A bolt-free double-flange vertical vibration motor

A technology of vibrating motors and double flanges, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of difficult maintenance, low protection level, and low product life, so as to extend the maintenance cycle, reduce the probability of oil leakage, Effect of reducing motor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

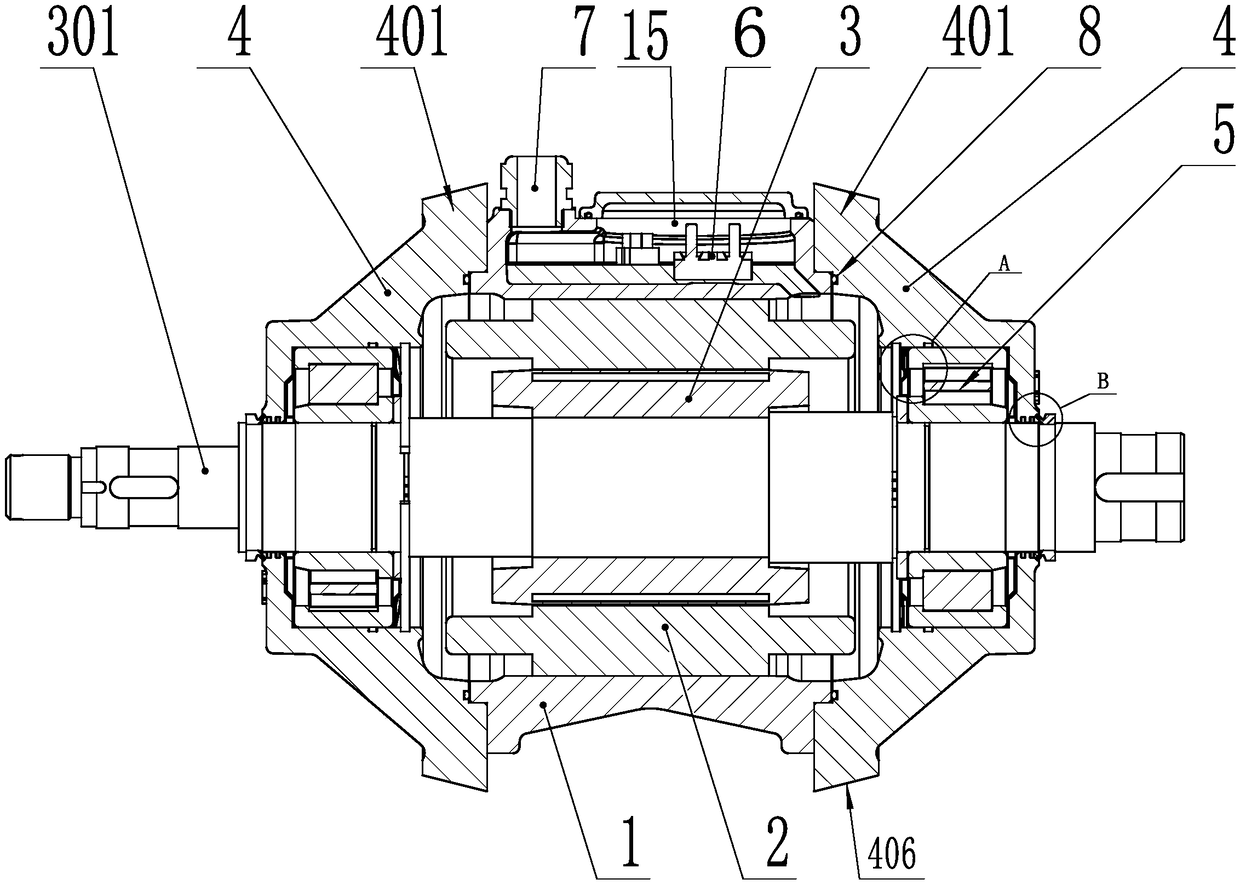

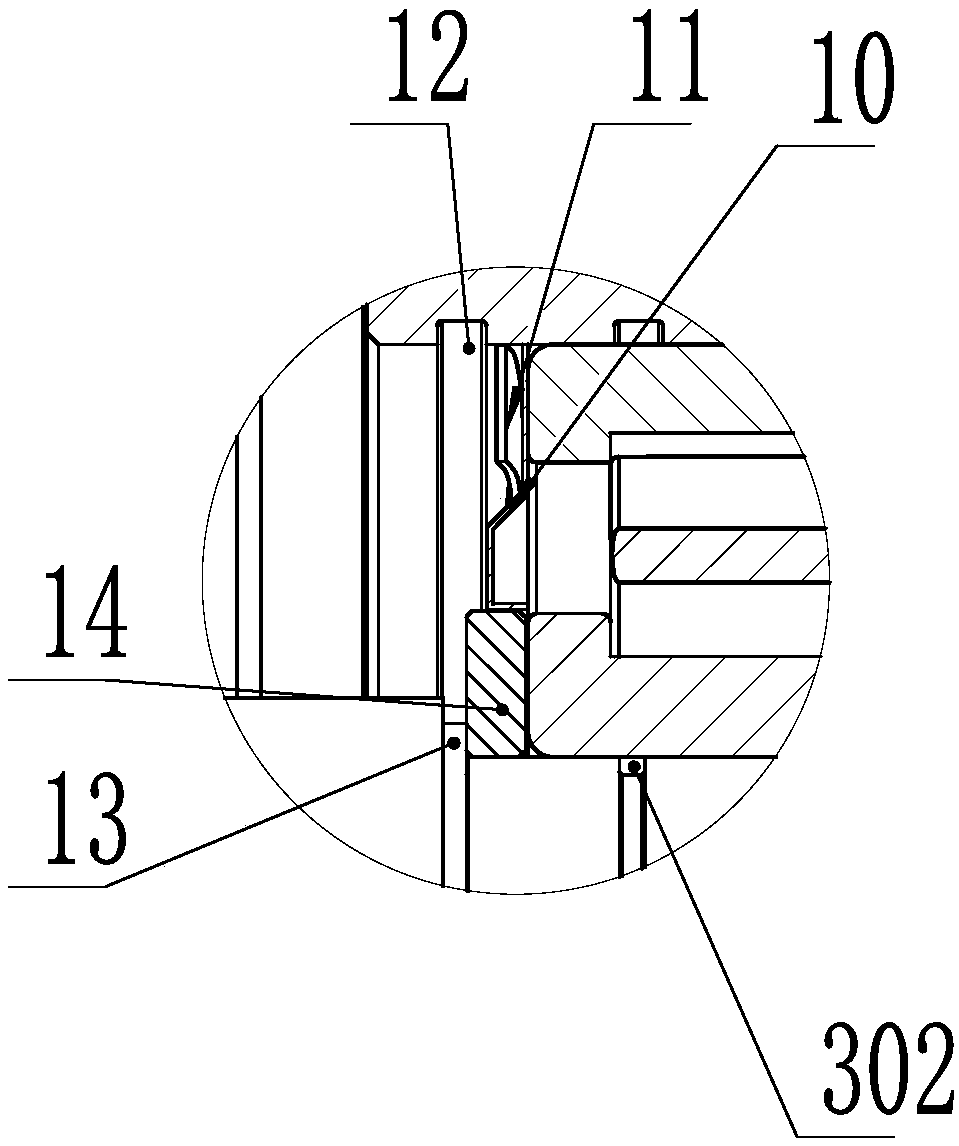

[0025] like Figure 1-4 As shown, it includes the machine base 1, the end cover 4 with bearing chambers inside the machine base 1, the stator 2 set in the machine base 1, the rotor 3 with the rotating shaft 301 matched with the stator 2, and the end cover 4 arranged at the end The bearing 5 in the bearing chamber of the cover 4 and the eccentric block 301 located on the rotating shaft on both sides of the machine base 1, the rotor 3 is connected to the end cover 4 through the bearing 5 that is sleeved on the rotating shaft 301. It is characterized in that: one end of the end cover 4 is connected to the machine The connecting end of the machine base matching the base 1, the connecting end of the machine base protrudes to the outer periphery to form a connecting flange 401 for connecting and fixing with external equipment, the outer pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com