Parallel gap structure of power transmission and distribution line

A technology of transmission and distribution lines and parallel connection, which is applied in the direction of devices maintaining the distance between parallel conductors, etc., can solve problems such as low efficiency, increased use costs, and extended operating time, and achieves quick disassembly and replacement, improved performance, and reduced operating intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

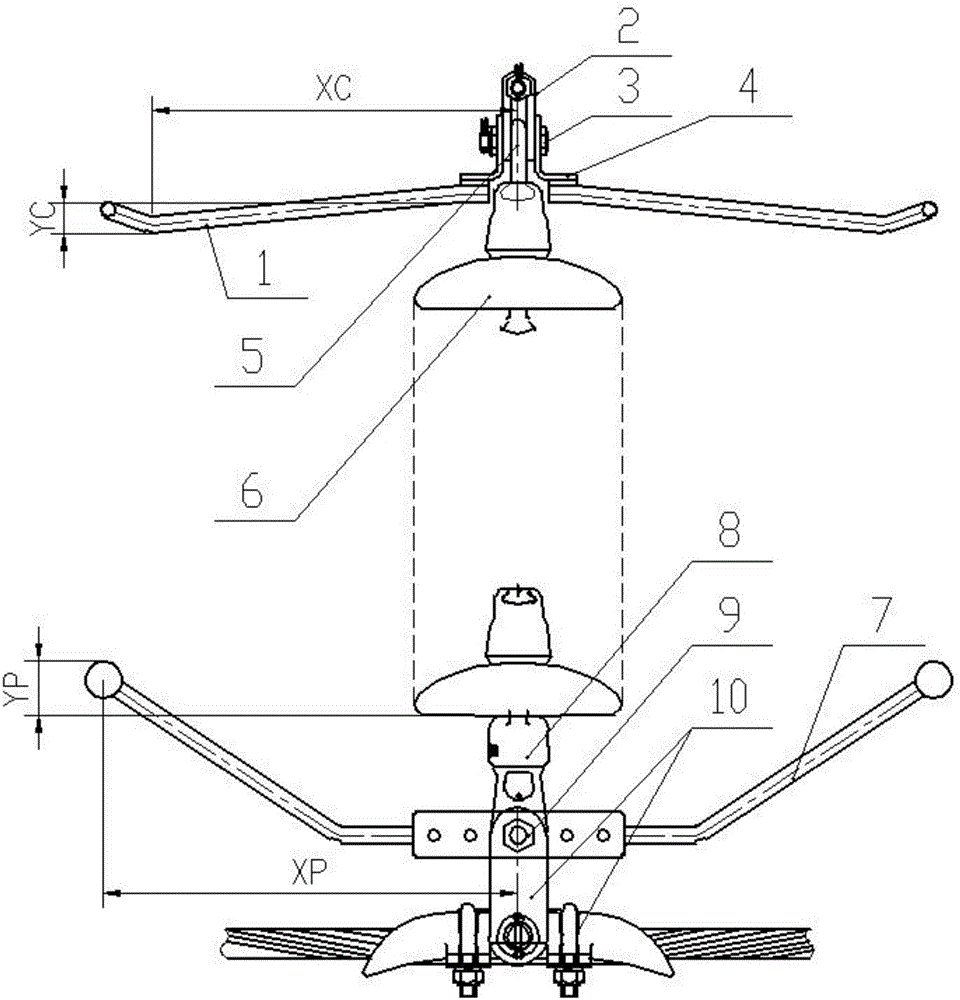

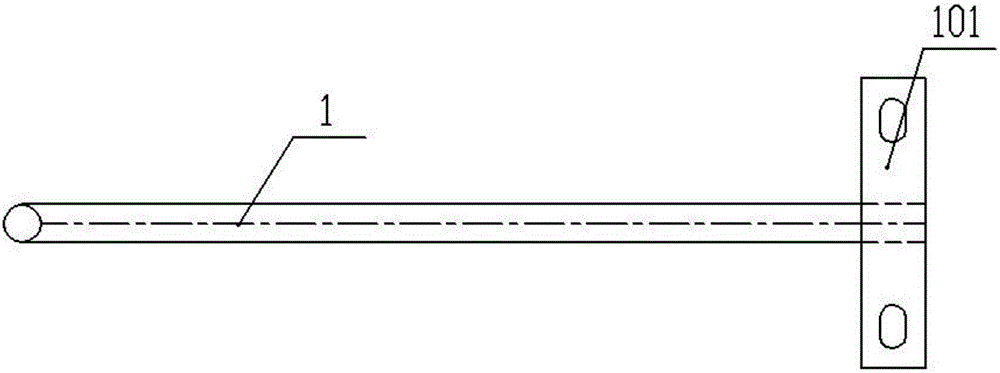

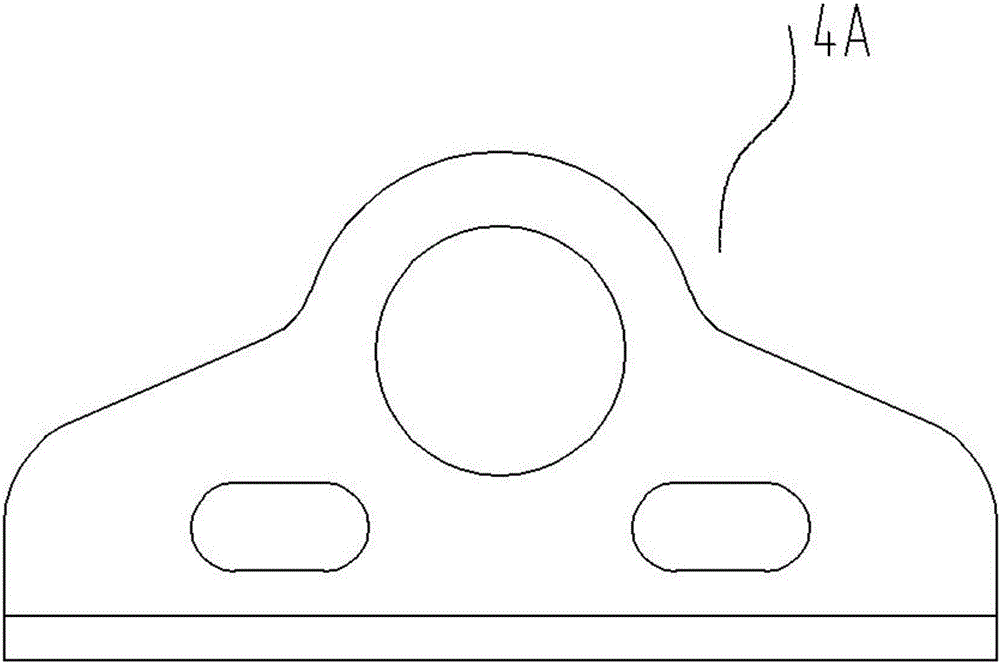

[0025] Such as figure 1 As shown, a structure of a parallel gap for transmission and distribution lines includes an upper arc angle and a lower arc angle, and the upper arc angle and the lower arc angle are respectively connected in parallel at both ends of the insulator string 6 . The upper arc angle includes the symmetrically set left and right halves of the upper arc angle 1, and similarly, the lower arc angle also includes the symmetrically set left and right halves of the lower arc angle 7, and the half upper arc angle The arc angle 1 and the lower arc angle 7 of the half are made of φ18 roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com