A waterproof and thermal insulation exterior wall block with water release structure

A technology for insulating exterior walls and blocks, which is applied in building components, building structures, building materials, etc., can solve the problems of rough exterior wall blocks, poor waterproof performance of blocks, and infiltration of rainwater in walls, and achieves the goal of building masonry and The effect of saving decorative materials, good waterproof and heat insulation effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical scheme and technical effect of the present invention more obvious and easy to understand, the following will be described in detail in conjunction with the accompanying drawings.

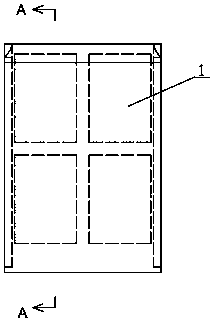

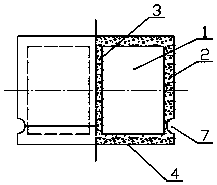

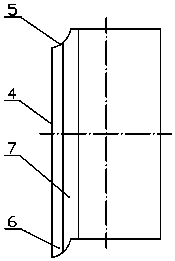

[0014] Such as Figure 1 to Figure 5 As shown, a waterproof and thermal insulation exterior wall block with a drainage structure of the present invention mainly includes a polystyrene mandrel 1 with a rectangular shape. A layer of thin reinforced concrete layer 2 is poured on the six surfaces of the polystyrene mandrel to form an outer wall block filled with thermal insulation material.

[0015] The polystyrene mandrel 1 is provided with several through holes or through grooves, and the said several through holes or through grooves are staggered along the longitudinal, transverse and vertical directions of the polystyrene mandrel so as to facilitate the pouring of the outer reinforced concrete layer. When the concrete connecting rod or connecting plate 3 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com