A directional piercing tool and process for insoluble balls used to open sliding sleeves

An insoluble and high-tech technology, applied in the field of directional shooting tools and technology, can solve the problems of insoluble ball stuck and unable to flow back, and achieve the effect of good application effect, strong practicability and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

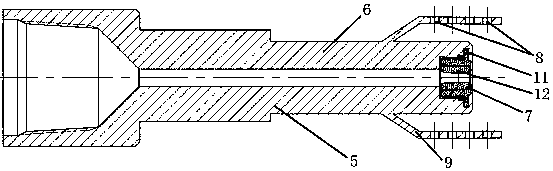

[0031] Such as figure 1 The structure diagram of the directional injection tool for the insoluble ball for opening the sliding sleeve of the present invention is shown. It includes a positioning block 6 and a nozzle 7. The nozzle 7 is connected to the bottom port of the positioning block 6 and the positioning block 6 is connected to one end of the nozzle 7. Positioning legs 9 are provided on the surrounding outer walls.

[0032] The positioning leg 9 is a cylindrical structure. The diameter of the cylinder is larger than the diameter of the bottom end of the positioning block 6, larger than the diameter of the insoluble ball to be processed, and smaller than the inner diameter of the pitching sleeve 10 that contains the insoluble ball to be processed, and is positioned One end of the leg 9 is a closed end, and the closed end of the positioning leg 9 is fixedly connected with the outer wall of the positioning block 6 to form an integrated structure. When the positioning block 6 is ...

Embodiment 2

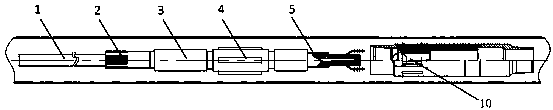

[0039] A directional injection tool string with insoluble balls for opening the sliding sleeve, such as figure 2 As shown, it includes the coiled tubing 1, the outer slip connector 2, the variable buckle joint 3, the elastic centralizer 4, and the directional injection tool 5 connected in sequence from top to bottom.

[0040] The coiled tubing 1 and the outer slip connector 2 are directly connected by the outer slips. Here, the coiled tubing 1 and the outer slip connector 2 are not allowed to use threaded connection. The outer slip connector 2, the variable buckle joint 3, the elastic centralizer 4 and the directional injection tool 5 are all connected by threads, which is convenient for disassembly and replacement.

[0041] The parts and structures not described in detail in this embodiment, such as the coiled tubing 1, the outer slip connector 2, the variable buckle joint 3, and the elastic centralizer 4, are well-known parts and common structures in the industry, and only need ...

Embodiment 3

[0043] A directional shooting and penetration process of insoluble balls for opening a sliding sleeve, which includes the following steps:

[0044] Step 1. Install the directional injection tool with nozzle 7 on the ground;

[0045] Step 2. Connect the coiled tubing 1, the outer slip connector 2, the variable buckle connector 3, the elastic centralizer 4, and the directional injection tool 5 from top to bottom to form a directional injection tool string;

[0046] Step 3. Lower the directional injection tool string formed by the connection in step 2 to the predetermined well depth position;

[0047] Step 4. After entering the predetermined well depth position, start the pump truck of coiled tubing 1 and circulate with a displacement of 400~500L / min. After the circulation is stable, the displacement will be increased to 800~1000L / min, and the sand concentration will be 100~120kg / m 3 The sand-carrying liquid passes through the nozzle 7 of the directional injection tool to form a high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com