Liquid explosive detonating method adopting hole bottom air cushion

A technology of liquid explosives and detonation methods, applied in the field of blasting, can solve problems such as reducing the depth and quantity of broken rocks, increasing operating costs, affecting construction progress, etc., achieving high energy utilization, reducing dosage, and avoiding the effect of leaving foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

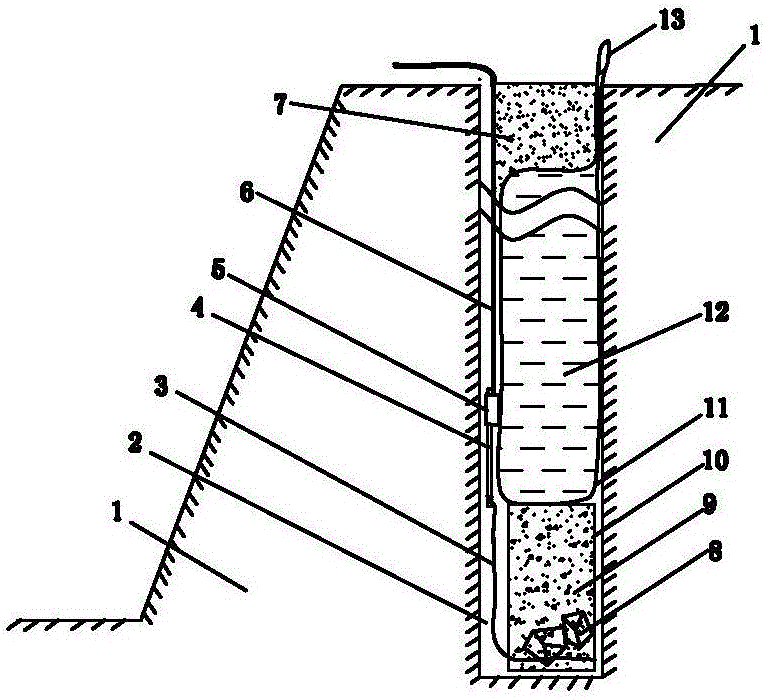

[0019] Such as figure 1 Shown, a kind of liquid explosive hole bottom air cushion detonation method of the present invention is characterized in that comprising the following steps:

[0020] (1) Drill a medium-deep hole 2 at a suitable position on the rock 1;

[0021] (2) Put the air cushion bag 10 equipped with light foam filling 9 and earth and rocks 8 into the bottom of the middle-deep hole 2, fix a section of detonating cord 4 on the upper end of the air cushion bag 10, or bind it with a rope 3, The detonating cord 4 is tied with a detonator 5, the detonator 5 is connected with a detonator 6, and the detonator 6 extends above the ground;

[0022] (3) Put the bottom-sealed plastic film tube 11 into the middle and deep hole 2;

[0023] (4) Fill the liquid explosive 12 into the plastic film tube 11;

[0024] (5) Fill the medium-deep hole outside the plastic film tube 11 above the liquid explosive 12 with crushed soil 7 until the hole is filled up;

[0025] (6) Use a deton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com