Double vortex volute sand core seamless combination process

A combined process and double eddy current technology, applied in cores, manufacturing tools, metal processing equipment, etc., can solve problems such as imperfect sand core processes, achieve the effects of saving labor input, convenient operation, and saving artificial secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

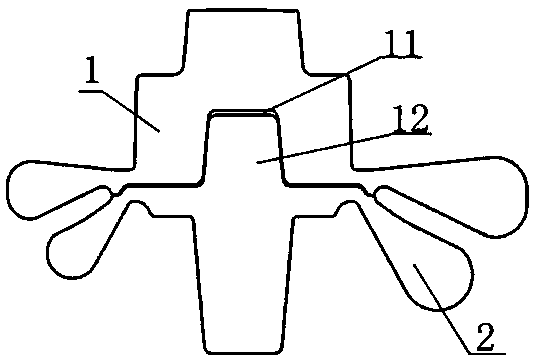

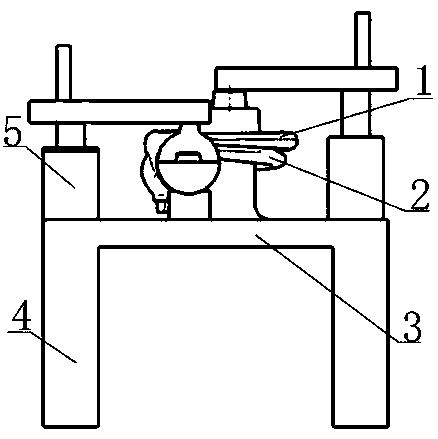

[0017] Figure 1-3 , double vortex volute sand core seamless combination process, specifically,

[0018] 1) Core making, the double vortex volute sand core is divided into upper sand core 1 and lower sand core 2, which are respectively made and shaped by sand core molds;

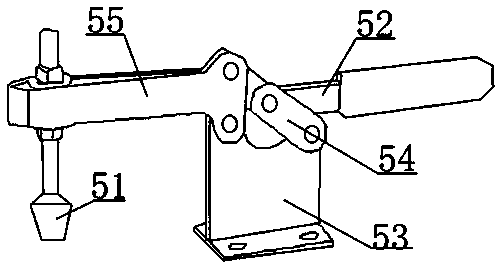

[0019] 2) Assemble the sand core, clean the sharp corners of the upper sand core 1 and the lower sand core 2 with electrodes, and apply a layer of adhesive on the joint, the upper sand core is fastened on the lower sand core, and the upper sand core The sand core and the lower sand core are connected by an adhesive, and the upper sand core and the lower sand core are placed together on the auxiliary tooling for 1-2 minutes, and the adhesive is cured to make the gap between the upper sand core and the lower sand core The gap is 0.1mm;

[0020] 3) Soak the sand cores, place the bonded sand cores in the paint mixing tank for soaking, and the Baume degree of the paint will reach 30;

[0021] 4) Drying, drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com