Air tightness detecting device and servo control method thereof

An air tightness detection and to-be-detected technology, which is used in measuring devices, fluid tightness testing, and liquid tightness measurement using liquid/vacuum degree, etc. Low problems, to achieve good economy, simple structure, avoid pressure shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

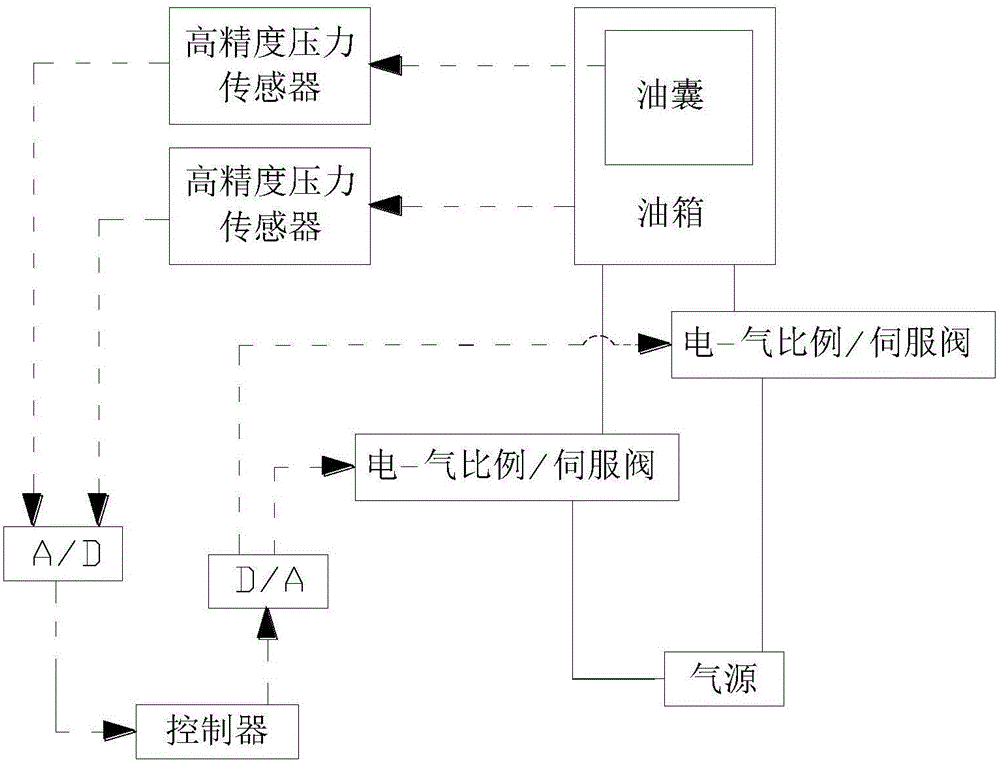

[0052] Take the fuel system airtight test as an example, such as figure 1 As shown, the servo control method of the airtight detection device includes two pressure control loops.

[0053] The first pressure control loop includes a pressure source (i.e. the first air source), an electro-pneumatic proportional / servo valve, a controlled cavity—an oil bag, a high-precision pressure sensor, an analog / digital conversion, and a digital controller. In the first pressure control system, the controlled object is the oil bag; the actuator is the electric-pneumatic servo device (that is, the first electric-pneumatic proportional / servo valve); the feedback element is a high-precision pressure sensor; the digital controller is the control element .

[0054] The process of air pressure control is essentially the inflation and deflation process of the controlled cavity, and the air pressure in the controlled cavity is adjusted by adjusting the total amount of air in the controlled cavity thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com