Feeding mixing equipment

A mixing equipment and material mixing technology, which is applied in the field of material transmission, can solve the problems of scattered movement paths, difficult control, material particle breakage, etc., and achieve the effect of firm filtering control part, difficult cleaning and simplified overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

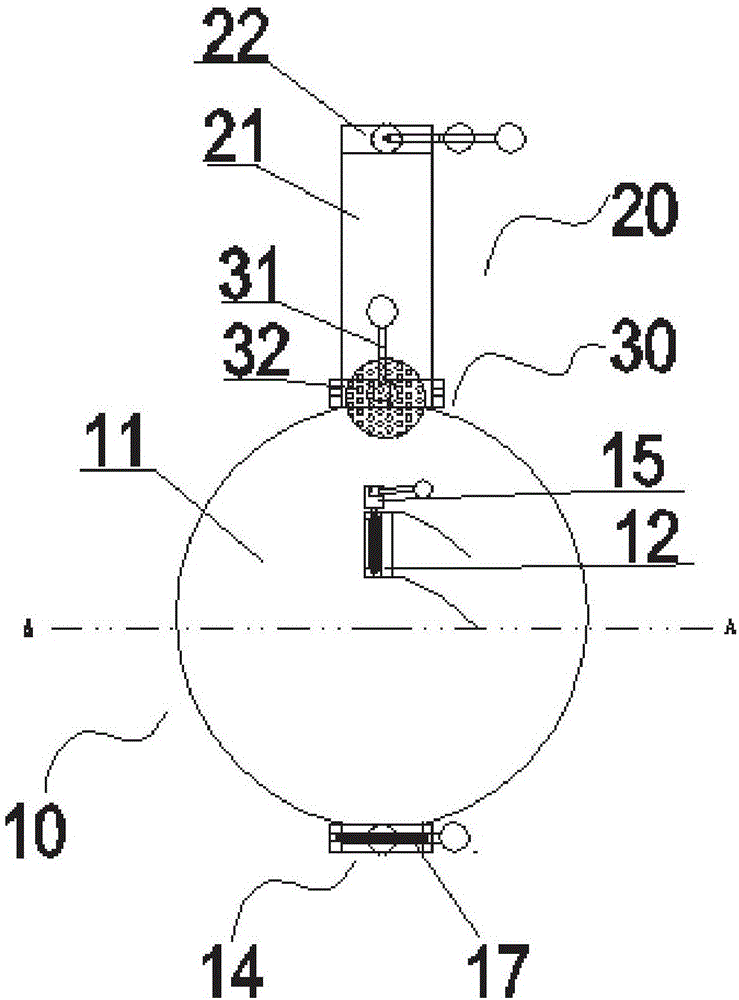

[0027] Example: such as figure 1 As shown, this embodiment provides a specific embodiment of a feeding and mixing equipment, which is suitable for the transmission of materials and the mixing of materials, which adopts a vacuum suction process, and is suitable for -0.1Mpa vacuum suction All materials can be applied, and the materials can be solid or liquid, and the scope of application is wide.

[0028] The feeding and mixing equipment in this embodiment includes a material mixing device 10 and a gas control device 20 connected to the material mixing device 10. In a vacuum state, the feeding and mixing equipment sucks materials into the material mixing device 10 for material transfer or mixing. .

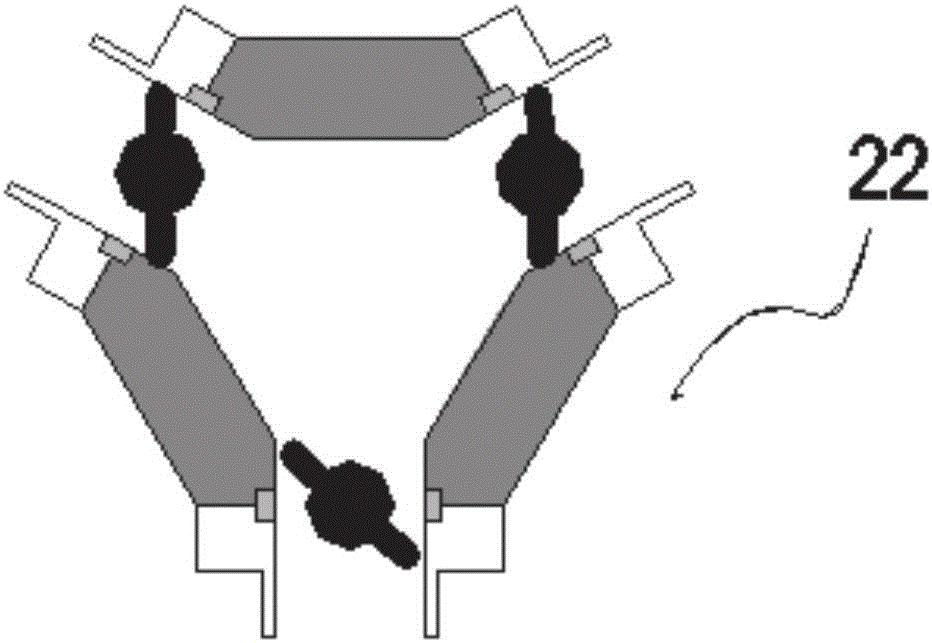

[0029] The gas control device 20 includes a filter control part 30 arranged between it and the material mixing device 10, and a buffer chamber 21 also arranged between the gas control device 20 and the material mixing device 10, and the buffer chamber 21 is used to accommodate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com