Process for preparing baking-free ecological brick from garbage burning fly ash

A technology for waste incineration fly ash and ecological bricks, which is applied in the technological field of waste incineration fly ash to prepare non-burning ecological bricks, and achieves the effects of short disposal period, high efficiency and high waste rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (6) Take 10 parts by weight of waste incineration fly ash and grind it through a 100-mesh sieve, put it in a container, add 5 parts by weight of sodium hydroxide and 20 parts by weight of water, mix and react at 20°C for 3 hours. Continue to add 90 parts by weight of P.O32.5 ordinary Portland cement, place in a mixer at 50 rpm, and stir for 5 minutes. The mixture was poured into the ecological brick mold and vibrated for 1 minute at a vibration frequency of 50 times / min. The mold that has finished grouting is covered with a layer of plastic wrap, placed in a constant temperature and humidity climate box with a humidity of 95% at 20°C and maintained for 48 hours before removing the mold. The brick body after demoulding is placed in a water curing box at 20°C for 28 days to obtain an ecological brick. The compressive strength of the prepared ecological brick is 34.4MPa.

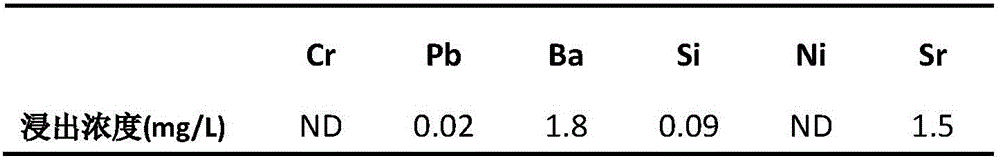

[0024] The ecological brick prepared in Example 1 was tested for heavy metal leaching, and the resu...

Embodiment 2

[0029] (7) Take 40 parts by weight of waste incineration fly ash and grind it through a 100-mesh sieve, put it in a container, add 15 parts by weight of sodium hydroxide and 40 parts by weight of water, mix and react at 20°C for 3 hours. Continue to add 60 parts by weight of P.O42.5 ordinary Portland cement, place it in a mixer at 200 rpm, and stir for 2 minutes. The mixture was poured into the ecological brick mold and vibrated for 2 minutes at a vibration frequency of 20 times / min. The mold that has finished grouting is covered with a layer of plastic wrap, placed in a constant temperature and humidity climate box with a humidity of 80% at 40°C and maintained for 48 hours before removing the mold. The brick body after demoulding is placed in a water curing box at 60°C for 28 days to obtain an ecological brick. The compressive strength of the prepared ecological brick is 47.6MPa.

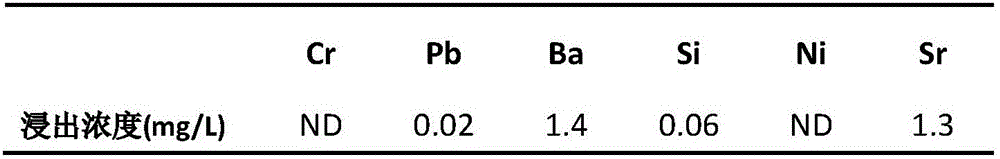

[0030] The ecological brick prepared in Example 2 was tested for heavy metal leaching, and th...

Embodiment 3

[0035] (8) Take 30 parts by weight of waste incineration fly ash and grind it through a 100-mesh sieve, put it in a container, add 5 parts by weight of sodium hydroxide and 30 parts by weight of water, mix and react at 50°C for 0.5h. Continue to add 70 parts by weight of P.O52.5 ordinary Portland cement, place in a mixer at 200 rpm, and stir for 5 minutes. The mixture was poured into the ecological brick mold and vibrated for 1 minute at a vibration frequency of 50 times / min. The mold that has finished grouting is covered with a layer of plastic wrap, placed in a constant temperature and humidity climate box with a humidity of 90% at 30°C and maintained for 14 hours before removing the mold. The brick body after demoulding is placed in a water curing box at 50°C for 21 days to obtain an ecological brick. The compressive strength of the prepared ecological brick is 56.4MPa.

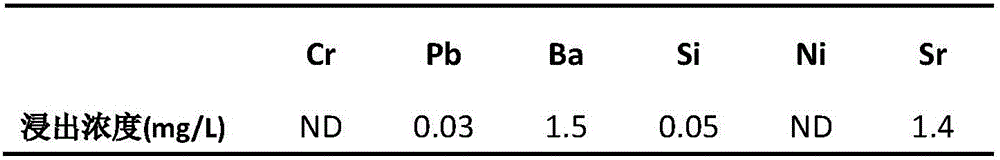

[0036] The ecological brick prepared in Example 3 was tested for heavy metal leaching, and the result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com