Explosion-proof membrane production method

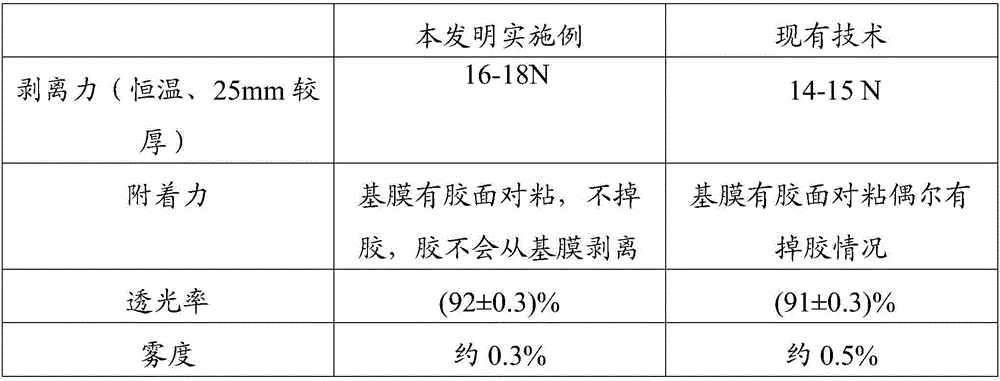

An explosion-proof film and release film technology, applied in protective equipment, chemical instruments and methods, protective clothing, etc., can solve the problems of layer-to-layer adhesion, peeling force, and overall film quality is not ideal, low light transmittance, etc. Increased life, high quality, improved adhesion and peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Explosion-proof film preparation method of the present invention, it comprises the steps:

[0027] An explosion-proof film production device is provided, including a first uncoiler, a coating machine, a composite wheel and a second uncoiler arranged in sequence, the corona machine is located between the composite wheel and the second uncoiler, and the coating machine It includes a coating roller, a glue groove and an oven, and the glue groove is connected to the coating roller through a rubber outlet pipe;

[0028] Provide the release film, put the release film on the first uncoiler, and pass the release film through the coating roller and oven of the coating machine in sequence, and then pass through the composite wheel;

[0029] Provide optical glue, add a hardener to the optical glue, wherein 1-2 mass parts of hardener are added to every 100 mass parts of the optical glue, stir and mix, control the solid content of the optical glue at 35%-45%, and mix Add the homoge...

Embodiment

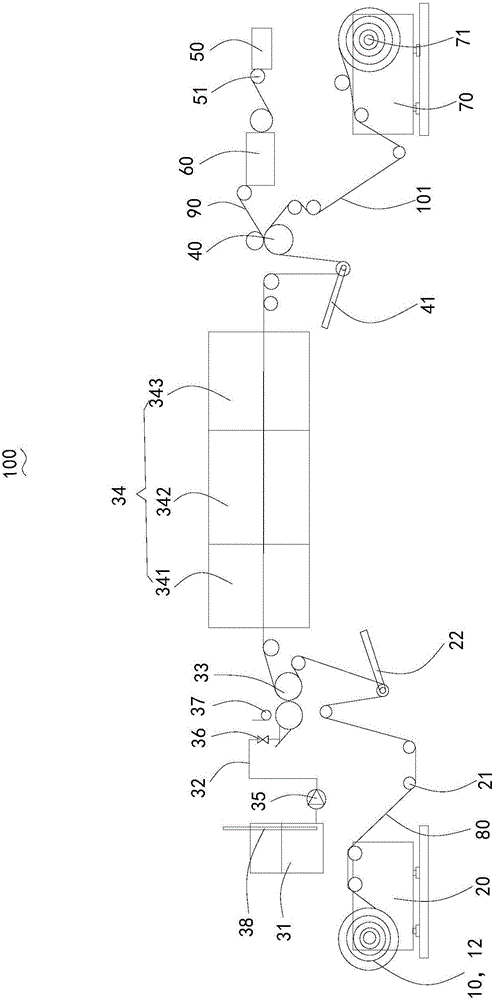

[0041] In this embodiment, the preparation method of the explosion-proof membrane provides a kind of explosion-proof membrane production device 100, referring to figure 1 , including the unwinding machine 10, the first uncoiler 20, the coating machine 30, the composite wheel 40 and the second uncoiler 50 arranged in sequence, the corona machine 60 is set between the composite wheel 40 and the second uncoiler 50, close to the compound A winder 70 is provided at the wheel 40 .

[0042] The unwinding machine 10 has an unloading wheel 12, and the release film 80 in roll form is placed on the unloading wheel 12 of the unwinding machine 10, and then unwinding can be performed.

[0043] The first uncoiler 20 includes several first feeding wheels 21 and a feeding tension control mechanism 22. There are multiple first feeding wheels 21 with different positions. The release film 80 is pulled from the feeding wheel 12 to the first feeding wheel 21. Stretching, the feeding tension contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com