Coiled tubing falling-prevention device and usage method thereof

An anti-dropping and tubing technology, applied in drilling pipe, casing, earth-moving drilling, etc., can solve the problems of coiled tubing falling into the well, blowout out of control, coiled tubing loosening, etc., achieving easy processing and assembly, and convenient use and operation , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

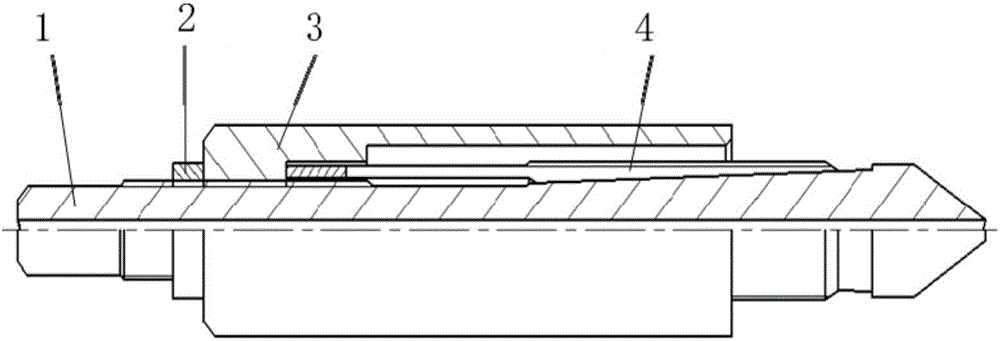

[0033] The embodiment of a coiled tubing anti-drop device of the present invention is as follows:

[0034] Before field use, complete the assembly of the coiled tubing drop prevention device according to the instructions: first, insert the slotted slip 4 from the upper end of the spear-shaped central rod 1, and then insert the spear-shaped central rod 1 into the limit protection tube 3 Inside, after adjusting the relative position of the spear-shaped central rod 1 and the limit protection tube 3 through the screw thread on the spear-shaped central rod 1, screw the back cap 2 on the upper part of the spear-shaped central rod 1 and tighten it, that is, assemble Finished coiled tubing drop prevention device.

[0035] When the coiled tubing is working in the tubing, and it breaks off for some reason and gets stuck in the tubing, the broken coiled tubing cannot be fished out with conventional fishing tools, and the coiled tubing can only be taken out by pulling the tubing. The coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com