Solar battery sheet, and solar battery assembly and preparation method thereof

A technology for solar cells and battery sheets, applied in the field of solar cells, can solve the problems of small conductive cross-sectional area and large resistance loss, and achieve the effects of not being limited by space, low cost, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

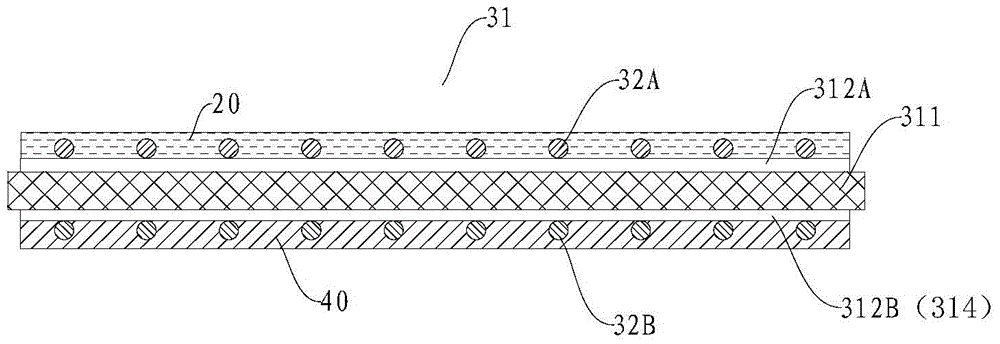

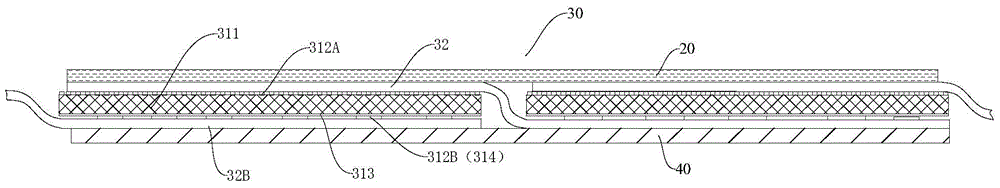

[0058] In the preparation process of the solar cell assembly 100, the conductive wire can be bonded with the sub-grid line 312 on the front side of one battery sheet 31 and the back electrode 314 on the back side of another adjacent battery sheet 31 with conductive glue to form a battery. sheet array 30 , and then stack and laminate the upper cover plate 10 , the front adhesive film layer 20 , the battery sheet array 30 , the back adhesive film layer 40 and the back sheet 50 to obtain the solar cell module 100 .

[0059] Other components of the solar cell assembly 100 according to the present application may be known in the art, and will not be repeated here.

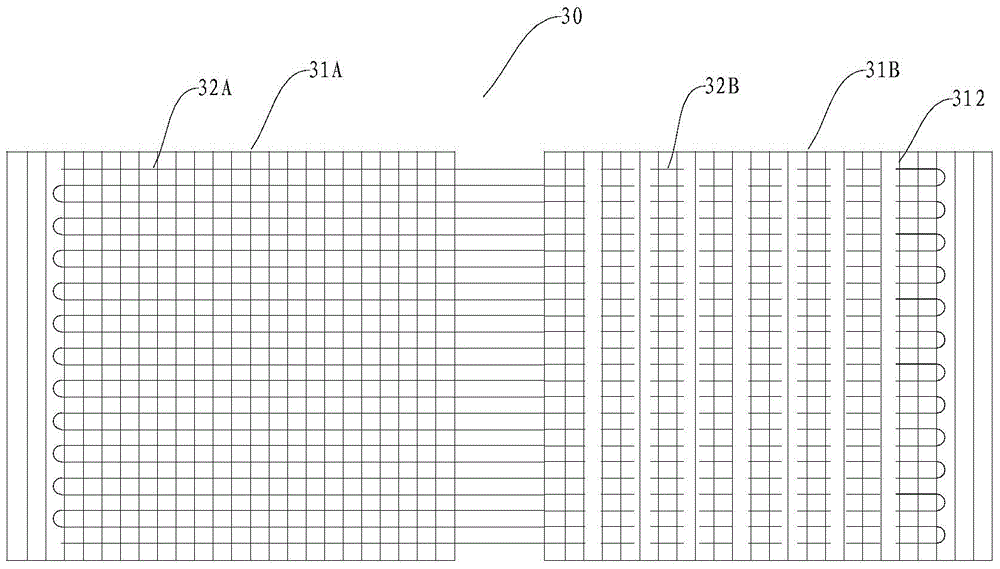

[0060] Specifically, the solar battery slice array 30 according to the embodiment of the present application includes a plurality of battery slices 31 . Adjacent battery sheets 31 are connected by a plurality of conductive wires 32 . The plurality of conductive wires 32 are composed of metal wires S extending back and ...

example 1

[0121] Example 1 is used to illustrate an example of the solar cell module 100 of the present application and its manufacturing method.

[0122] (1) Preparation of wire S

[0123] Attach a layer of epoxy resin conductive glue on the surface of the copper wire, wherein the cross-sectional area of the copper wire is 0.04mm 2, the thickness of the epoxy resin conductive adhesive is 16 μm, thereby making the metal wire S.

[0124] (2) Preparation of solar cell module 100

[0125] Provide a POE film layer with a size of 1630×980×0.5mm (melting temperature is 65°C), and accordingly provide a glass plate with a size of 1633×985×3mm and 60 pieces of polycrystalline silicon cells with a size of 156×156×0.21mm Tablet 31. The battery sheet 31 has 91 auxiliary grid lines (made of silver, with a width of 60 microns and a thickness of 9 microns), each auxiliary grid line basically runs through the battery sheet 31 in the longitudinal direction, and the distance between adjacent auxilia...

example 2

[0131] (1) Preparation of wire S

[0132] Attach a layer of acrylate conductive glue on the surface of the copper wire, wherein the cross-sectional area of the copper wire is 0.03mm 2 , the thickness of the acrylate conductive adhesive is 10 μm, thereby making the metal wire S.

[0133] (2) Preparation of solar cell modules

[0134] Provide an EVA film layer with a size of 1630×980×0.5mm (melting temperature is 60°C), a glass plate with a size of 1633×985×3mm and 60 pieces of polycrystalline silicon cells 31 with a size of 156×156×0.21mm. The light-receiving surface of the battery sheet 31 is provided with 91 auxiliary grid lines (the material is silver, the width is 60 microns, and the thickness is 9 microns), and each auxiliary grid line basically runs through the battery sheet 31 in the longitudinal direction, and two adjacent lines The distance between the auxiliary grid lines is 1.7 mm, and the back of the battery sheet 31 is provided with 5 back electrodes (the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com