A kind of dissolvable hollow microneedle and preparation method thereof

A soluble and microneedle technology, applied in the field of microneedles, can solve the problems of non-closed hollow structures, etc., and achieve the effects of prolonging the shelf life, simple preparation method, and increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolvable hollow microneedles are prepared by the following method, the steps are:

[0042] 1. Prepare hyaluronic acid sodium salt solution: accurately weigh 80-200mg of hyaluronic acid sodium salt into a 1.5mL centrifuge tube, add 1mL dH 2 O, put it on a rotary mixer and mix it upside down for 3-7 days to mix the sodium hyaluronate evenly and use it as a high-concentration sodium hyaluronate solution for later use; at the same time, accurately weigh 50-150 mg of sodium hyaluronate into a 1.5 mL centrifuge In the tube, add 1mLdH 2 O, mix according to the above method, and use it as a low-concentration sodium hyaluronate solution for subsequent use;

[0043] 2. Take 50uL of the above-mentioned high-concentration sodium hyaluronate solution into a microneedle polydimethylsiloxane (PDMS) mold, the mold size is 1cm×1.3cm, the height of the microneedle is 50-1000μm, 4°C 1500rpm Centrifuge horizontally for 10 minutes; take out the mold and rotate it at 180 degrees and pla...

Embodiment 2

[0048] The dissolvable hollow microneedles filled with powdered medicaments are prepared by the following method, the steps are:

[0049] 1. Prepare a microneedle array with a hollow structure according to the method described in steps 1-3 in Example 1;

[0050] 2. Pour 1-2 mg of powdered medicine into the prepared hollow microneedles, centrifuge horizontally at 3000 rpm at 4°C for 10 minutes, take out the mold and rotate it 180 degrees, and continue to centrifuge for 10 minutes. Repeat this centrifugation for 3 times to make the powdered medicine enter the microneedle For the hollow part of the needle, wipe off the excess powder on the surface with a cotton swab;

[0051] 3. Add 30 μL of 5-15% (w / v) sodium hyaluronate solution on the surface of the mold, and centrifuge horizontally at 3000 rpm at 4°C for 10 minutes; take out the mold and rotate it 180 degrees, and continue to centrifuge horizontally at 3000 rpm at 4°C for 10 minutes; then take out the mold , placed in a desi...

Embodiment 3

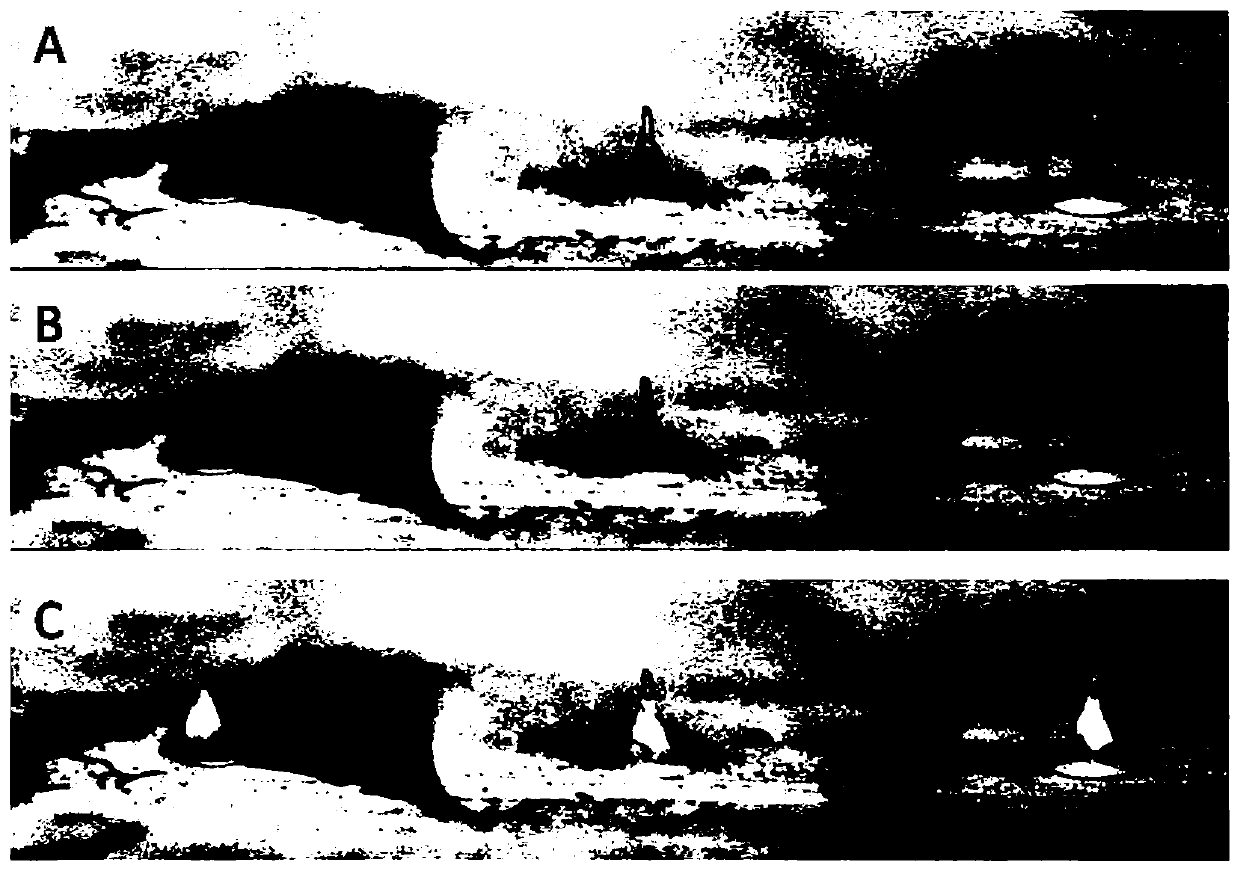

[0054] Microneedle structure detection, detection methods and results are as follows:

[0055] 1. Slice to observe the hollow structure of the microneedle

[0056] Weigh 5 μg sulforhodamine B (SRB), add to 1mL dHO 2 In O, the sodium hyaluronate solution dyed by SRB was prepared according to the method described in step 1 of Example 1, and then the hollow microneedle patch of SRB dyed was prepared according to the method described in Example 1; the microneedle patch of SRB dyed was placed vertically Put it into liquid paraffin, and cool it quickly, then fix it on a microtome and slice it every 20 μm, and observe the microneedle structure under a microscope at any time.

[0057] Such as figure 2 As shown, after the microneedle is cut, the hollow structure can be clearly seen.

[0058] 2. Observation of hollow and powder-filled microneedles under a confocal microscope

[0059] Weigh 2 μg of fluorescein isothiocyanate (FITC), add to 1mL dHO 2 O, prepare the high-concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com