Pit-mud free strong-flavor liquor preparation method

A technology of Luzhou-flavor liquor and pit mud, which is applied in the preparation of non-pit mud Luzhou-flavor liquor and in the field of wine making, which can solve the problems of reduced production efficiency of raw wine, increased purification cost, and long brewing cycle, and achieves the elimination of bad Influence, processing cost saving, economical cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

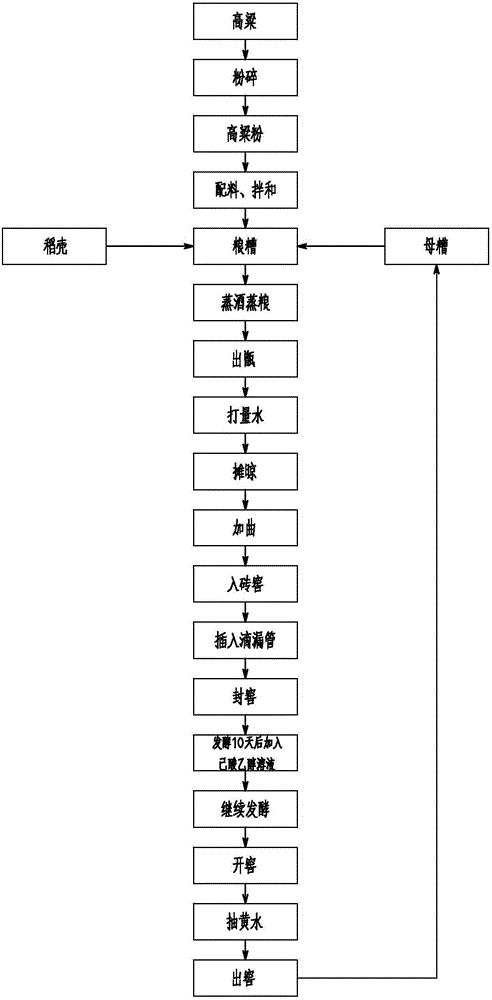

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0026] Such as figure 1 Shown, the preparation method of non-pit mud Luzhou-flavor liquor of the present invention, concrete method is:

[0027] (1) sorghum is pulverized into sorghum flour;

[0028] (2) adding ingredients to the sorghum flour, and mixing the sorghum flour and the ingredients evenly to form raw materials;

[0029] (3) The raw materials are mixed with rice husk and mother's grains to form grain grains;

[0030] (4) Carry out steaming wine steaming grain to grain grain;

[0031] (5) Make it out of the retort after steaming the grain grains with wine and grain;

[0032] (6) measure the grain grains after steaming wine and grain;

[0033] (7) After measuring the water, spread the mixture of grain grains and water;

[0034] (8) adding music after spreading;

[0035] (9) put the mixture after adding koji into the brick cellar;

[0036] (10) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com