Online detection ultrafine pulverizing production line

An ultra-fine grinding and production line technology, applied in the field of material grinding, can solve the problems of low production efficiency, detection and production are not carried out at the same time, and achieve the effect of ensuring high-efficiency production and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

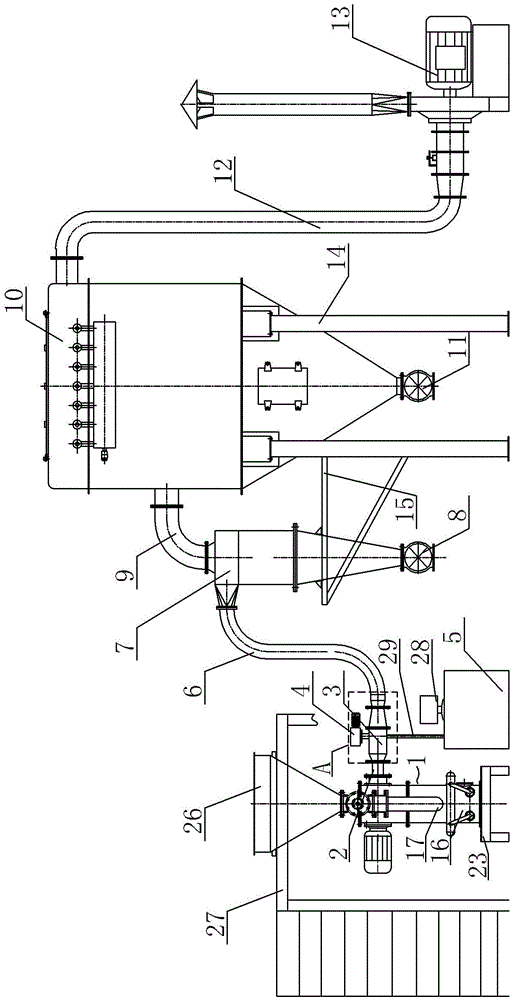

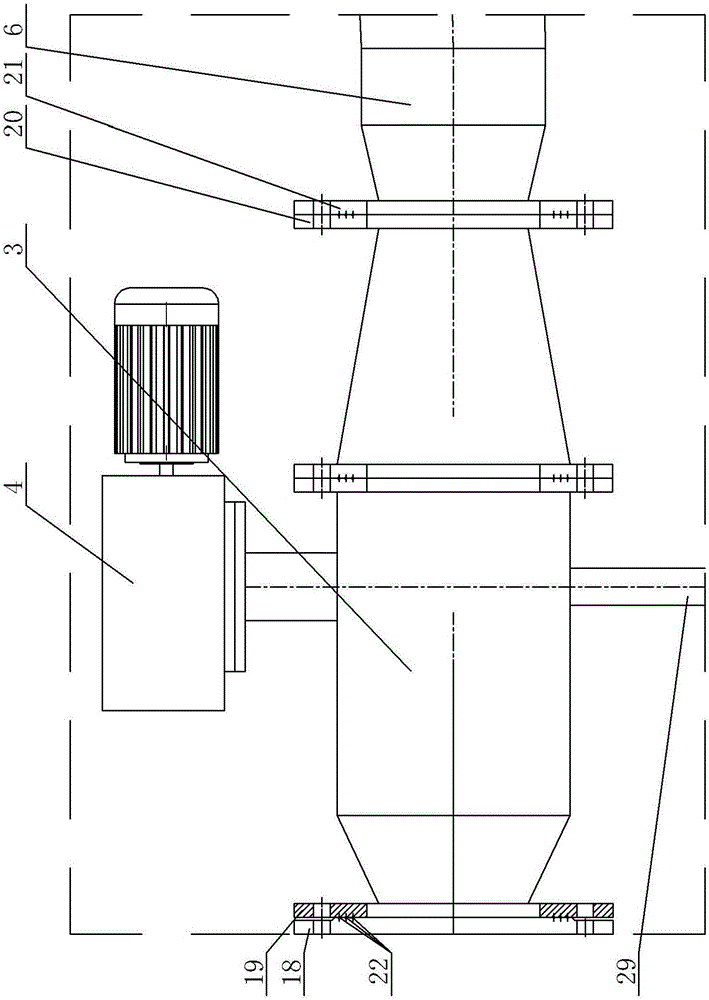

[0028] Specific embodiment one, see figure 1 The material inlet 17 is located at the middle outer ring surface position of the crushing chamber 16, the discharge port 2 is located at the upper outer ring surface position of the crushing chamber 16, and the outlet end of the discharge port 2 passes through the first connecting flange 18, the second The connecting flange 19 is connected to the detection chamber 3 , the crushing chamber 16 is supported on the bottom bracket 23 , the feed port 17 is connected to the discharge port of the feed bin 26 , and the feed bin 26 is arranged on a steel platform 27 .

specific Embodiment 2

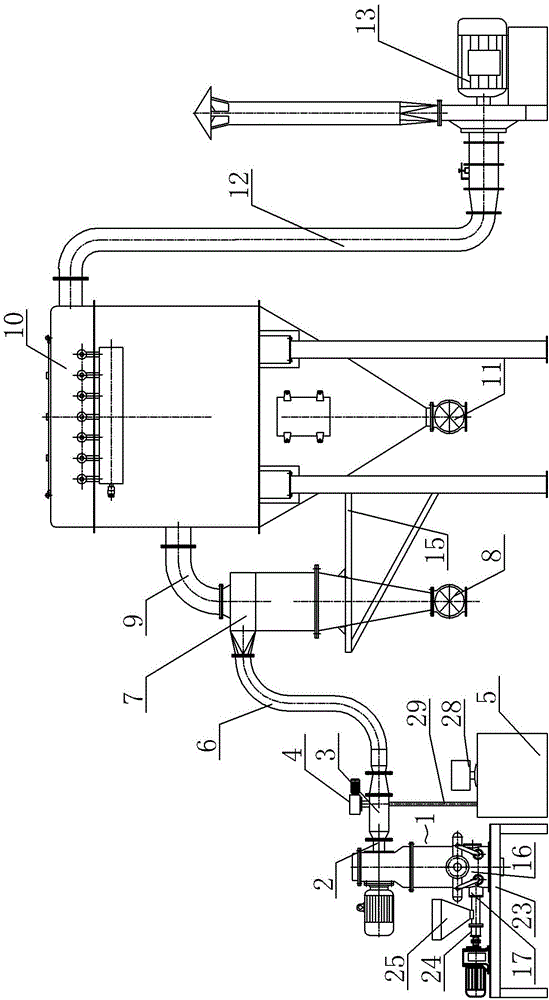

[0029] Specific embodiment two, see figure 2 The feeding port 17 is located at the bottom side of the crushing chamber 16, the feeding port 17 is externally connected with a screw feeder 24, the feeding position of the screw feeding machine 24 is provided with a hopper 25, and the discharge port is located at the upper end of the crushing chamber 16 On one side, the outlet end of the discharge port 2 is connected to the detection chamber 3 through the first connecting flange 18 and the second connecting flange 19 , and the crushing chamber 16 is supported on the bottom bracket 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com