Injection hook production equipment, melt filtering device thereof and manufacturing method for injection hook

A technology of filtering device and production equipment, which can be applied to other household appliances, clothing, fasteners, etc., can solve problems such as affecting the quality of injection hooks, and achieve the effect of reducing the possibility of thermal degradation, good filtering effect and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

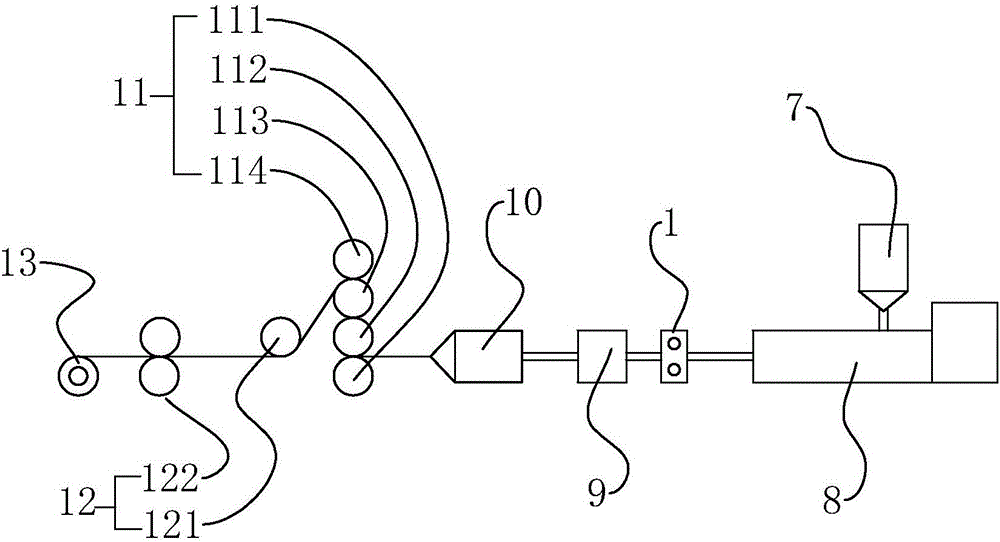

[0046] Embodiment: a kind of injection hook production equipment, such as figure 1 As shown, a drying tower 7 is included, and a discharge port is arranged below the drying tower 7. The discharge port communicates with the screw extruder 8, and the outside of the screw extruder 8 sets of barrels is wound with a group of heating coils. According to the thermocouple The temperature information fed back can control the heating temperature of each section of the sleeve. The screw extruder 8 is sequentially connected with a melt filter device 1 , a metering pump 9 , a die head 10 , a pressurizing part 11 , a guide roller 121 , a pulling roller 122 and a winding roller 13 . Wherein, the pressing part 11 includes a pressing roller 111, a mold roller 112, a peeling roller 113, and a pressing roller 114, and the four contact in sequence, and several holes arranged in the same direction and having the same shape as the injection hook are evenly provided on the mold roller 112. The die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com