Introducing device for longitudinal wrapping and pressing technology of metal composite belt

A technology of metal composite tape and lead-in device, which is applied in light guides, optics, instruments, etc., can solve the problems of easy separation and dislocation of the optical cable core and metal composite tape, weak overlapping of metal composite tape, and inability to limit metal composite tape. , to achieve the effect of low production cost, simple structure and improved optical cable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

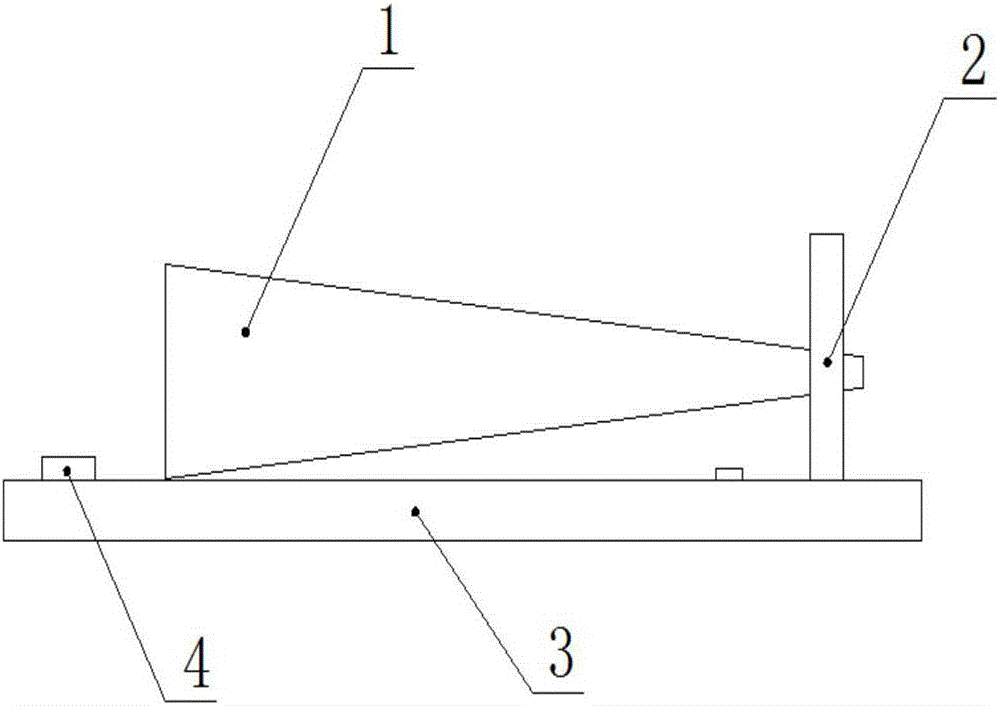

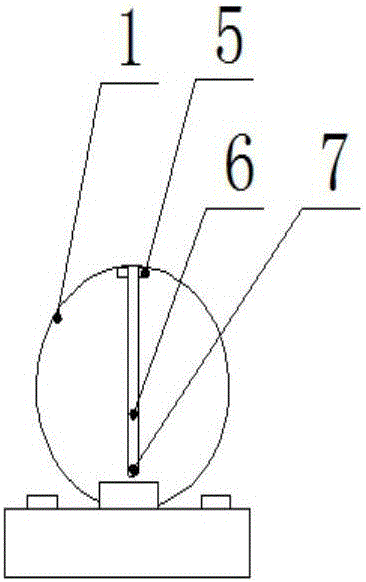

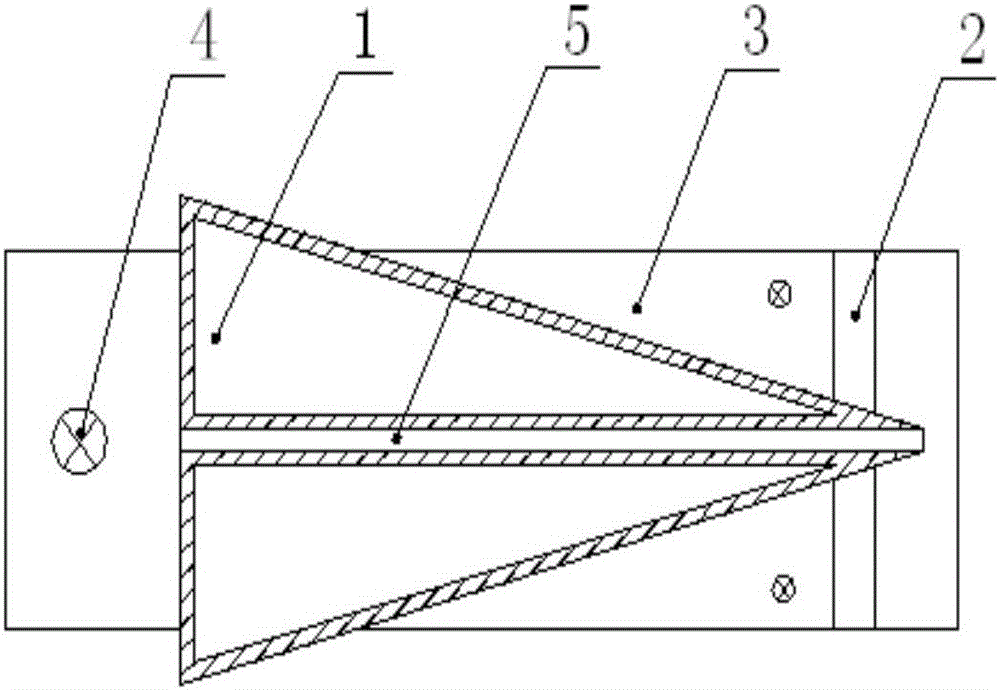

[0022] A lead-in device suitable for the longitudinal cladding process of metal composite strips, such as figure 1 As shown, it includes bottom plate 3, tube tube 1 and cavity inserting plate 6. The tube tube is a conical hollow tube with an inlet diameter larger than the outlet diameter. The limiting plate 2 on the base plate is fixed. Such as figure 2 , image 3 As shown, a longitudinal groove 5 is formed through the upper inner wall surface of the tube, and a cavity plate is movably inserted in the longitudinal groove, and the lower end of the cavity plate is integrally formed with a hole 7 suitable for the passage of the cable core. There is a gap for the passage of the metal composite strip between the lower end of the cavity plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com