dug in the middle of the two tobacco plants for transplanting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com