Automatic-directing bogie of railway truck and automatic-directing method

A technology for railway wagons and bogies, which is applied to the self-guiding method of three-piece self-guiding bogies and the field of bogies, and can solve the problem of increasing the fixed wheelbase of bogies and the center distance of axle diameters, increasing manufacturing and operating costs, and steering Increase the weight of the rack and other problems, achieve the effect of increasing manufacturing costs, facilitating installation and maintenance, and reducing manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

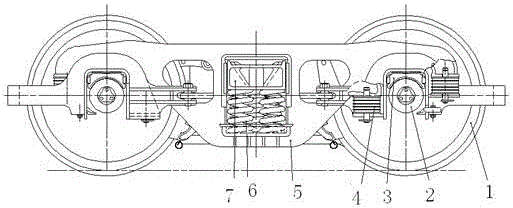

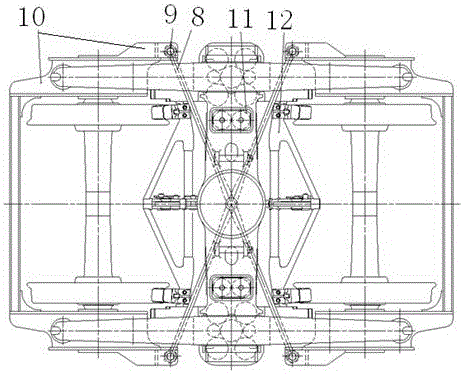

[0032] by attaching figure 1 and 2 It can be seen that the present invention relates to a self-guiding device for a railway freight car bogie, comprising: a wheel set 1, a rolling bearing device 2, a bearing saddle 3, a series of rubber springs 4, side frames 5, a central spring damping device 6, and a bolster 7. Connecting rod 8, connecting pin 9, subframe 10, side bearing 11, braking device 12, side frame 5 is pressed on the wheel pair 1 through subframe 10.

[0033] Such as figure 2 As shown, two sub-frames 10 are arranged at both ends of the bogie, the coupling pin 9 is located outside the side frame, and the connecting rod 8 passes through the holes reserved in the belly of the side frame 5 and the bolster 7 . Two sub-frames 10 and two connecting rods 8 are cross-connected through four coupling pins 9 to form a guiding device for the bogie wheel set. When the bogie passes through the curve, the guiding force applied by the rail to the wheel, through the action of the ...

Embodiment 2

[0035]The structure of the second embodiment is the same as the basic principle of the first embodiment, but the arrangement of the connecting rods is different, as shown in the attached figure 2 shown. The side frames are connected by bolsters, and the two sub-frames are connected by connecting rods, so that the left and right wheels of the vehicle are integrated to form a self-guiding device; the principle of rolling the arc-shaped barrel is used to make the wheel diameter in contact with the rail Continuously changing, thus realizing the automatic rotation rolling guide.

[0036] The two sub-frames are connected by connecting rods, and the two sub-frames are connected by bypassing the two ends of the bogie; and the connection points between the two sub-frames and the cross link are located outside the side frame (that is, away from the longitudinal centerline side of the track) ), so that when the bogie passes through the curve, the guiding force applied by the rail to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com