Demoulding device for water filling nozzle of automobile water tank cover

A technology of automobile water tank and demoulding device, which is applied in the field of molds, can solve problems such as difficult demoulding, complex demoulding structure, and damage to the quality of injection molded parts, and achieves the effect of simple and reliable structure, precise step-by-step action, and clear action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

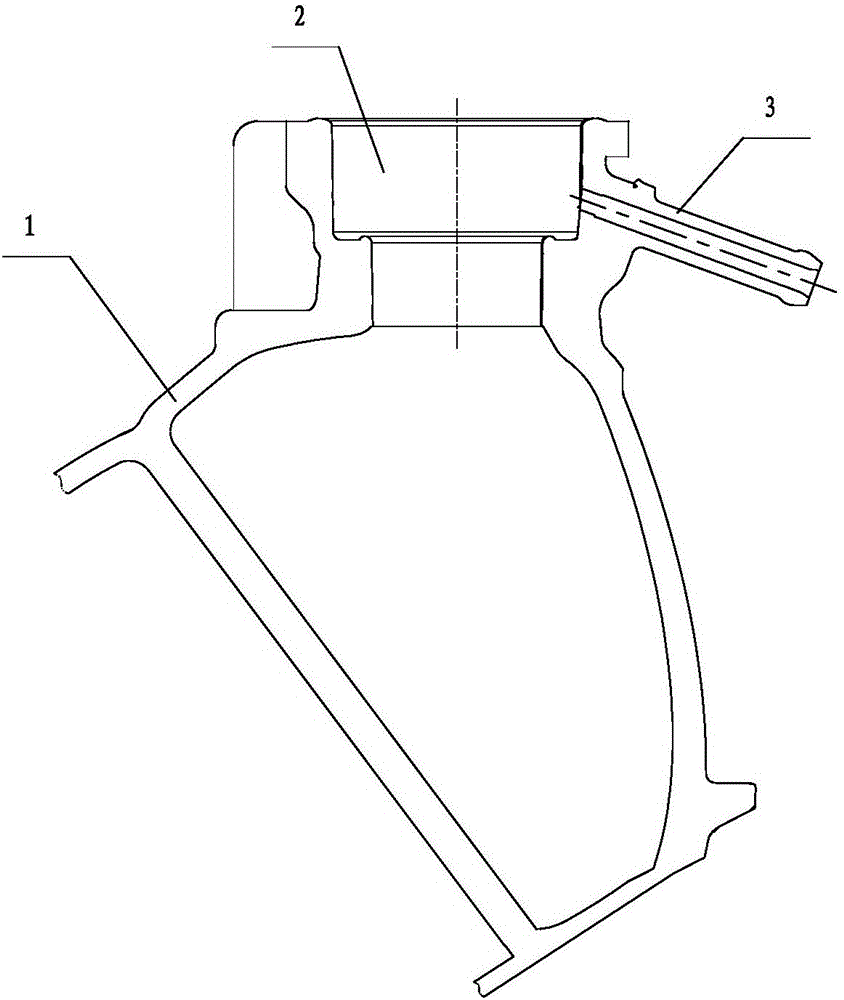

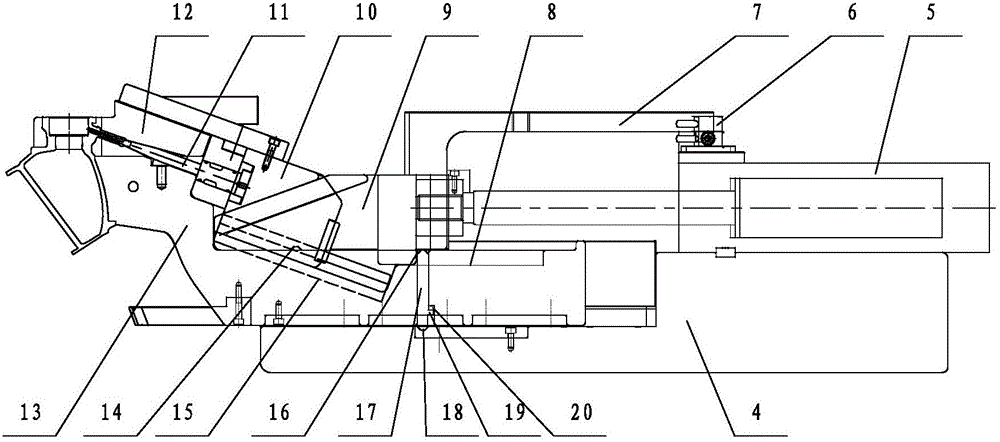

[0027] Depend on Figure 1 to Figure 7 It can be seen from the structural schematic diagram of the demoulding device at the water injection port of the automobile radiator tank cover of the present invention that it includes a slide table base 4, a first forming slide block 12 for molding at the water injection port of the tank cover with one side of the side pipe , the second molding slider 13 used for the side wall of the tank lid water injection port below the first molding slider 12, the slider insert 11 used to form the inner hole of the side pipe and the slider insert 11 for driving core pulling, The linkage driving mechanism for demolding the first forming slider 12 and demoulding the second forming slider 13 is connected to the slide base 4 . Wherein the first forming slide block 12 is two pieces, and the two first forming sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com