Washing machine and control method

A washing machine and washing water technology, applied in the field of washing machines, can solve the problems that the stirring water flow cannot be too strong, affect the normal progress of the flocculation reaction, and cannot remove flocs, etc., and achieve the effects of being suitable for popularization and use, simple in structure, and improved in cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

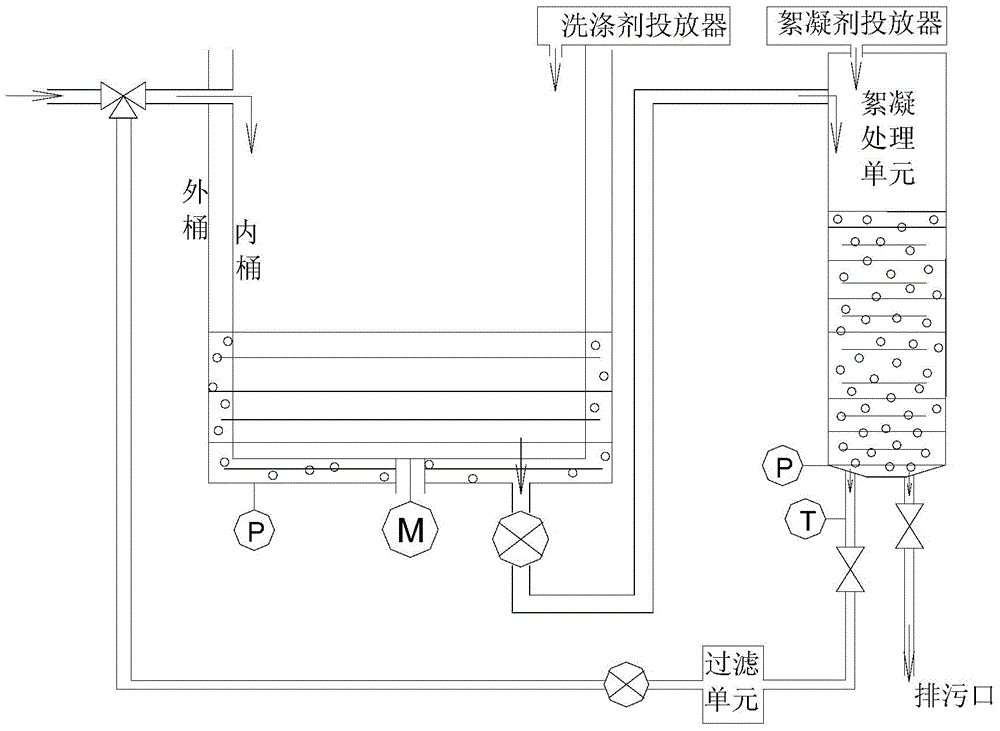

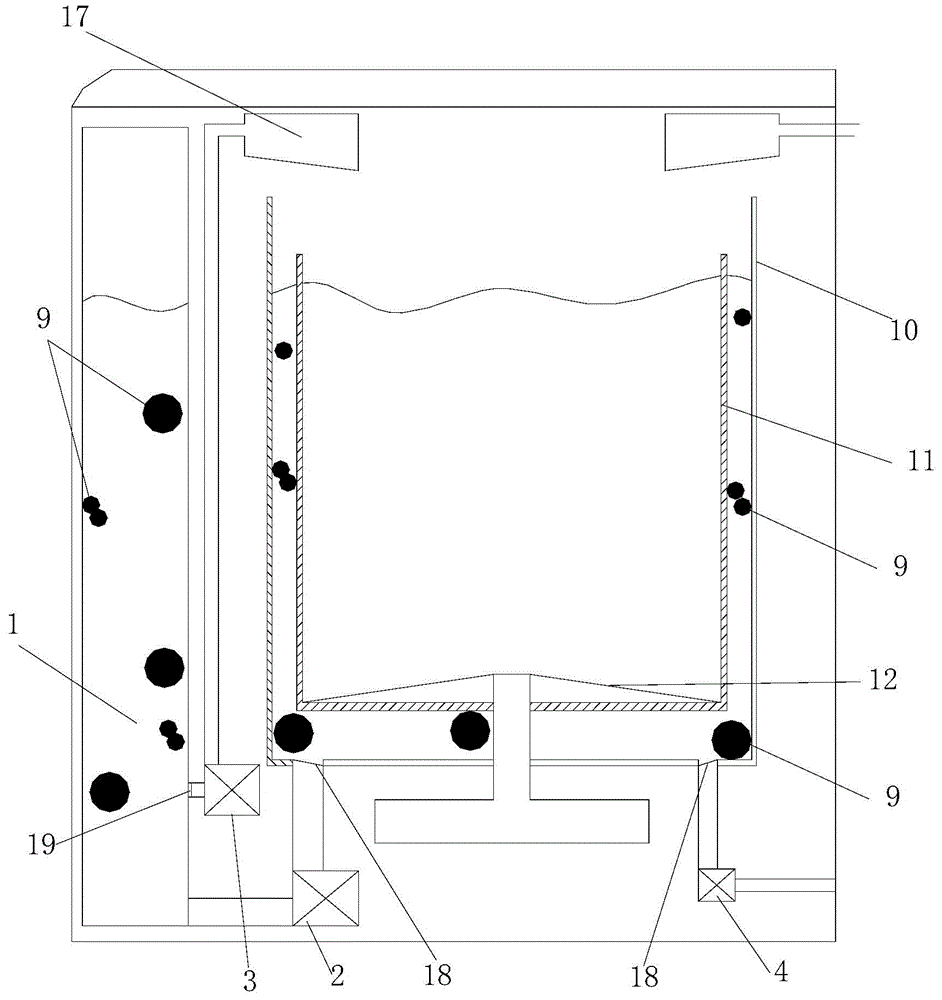

[0046] Such as Figure 1 to Figure 4 As shown, in this embodiment, the flocculation bucket 1 is provided with a plurality of cleaning fluff balls 9 to remove flocs attached to the flocculation bucket.

[0047] Such as Figure 4 As shown, in this embodiment, the cleaning hair ball 9 has a plurality of strip-shaped cleaning hairs 15; one end of each cleaning hair 15 is fixed to form the center of the cleaning hair ball 9, and the other end diverges to form the cleaning hair ball 9 of the outer contour. In this embodiment, each cleaning hair 15 can be integrally formed to form a cleaning hair ball 9 ; one end of each cleaning hair 15 can also be adhered and fixed to form a cleaning hair ball 9 .

[0048] In this embodiment, the outer contour surface of the cleaning hair ball 9 may be spherical, square, ellipsoidal, cylindrical, regular tetrahedron or other irregular clusters.

[0049] In this embodiment, the cleaning hairs 15 provided on the cleaning hair ball 9 are arranged a...

Embodiment 2

[0054] In this embodiment, a control method for cleaning the flocculation barrel of a washing machine is introduced, which includes the following steps: water is poured into the flocculation barrel and the stirring mechanism is started, so that the cleaning hair balls move with the stirring water flow, and the flocculation attached to the flocculation barrel things to clean up.

