Core pulling device of flange mold

A core-pulling device and flange technology, applied in the field of core-pulling devices, can solve the problems of damaged products, difficult demoulding, complicated demoulding structure of hose joints, etc., and achieve the effect of clear action and reasonable steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

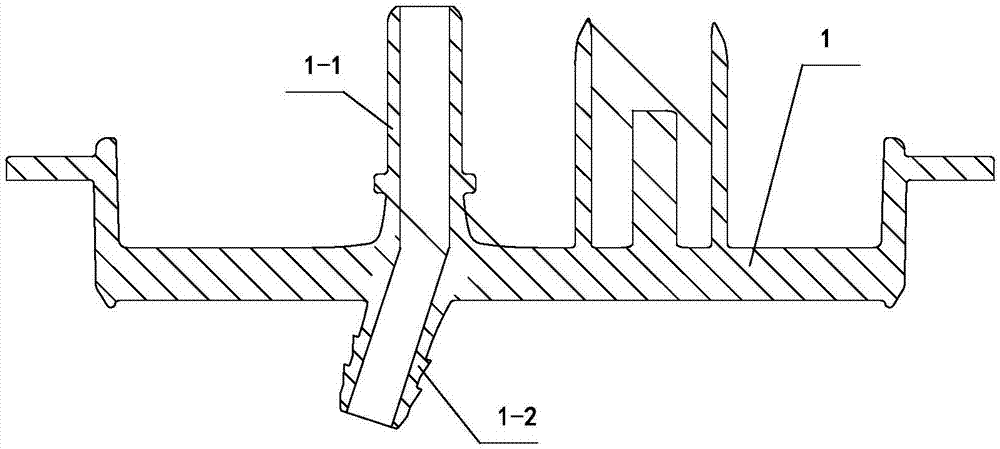

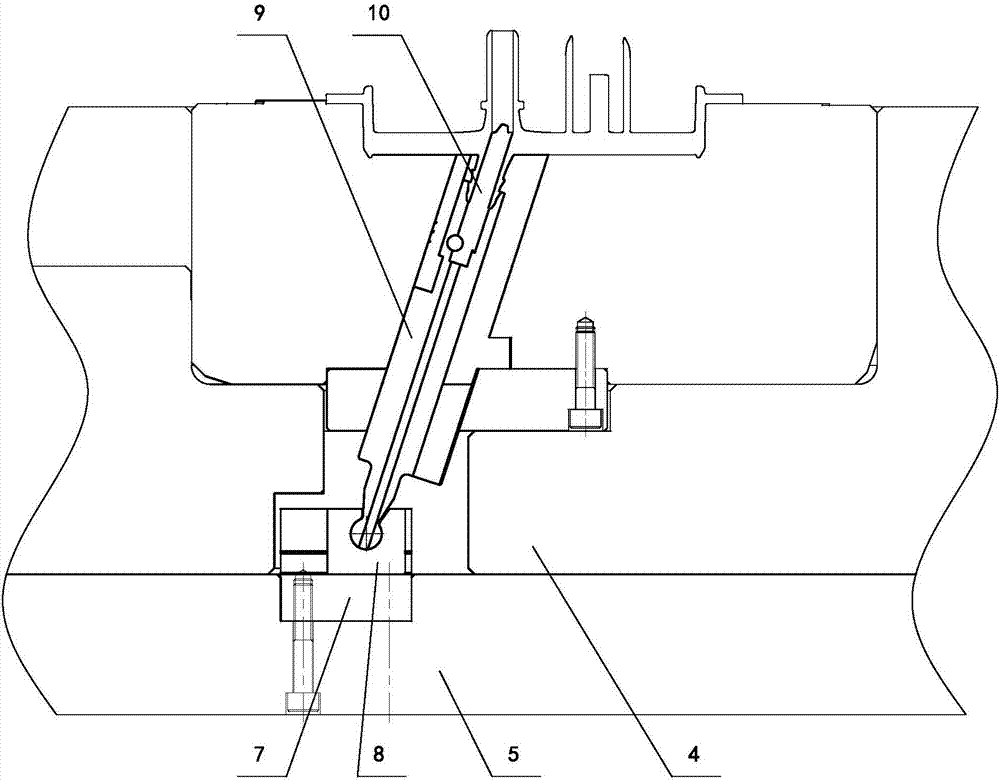

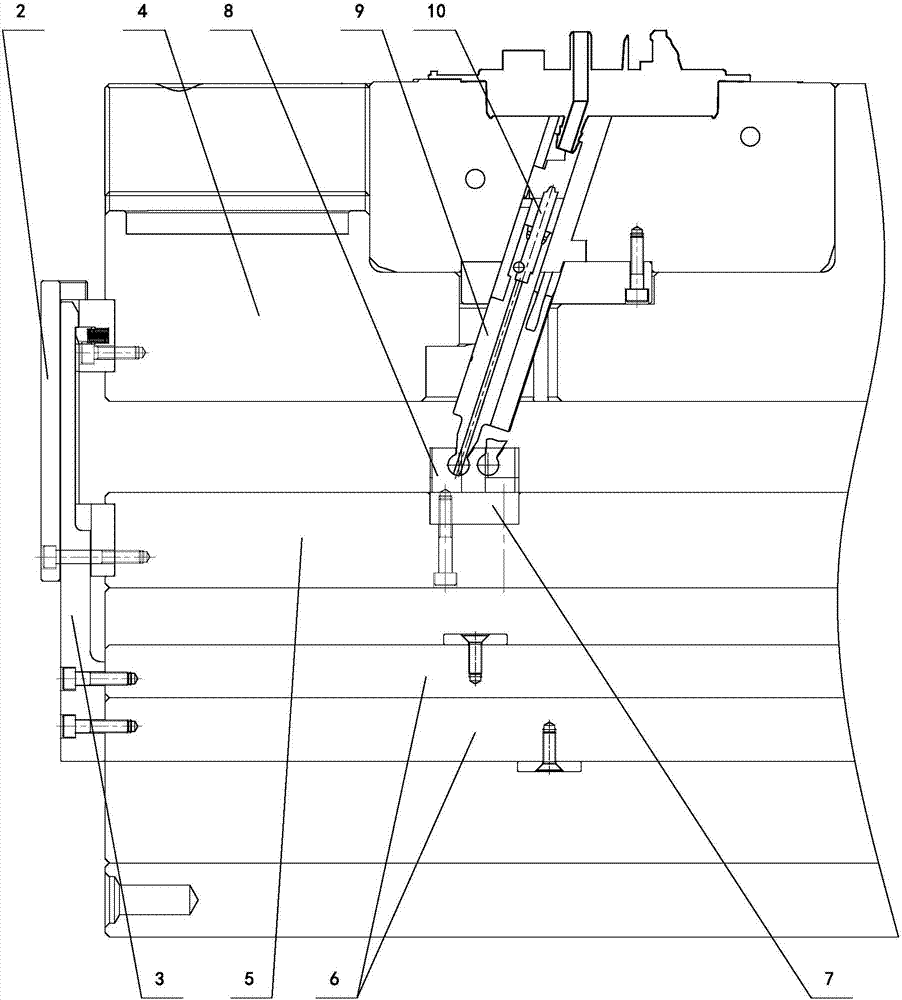

[0024] Depend on Figure 1 to Figure 8 The structure diagram of the core-pulling device of the flange mold of the present invention shown in the present invention can be seen, including the upper mold assembly, the lower mold assembly and the ejection mechanism, and the mold cavity of the flange is formed after the two molds are closed, and the ejection mechanism is connected to the lower mold assembly. In the mold assembly; the ejection mechanism is a secondary ejection mechanism, wherein the first-stage ejection is used to form the outer surface of the inclined flange hose joint 1-2, and is used to form an inclined flange. The core-pulling mechanism of the inner diameter of the hose joint 1-2, the second-stage ejector is used for the overall ejection of the finished flange, and the first-stage ejector mechanism and the second-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com