An energy-saving and leak-proof curtain wall system

A curtain wall and leak-proof technology, applied to walls, buildings, building components, etc., can solve the problems of unfavorable application and development, insufficient installation precision, low construction efficiency, etc., and achieve the effect of convenient and convenient construction, less processing amount and rapid installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

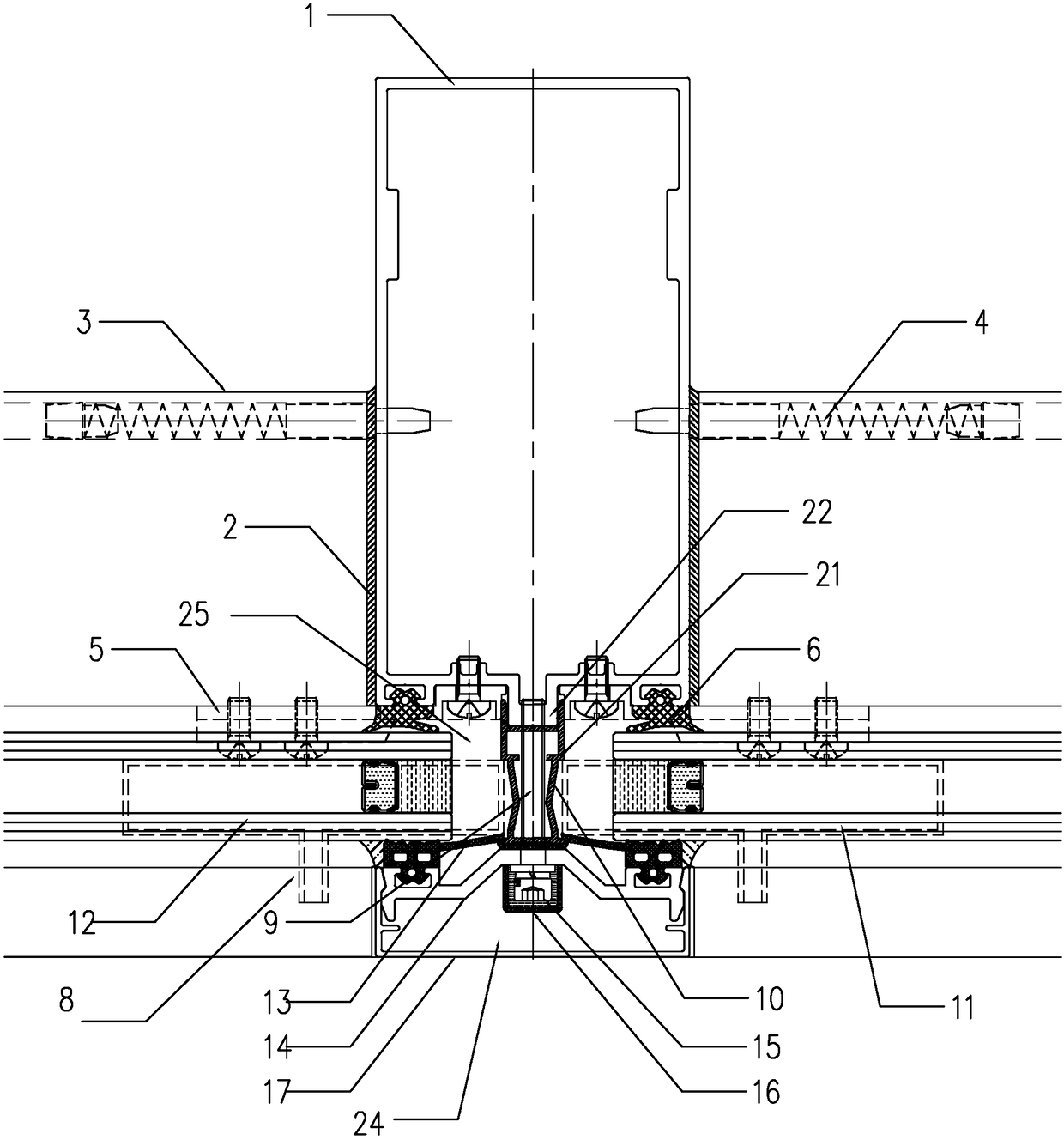

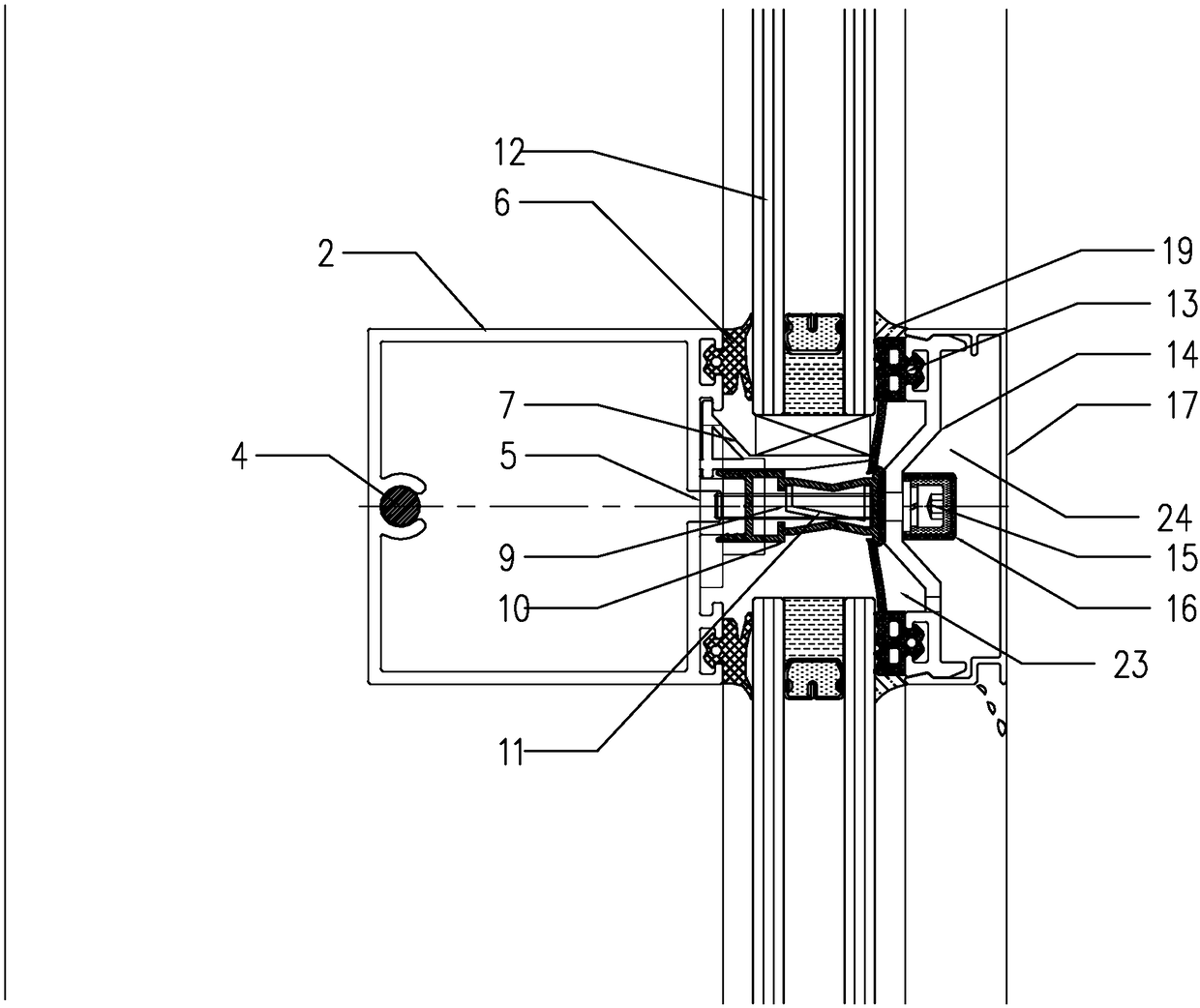

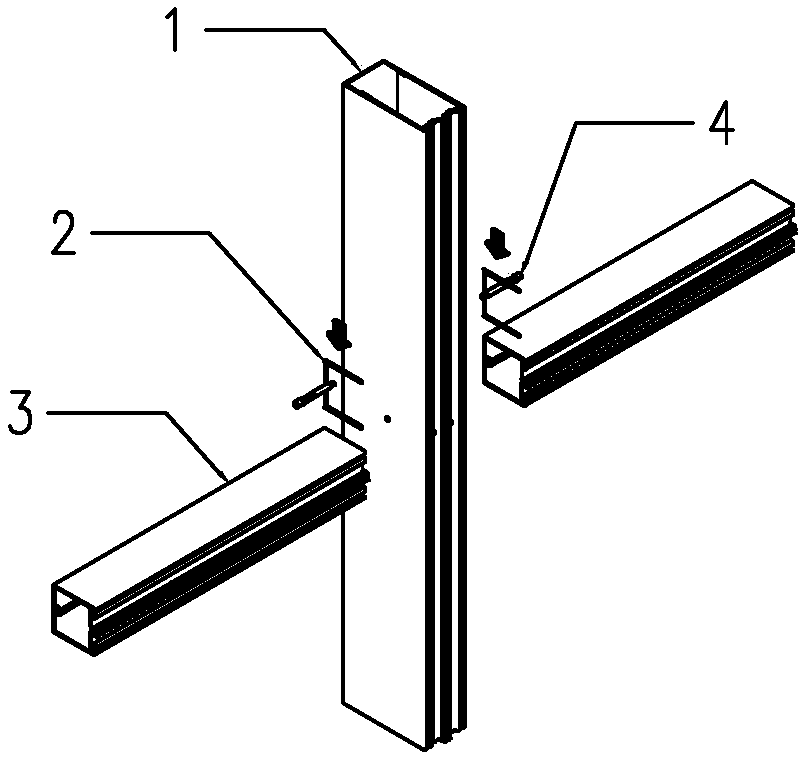

[0041] Embodiment 1. The column adapter part 18 and the beam adapter part 20 of the connector are arranged in a straight line, and are used to install the column 1 and the beam 3 whose connection surfaces are on the same horizontal plane.

Embodiment 2

[0042] Embodiment 2. A transition surface 57 is provided between the column adapter part 18 and the beam adapter part 20 of the connector, and the connector 5 with the transition surface 57 is formed into a stepped shape. The transition surface is used to connect the column 1 The fitting part is located in front of the crossbeam fitting part 20 and is suitable for being installed on the connection surface where the column protrudes from the crossbeam 2 .

Embodiment 3

[0043] Embodiment 3: A transition surface 57 is provided between the column adapter part 18 and the beam adapter part 20 of the connector, and the transition surface 57 of the connector 5 is used to position the column adapter part behind the beam adapter part; It is suitable for installation on the connection surface where the column 1 is recessed in the beam 3.

[0044] The outdoor rubber strip 13 is integrated, and two ends of the outdoor rubber strip 13 are respectively connected to adjacent glass plates 12 . The outdoor rubber strip 13 and the inner side of the pressure plate 14 form a leak-proof partition cavity 23 , and a bayonet is provided at the connection between the integral rubber strip and the heat insulation frame 10 .

[0045]The heat insulation frame 10 includes a strip heat insulation strip and a water collection tank 11 , and the heat insulation frame 10 at the seam of the glass plates 12 directly in front of the beam 3 is provided with the water collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com