Radiation-proof inductive speed sensor

A speed sensor, inductive technology, used in instruments, linear/angular velocity measurement, velocity/acceleration/shock measurement, etc., can solve the problems of difficult signal processing, long signal lines, and easy signal interference, and achieves a simple overall structure. The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

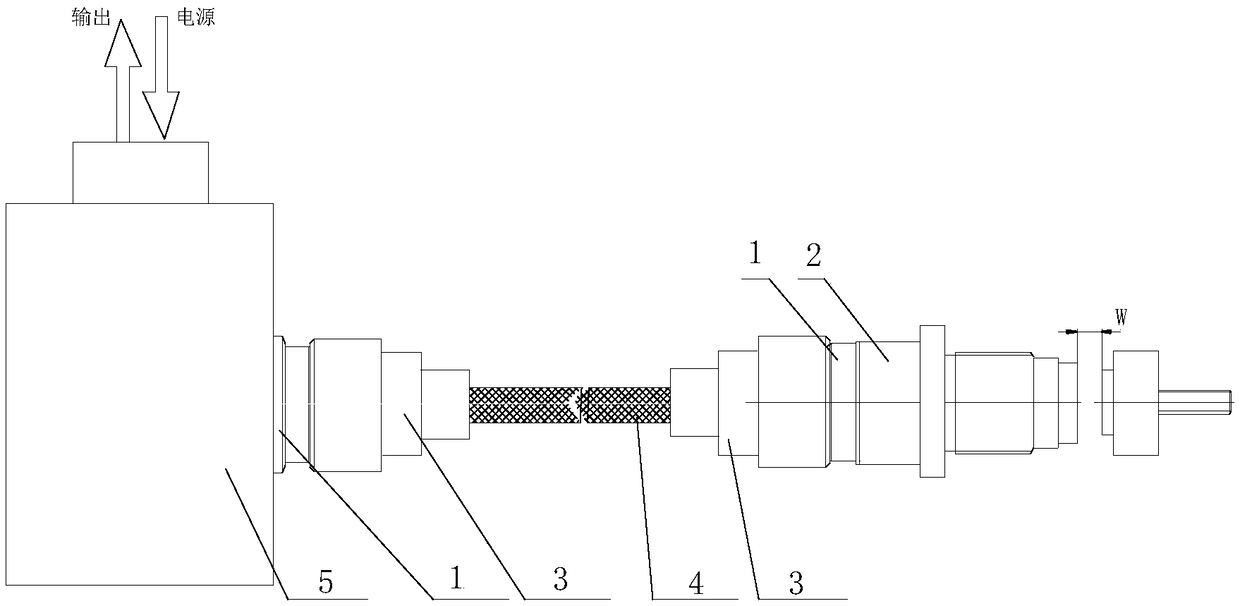

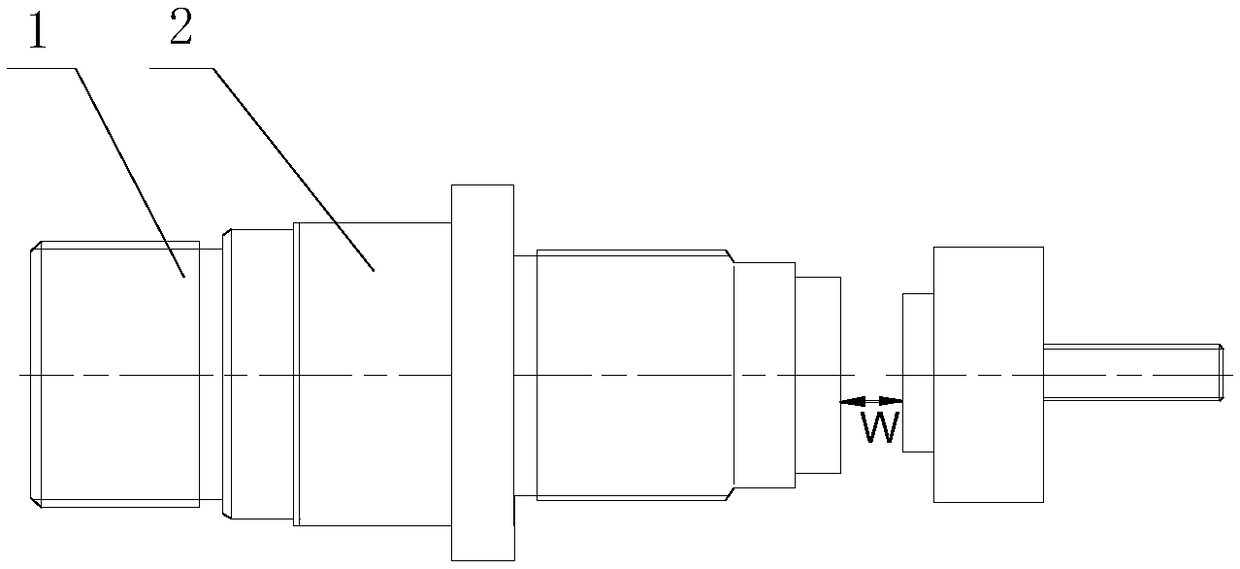

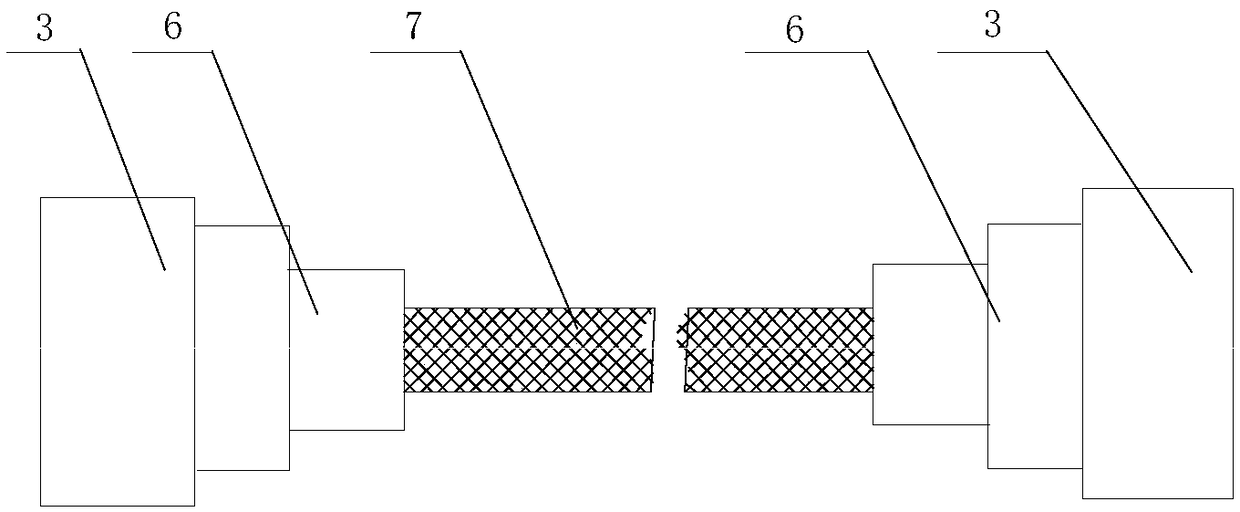

[0023] refer to Figure 1-Figure 3 . The radiation-proof inductive speed sensor mainly consists of three parts: figure 2 Inductive speed measuring probe shown, image 3 cable assemblies shown, Figure 4-6 The control box shown, and placed in the radiation-proof chamber of the control box, connected to the power block and connected in series Figure 4 The detection circuit, level conversion circuit, frequency measurement circuit and output interface circuit are shown. figure 2 The rotation number measurement probe shown can be an inductive rotation number measurement probe. It is determined that the probe is in the air gap (that is, the working air gap) and W is the critical air gap. It is determined that W is 3mm-4mm. When the air gap is 4mm, the probe output The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com