Method for preparing low-residual-aluminum polyaluminum chloride

A polyaluminum chloride, low-residue technology, applied in aluminum chloride, chemical instruments and methods, aluminum halides, etc., to achieve guaranteed flocculation effect, excellent flocculation effect, and reduction of residual aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

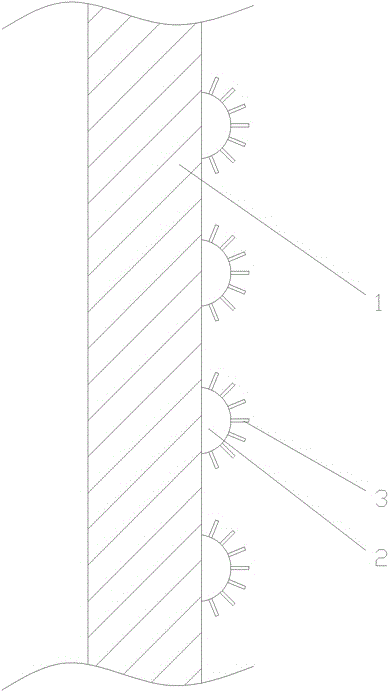

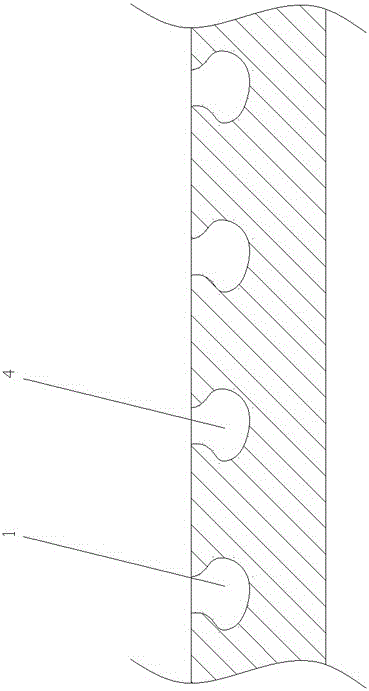

Image

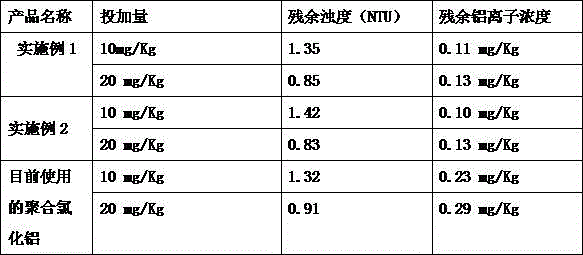

Examples

Embodiment 1

[0024] Embodiment 1: the preparation method of the polyaluminum chloride of a kind of low residual aluminum of this example, its steps are:

[0025] Add 5 tons of hydrochloric acid with a concentration of 15% and 570Kg of aluminum hydroxide in the 10000L reactor, which contains Al 2 o 3 % is 64% (m / m), and the moisture content is 5.5%. In the closed reaction kettle, the temperature is slowly raised to 75 0 C, then rapidly cool down to 25 0 C and keep warm for 8 minutes; the second time slowly raise the temperature to 95 0 C, then rapidly cool down to 45 0 C and keep it warm for 8 minutes; slowly raise the temperature to 130 for the third time 0 C and keep warm; the rate of slow heating is 3 0 C / min, the rate of rapid cooling is 30 0 C / min. The reaction was stirred for 3 hours to obtain 2 o 3 6.1% (m / m), aluminum chloride liquid with a basicity of 2%, add 1.1 tons of calcium aluminate powder to the above-mentioned polyaluminum chloride liquid, the Al of the calcium pow...

Embodiment 2

[0031] Embodiment 2: the preparation method of the polyaluminum chloride of a kind of low residual aluminum of this example, its steps are:

[0032]Weigh 100 grams of hydrochloric acid with a concentration of 31%, add 26 grams of aluminum hydroxide, which contains Al 2 o 3 % is 64% (m / m), the water content is 4% (m / m), and the temperature is slowly raised to 75% in a closed reactor in a closed container. 0 C, then rapidly cool down to 25 0 C and keep warm for 8 minutes; the second time slowly raise the temperature to 95 0 C, then rapidly cool down to 45 0 C and keep it warm for 8 minutes; slowly raise the temperature to 130 for the third time 0 C and keep warm; the rate of slow heating is 3 0 C / min, the rate of rapid cooling is 30 0 C / min, stirred and reacted for 2.5 hours to obtain 2 o 3 12.6% (m / m), aluminum chloride liquid with a basicity of 10%, add 42g of calcium aluminate powder to the above polyaluminum chloride liquid, the Al of the calcium powder 2 o 3 % is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com