General fixing device for laser cutting

A fixing device and laser cutting technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsuitable popularization and application, high cost, complicated device structure, etc., to improve workers' work efficiency and low cost , the effect of increasing the contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

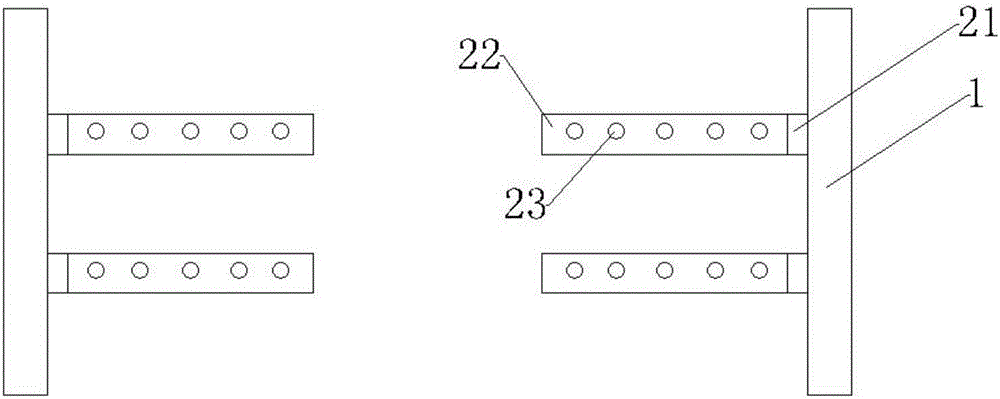

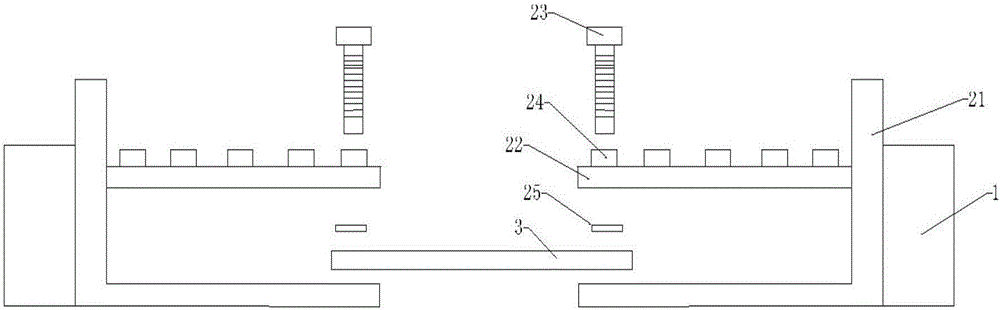

[0012] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the universal fixing device for laser cutting includes two relatively parallel guide rails 1, and slide plates are arranged on the opposite surfaces of the two guide rails 1, and the slide plates include side plates 21 connected with the guide rails, and are connected with the guide rails. The lower plate integrally connected with the side plate 21 and the upper plate 22 slidably connected with the side plate 21 are provided with fixing parts for fixing workpieces 3 of different widths. The present invention solves the problem of fixing workpieces 3 of different widths by arranging several fixing parts on the upper plate 22, and solves the problem of fixing workpieces 3 of different thicknesses by setting the upper plate 22 sliding up and down on the side plate 21. .

[0013] The fixing part is a pressing device.

[0014] The pressing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com