Rail vehicle traction system and rail vehicle

A rail vehicle and traction system technology, applied in the field of rail vehicle traction systems and rail vehicles, can solve the problems of high maintenance cost, regular maintenance, large power loss, etc., to reduce installation space and vehicle weight, reduce cost, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

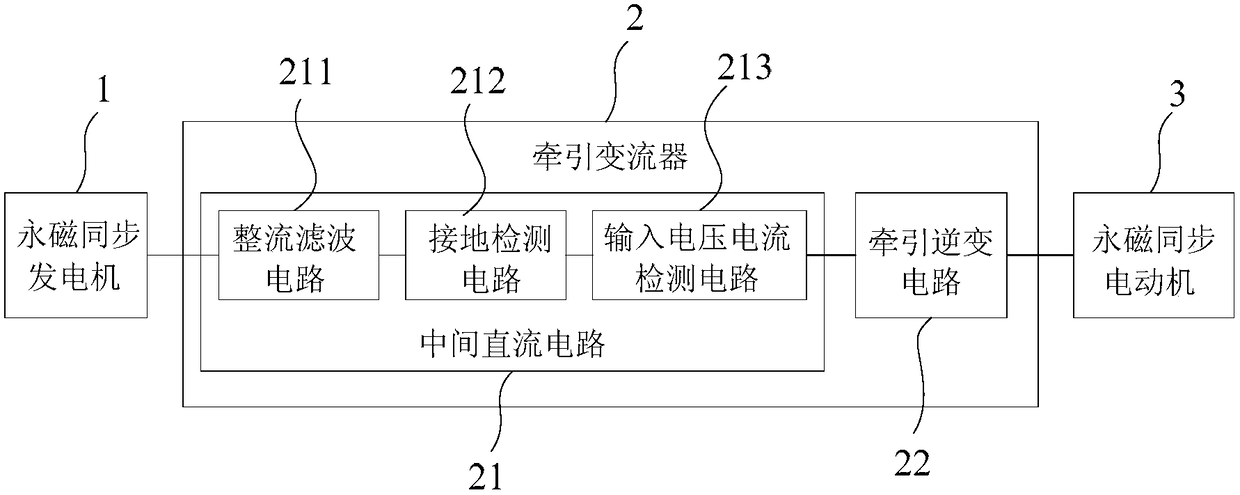

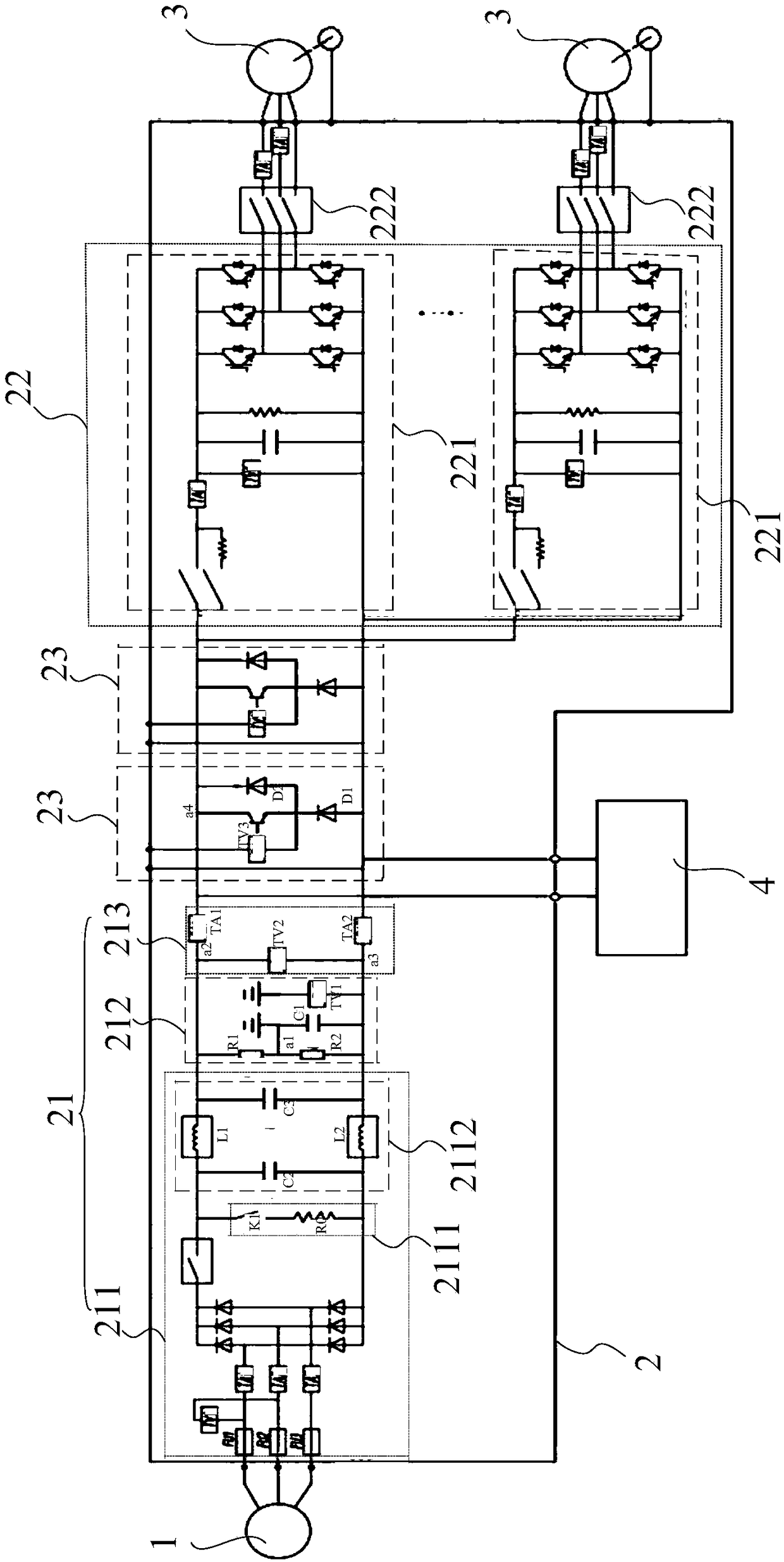

[0017] figure 1 For the structural block diagram of the rail vehicle traction system provided by Embodiment 1 of the present invention, refer to the attached figure 1 As shown, this embodiment provides a rail vehicle traction system. It should first be explained that the rail vehicles mentioned in this embodiment include but are not limited to diesel locomotives, railway vehicles, and EMUs.

[0018] The rail vehicle traction system of this embodiment includes: a permanent magnet synchronous generator 1 , a traction converter 2 and a permanent magnet synchronous motor 3 electrically connected in sequence. The permanent magnet synchronous generator 1 is mechanically connected with an external diesel engine (not shown in the figure), and is used to rotate under the drive of the diesel engine to provide three-phase AC power to the traction converter 2 .

[0019] The traction converter 2 includes: an intermediate DC circuit 21 and a traction inverter circuit 22 . Wherein, the int...

Embodiment 2

[0032] This embodiment provides a rail vehicle, including: a vehicle body, a driver's cab, and a rail vehicle traction system. Wherein, the driver's cab is located at the end of the vehicle body, and the rail vehicle traction system is installed in the vehicle body for pulling the rail vehicle.

[0033] The rail vehicle traction system in this embodiment has the same structure as the rail vehicle traction system provided in Embodiment 1, and can achieve the same technical effect, so details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com