Packaging assembly control system

A technology for control systems and packaging components, applied in the field of packaging, can solve the problems of different shapes and sizes, errors in detection results, and the inability of detection devices to quickly adapt to different products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

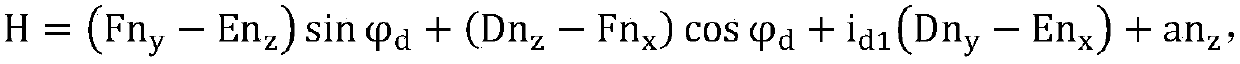

[0039] The device of the present invention comprises an induction device body 1, a total induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the induction device body 1 is detachably arranged on the base of the general induction device 5, and the bases of the sub-induction devices are installed in different positions, which is convenient for users to use. The base 5 of the total induction device is connected with a detection device. The base 5 of the overall sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-sensing devices are respectively provided with laser emitting components 6 .

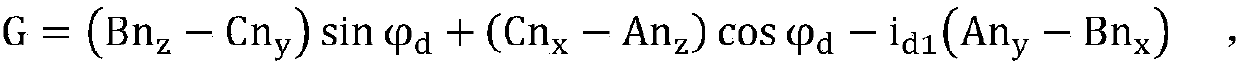

[0040] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alone. The optical rece...

Embodiment 2

[0076] The device of the present invention comprises an induction device body 1, a total induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the induction device body 1 is detachably arranged on the base of the general induction device 5, and the bases of the sub-induction devices are installed in different positions, which is convenient for users to use. The base 5 of the total induction device is connected with a detection device. The base 5 of the overall sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-sensing devices are respectively provided with laser emitting components 6 .

[0077] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alone. The optical rece...

Embodiment 3

[0113] The device of the present invention comprises an induction device body 1, a total induction device base 5 and a plurality of detachable sub-induction device bases, such as figure 1 As shown, the induction device body 1 is detachably arranged on the base of the general induction device 5, and the bases of the sub-induction devices are installed in different positions, which is convenient for users to use. The base 5 of the total induction device is connected with a detection device. The base 5 of the overall sensing device includes an optical receiving component, an infrared emitting component 22 , a distance measuring component 13 and an infrared optical processing component 12 . The bases of the sub-sensing devices are respectively provided with laser emitting components 6 .

[0114] Such as figure 2 As shown, the optical receiving component can receive laser light and infrared light at the same time, or receive laser light or infrared light alone. The optical rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com