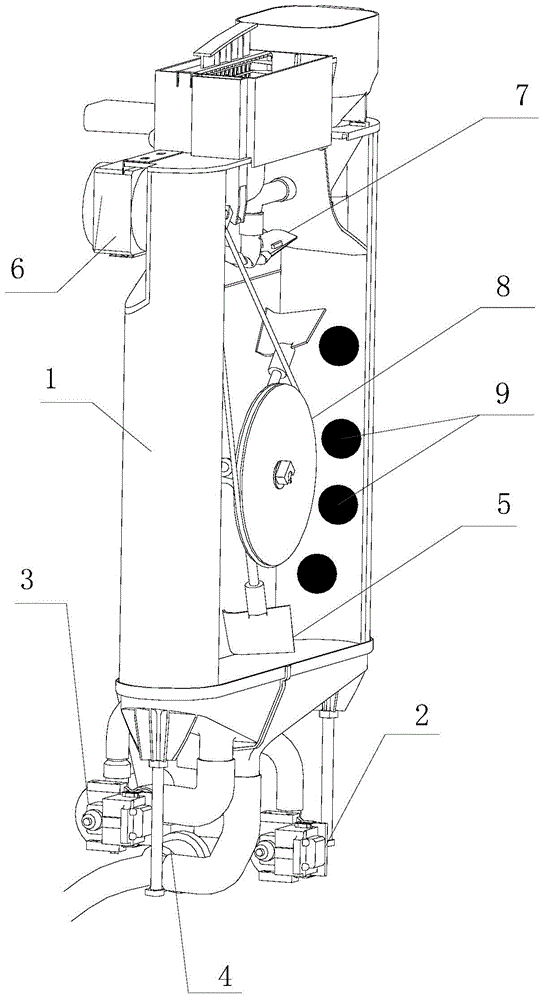

[0055] In order to realize the above method, in this embodiment, a stirring device for stirring the water in the flocculation bucket 1 is provided. The stirring device can be any structure in the prior art, which can stir the water in the flocculation bucket for stirring. For example: if image 3 As shown, a stirring mechanism for a flocculation bucket, the stirring mechanism includes a rotating shaft horizontally arranged in the flocculation bucket 1, a belt pulley 8 that rotates vertically around the rotating shaft is installed on the rotating shaft, and the belt pulley 8 extends radially with a pl...

Embodiment 3

[0059] In this embodiment, the flocculation barrel 1 is provided with at least one discharge port, so that the water in the flocculation barrel 1 flows out from the discharge port. A blocking structure is provided at the discharge port, and / or the pore size of the discharge port is smaller than the particle diameter D of the cleaning hair ball 9, so as to prevent the cleaning hair ball 9 from flowing out of the flocculation barrel 1 along with the drainage.

[0060] Such as image 3 As shown, in this embodiment, the discharge outlet includes a sewage outlet located at the bottom of the flocculation bucket 1 and connected to the outside of the washing machine, and a sewage outlet located near the bottom of the flocculation bucket 1 to return clean water to the outer bucket 10 of the washing machine. backwater port.

[0061] In this embodiment, the blocking structure can be a plurality of ribs extending radially along the discharge opening, and each rib is arranged crosswise to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com