Tensioner installing support

A technology for installing brackets and tensioners, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of cumbersome processing and complex tensioner installation structure, etc., achieve good manufacturability, save mold costs and management costs, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in detail with reference to the accompanying drawings and specific embodiments, but not as a limitation to the present invention.

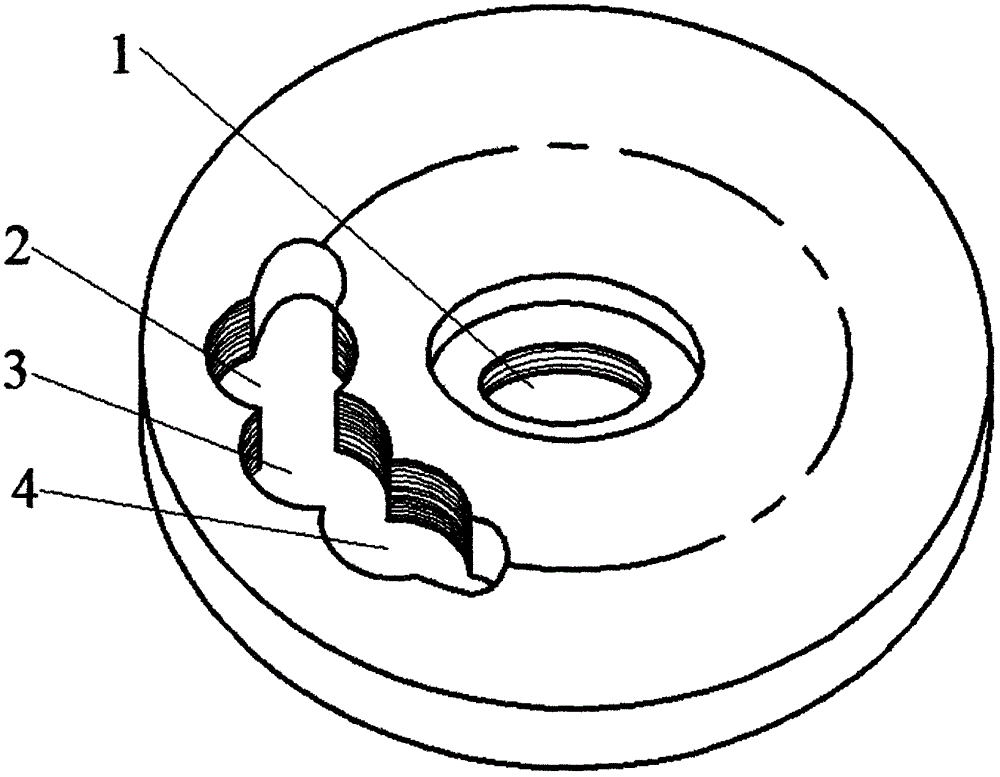

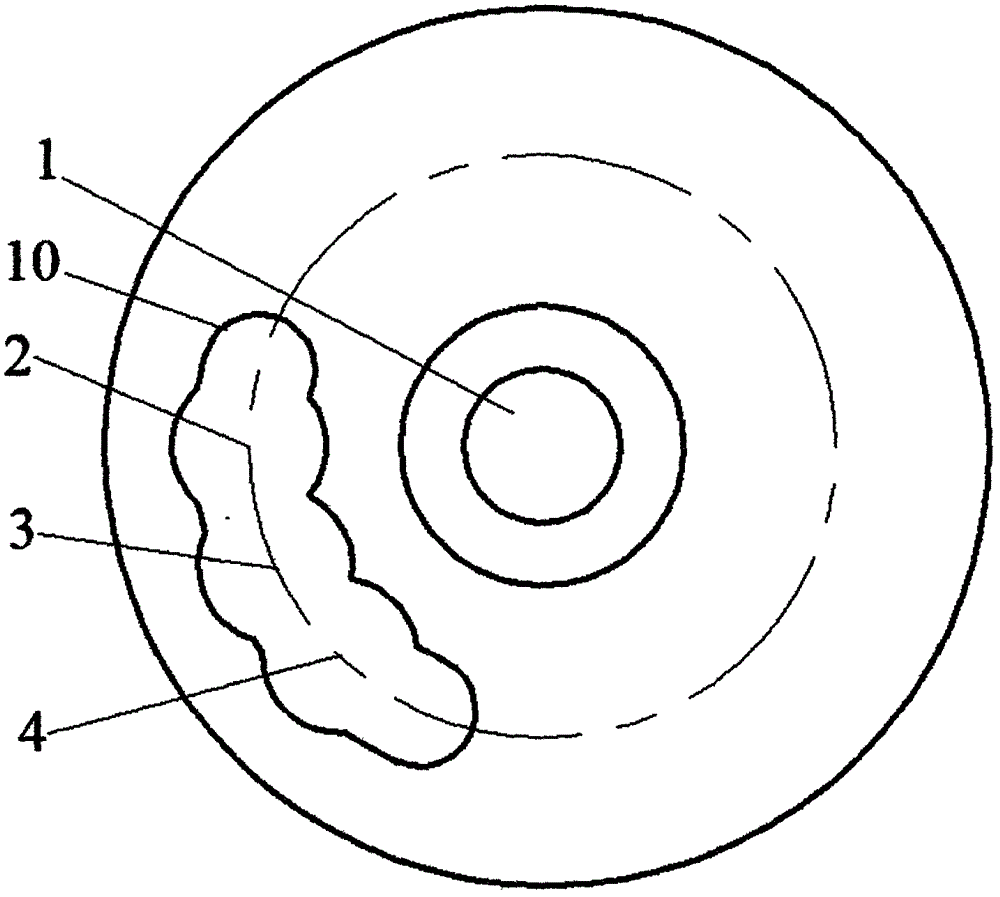

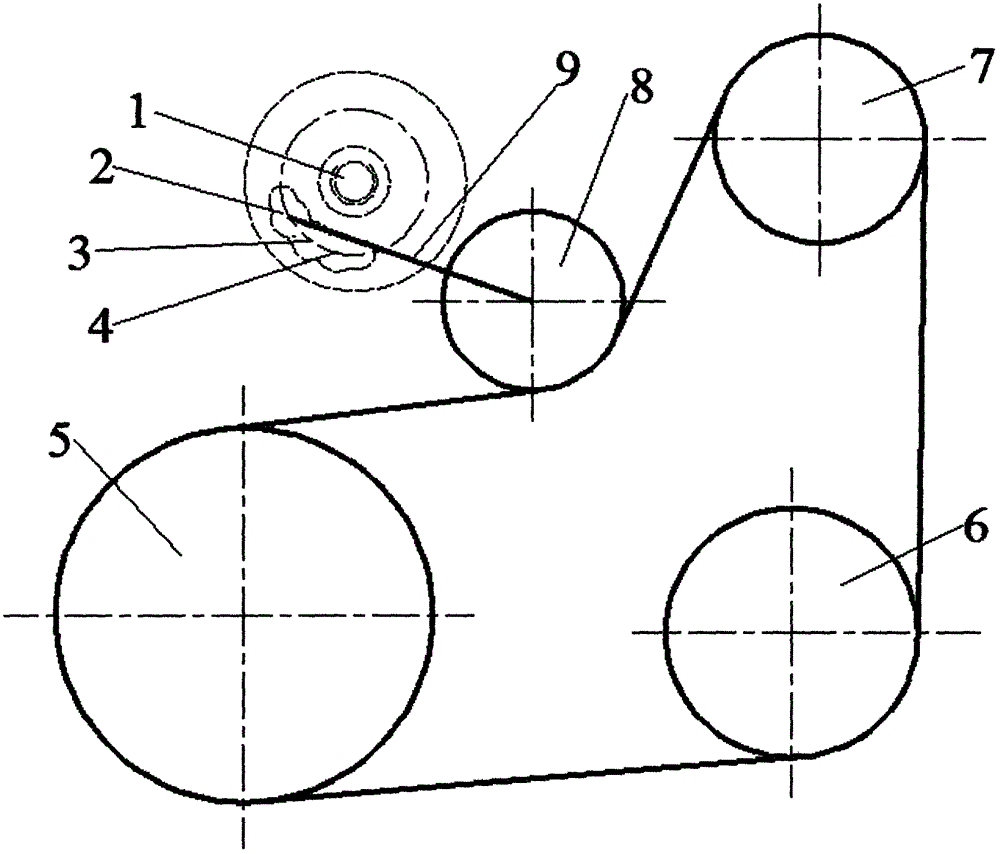

[0021] Reference Figure 1~3 , A mounting bracket for a tensioner in an embodiment of the present invention includes a bracket body for installing the tensioner, and the bracket body is provided with:

[0022] A bracket mounting hole 1 with threads on the bracket mounting hole 1;

[0023] A circular arc waist-shaped hole 10, the circular arc waist-shaped hole 10 is provided with three tensioner installation holes (respectively the tensioner installation hole 2, the tensioner installation hole 3 and the tensioner installation hole 4), The tensioner installation hole is provided with threads.

[0024] The bracket mounting hole 1 is on a plane lower than the tensioner mounting hole, and the tensioner mounting hole 2, the tensioner mounting hole 3, and the tensioner mounting hole 4 on the circular waist-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com