Exhaust device for gas relay of transformer

A technology for exhaust devices and relays, applied in switch devices, electrical components, etc., can solve problems such as inability to be operated by operation and maintenance personnel, malfunction of gas relays, electric shock accidents of personnel, etc., to improve work efficiency and operation and maintenance. Timeliness and the effect of avoiding the malfunction of the Buchholz relay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

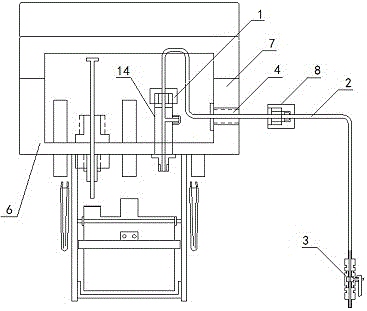

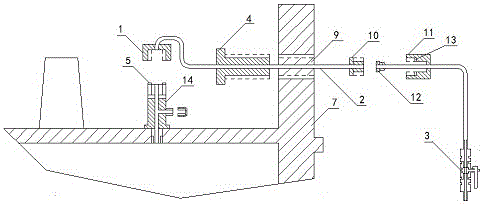

[0011] Below in conjunction with accompanying drawing for further explanation:

[0012] Such as figure 1 , 2 As shown, the present invention is composed of a front end connector 1 , an exhaust pipe 2 , an exhaust valve 3 and a sealing support 4 . The front-end connector is arranged on the front end of the exhaust pipe, and the front-end connector of the present embodiment is a connecting nut whose internal thread matches the external thread of the exhaust nozzle 14 of the gas relay 6 . A sealing ring 5 is arranged between the exhaust nozzle of the gas relay and the connecting nut, and a sealing connection is also between the front end connector and the exhaust pipe.

[0013] The exhaust valve is arranged at the end of the exhaust pipe, and it is sealedly connected with the exhaust pipe.

[0014] The sealing support is sleeved on the exhaust pipe. The sealing support in this embodiment is a bolt sleeved on the exhaust pipe. The external thread of the bolt matches the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com