Photoelectric through-beam turbine flowmeter and its probe embedded injection molding process

It is a photoelectric opposite-radiation and turbine technology, which is used in liquid/fluid solid measurement, measurement of flow/mass flow, volume/mass flow generated by mechanical effects, etc. It can solve the problem of harmful magnetic materials, increase the workload of installation and development, and expand water leakage. Risks and other issues, to avoid pollution, reduce the risk of liquid leakage, and reduce the difficulty of secondary development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose and advantages of the technical solution of the present invention clearer, the present invention will be further described in conjunction with the accompanying drawings.

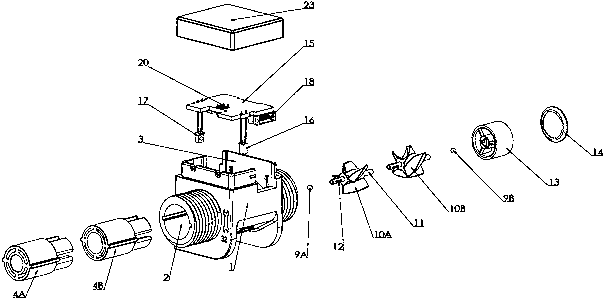

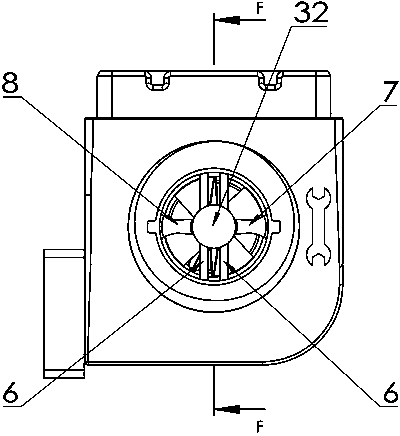

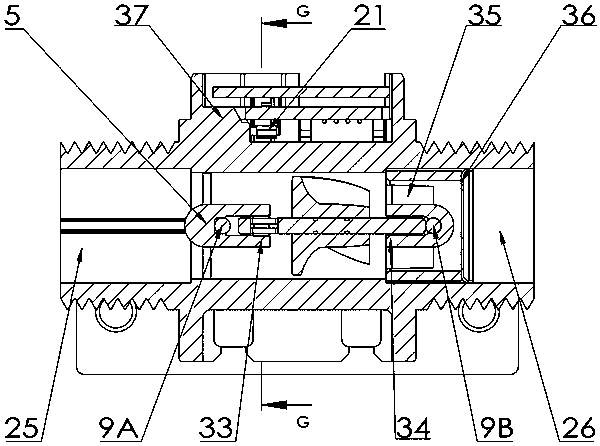

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the structure of the present invention includes: the housing 1 is composed of two major functional parts, the fluid conduit 2 and the data transmission chamber 3, and the data transmission chamber 3 bridges the upper part of the fluid conduit 2 and wraps it from both sides of the fluid conduit 2 The fluid conduit 2 provides the required light path for the photoelectric transceiver tube on the transmission control board 15; from the fluid inlet 25 of the fluid conduit 2 to the fluid outlet 26, there are successively equipped with a multifunctional front guide frame 5, an impeller assembly, The diversion plug assembly and the collar 14; the multifunctional front guide frame 5 is composed of a probe 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com