Hydrostatic test device for testing cable cores of submarine optical cables

A technology for submarine optical cable and hydrostatic testing, which is applied to measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve problems such as inconvenient opening and sealing, save testing time, and achieve reasonable structural design. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

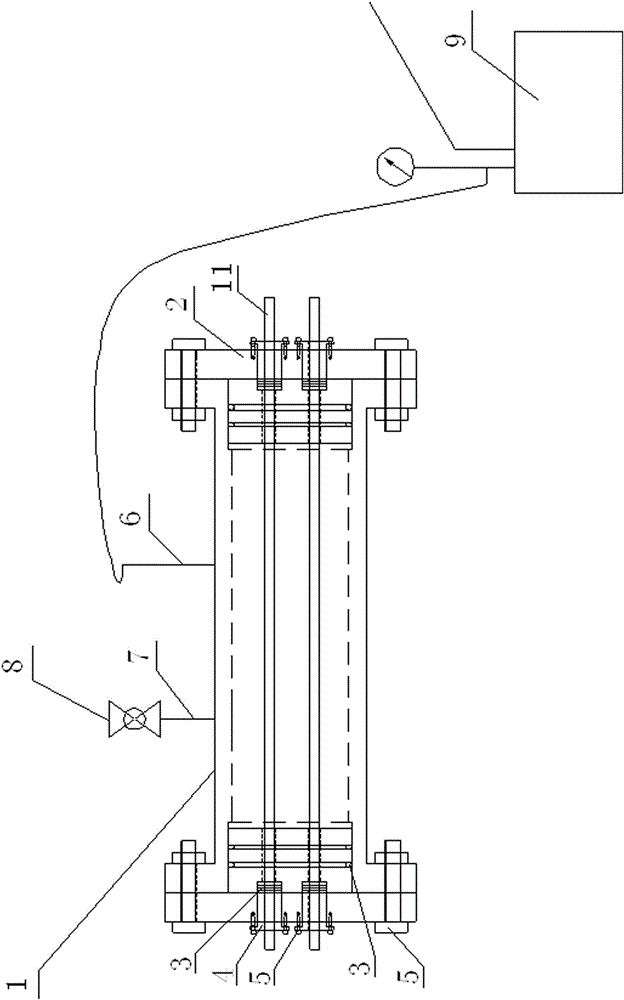

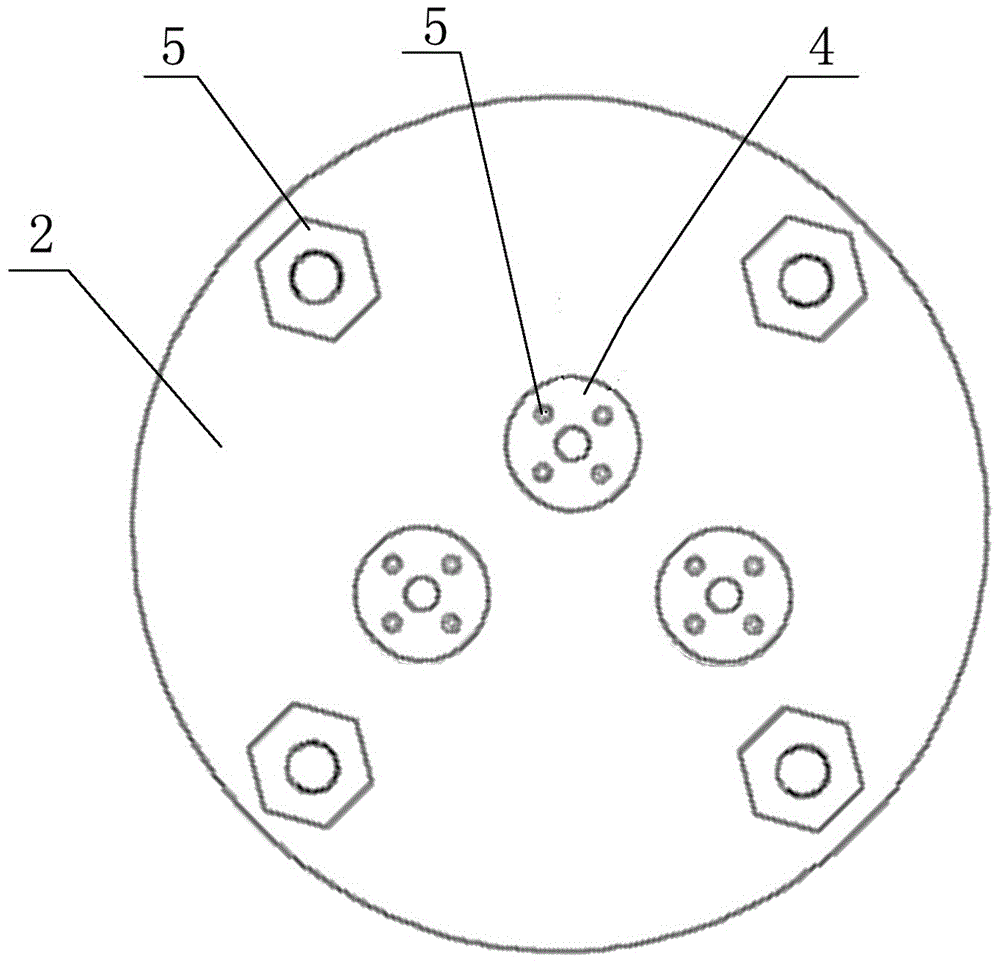

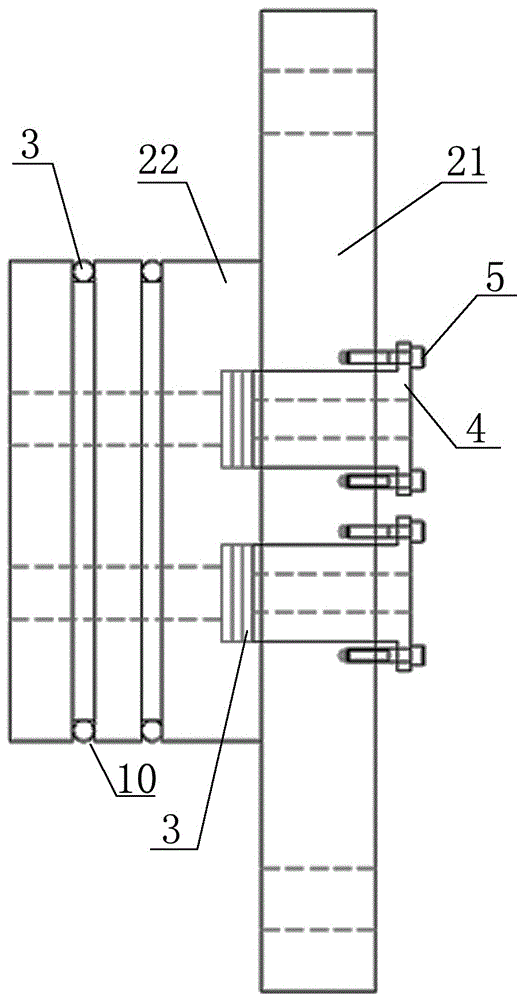

[0014] like Figure 1 to Figure 5 As shown in the figure, a hydraulic test device for the core test of submarine optical cable includes a cylinder body 1, a T-shaped cover plate 2 and a plug 4. Both ends of the cylinder body 1 are open, and the T-shaped cover plate 2 is closed on the cylinder. The two ends of the body 1 are fixed with bolts 5, the T-shaped cover is provided with a plurality of countersunk holes (3 in this embodiment), and the plug 4 is located in the countersunk holes on the T-shaped cover 2 and is provided with bolts 5. Fixed, the plug 4 is a through-hole structure for penetrating the submarine optical cable core 11, the outer surface of the cylinder 1 is welded with a high-pressure water inlet pipe 6 and a drainage pipe 7, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com