High-precision and heavy-load forking mechanism

A high-precision, transmission mechanism technology, used in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of low workpiece flow efficiency, inconvenient installation and adjustment, and difficult processing and manufacturing, and achieve convenient and labor-saving later maintenance and compact structure. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

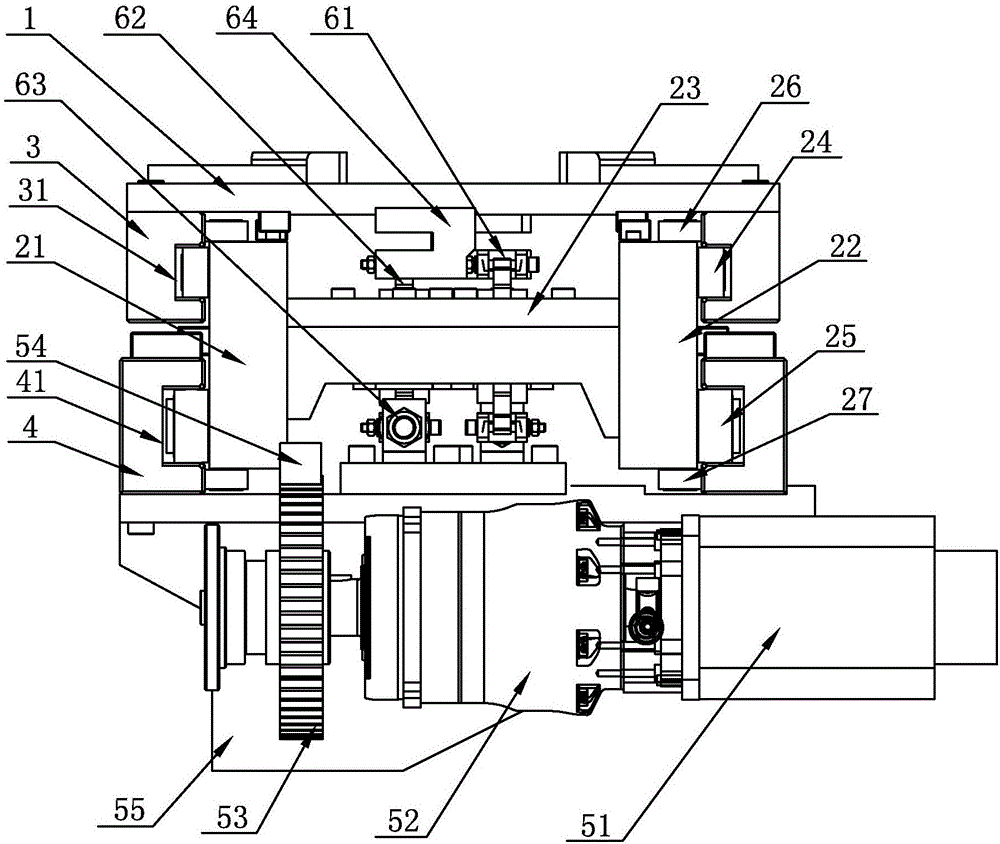

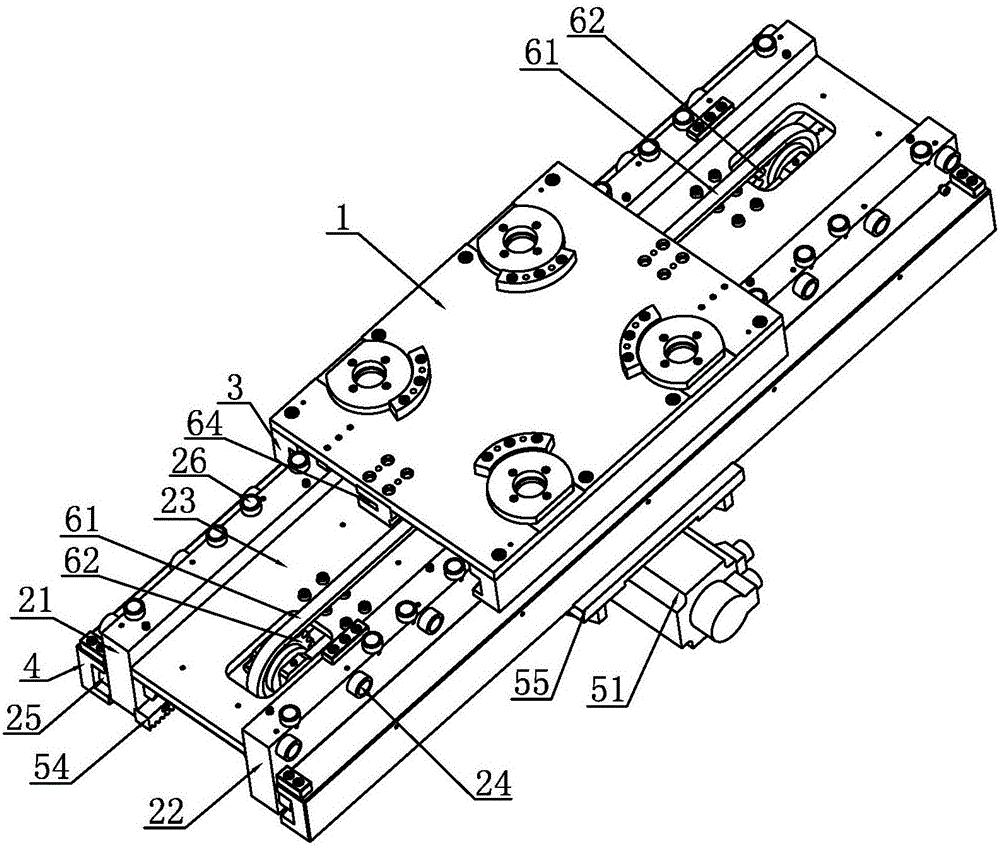

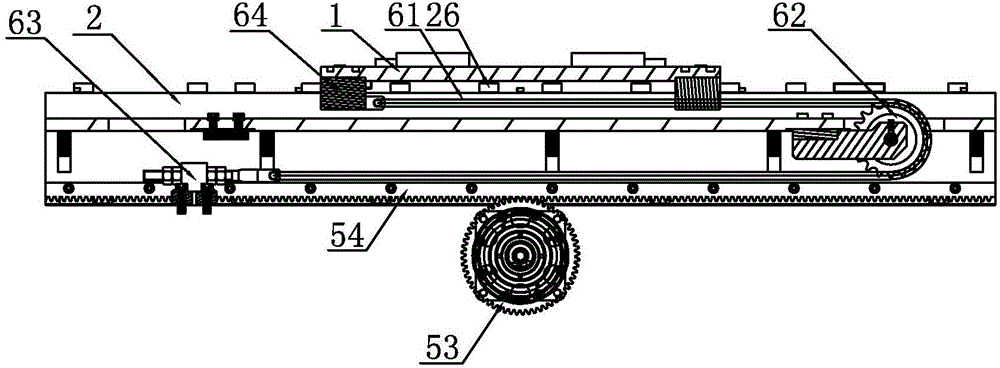

[0023]The high-precision heavy-duty forking mechanism of Embodiment 1, as shown in the figure, includes a pallet 1, a boom 2, two upper guide rails 3 and two lower guide rails 4, and the two upper guide rails 3 are rollingly connected to the two sides of the boom 2. In the upper part, two lower guide rails 4 are rollingly connected to the lower part of both sides of the boom 2, the two lower guide rails 4 are fixed on the loading platform (not shown in the figure), and the tray 1 is fixed across the two upper guide rails 3, The tray 1 is located above the boom 2, the length of the tray 1 is smaller than the length of the boom 2, and the two lower guide rails 4 are connected with the boom 2 through a first-stage transmission mechanism, which includes a servo motor 51, a deceleration Machine 52, gear 53 and rack 54, servo motor 51 is installed in a motor base 55, and motor base 55 is fixed on the bottom of two lower guide rails 4, and speed reducer 52 links to each other with the...

Embodiment 2

[0024] Embodiment 2 The high-precision heavy-duty forking mechanism, as shown in the figure, includes a pallet 1, a boom 2, two upper guide rails 3 and two lower guide rails 4, and the two upper guide rails 3 are rollingly connected to the upper parts of both sides of the boom 2 , the two lower guide rails 4 are rollingly connected to the bottom of both sides of the boom 2, and the two lower guide rails 4 are fixed on the cargo platform; the cross section of the boom 2 is H-shaped, and the boom 2 is composed of the first vertical arm 21, The second vertical arm 22 and the cross arm 23 constitute, the first vertical arm 21 and the second vertical arm 22 are arranged in parallel and are connected by the cross arm 23, and the outer sides of the first vertical arm 21 and the second vertical arm 22 are all equipped with moving parts up and down. A row of first rollers 24 and a row of second rollers 25 arranged in the length direction of the arm 2, and a row of third rollers arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com