Preparation method for forming ceramic dental crown/bridge through digital plane projection

A ceramic tooth and projection technology, applied in dentistry, dental prosthesis, medical science and other directions, can solve the problems of limited molding accuracy and forming efficiency, high material cost, sample cracking, etc. The effect of quality improvement and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

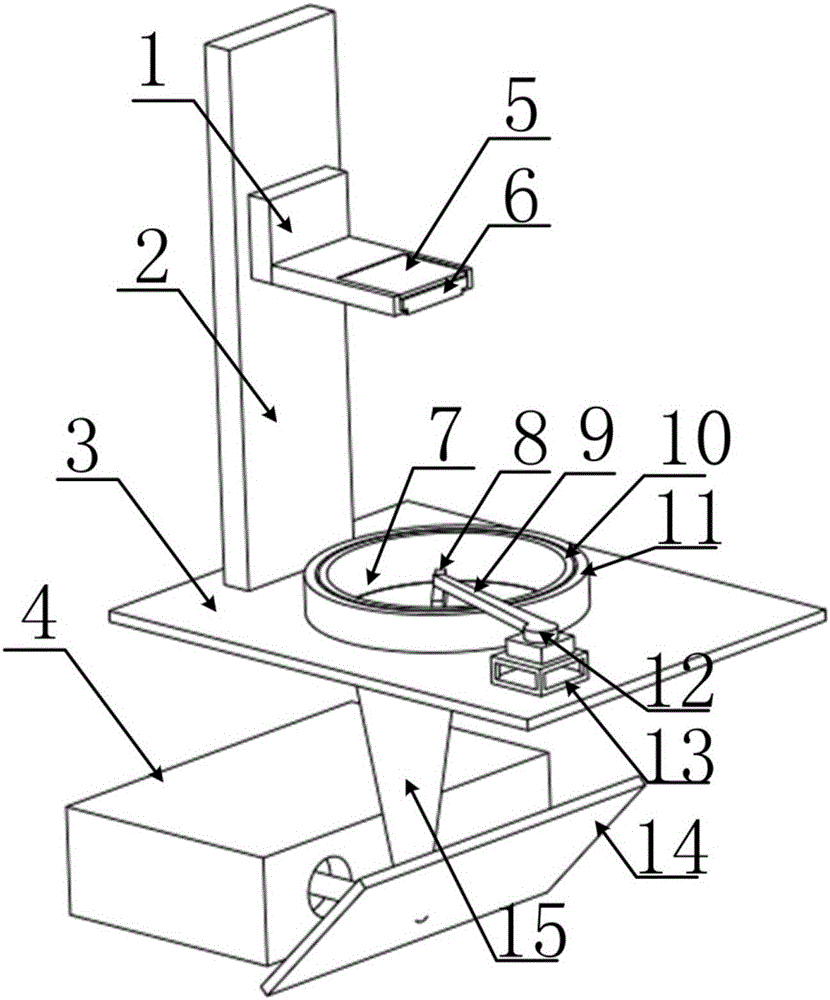

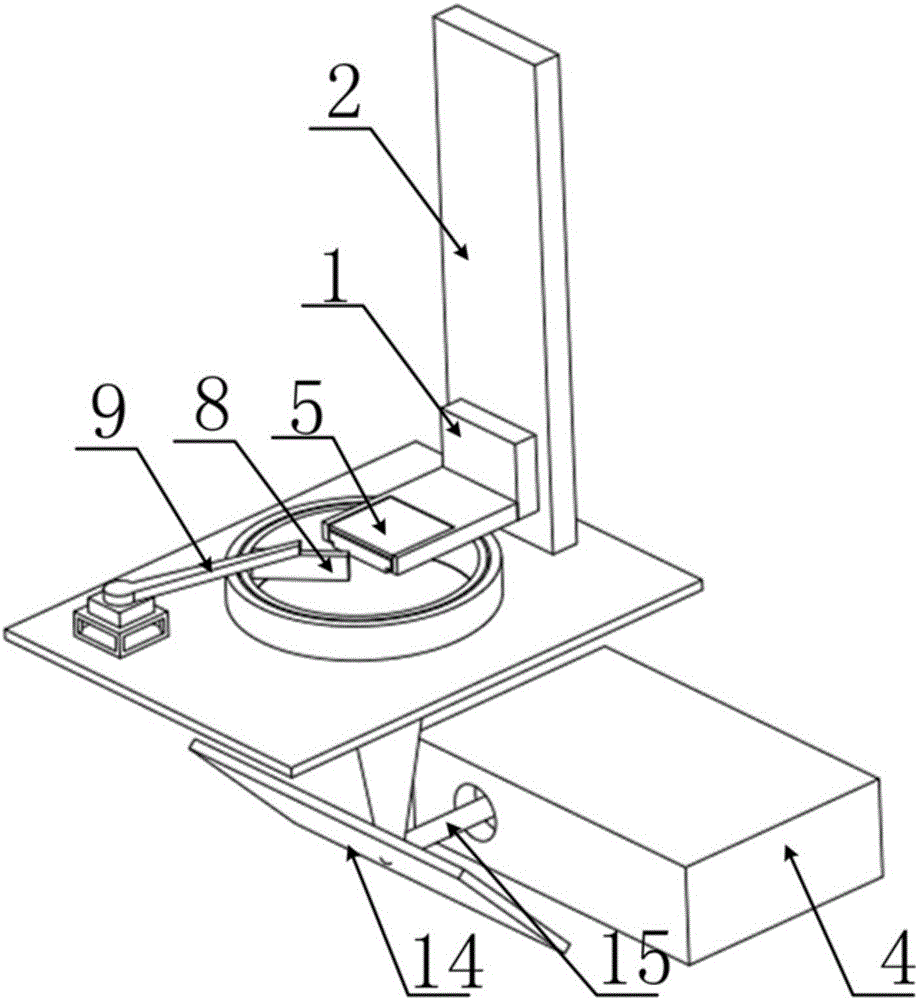

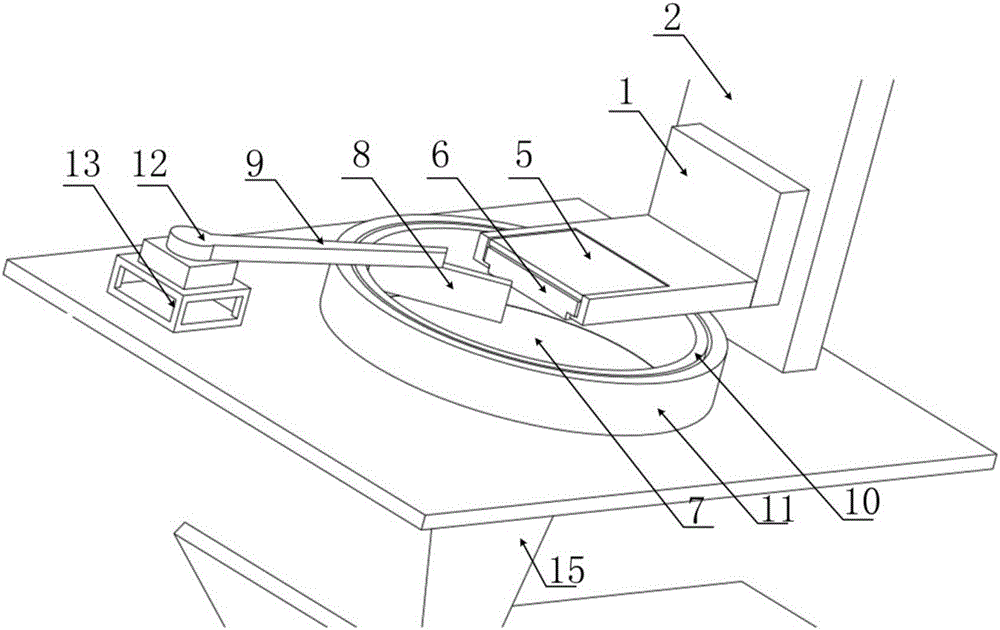

[0031] Such as Figures 1 to 4 shown. The invention discloses a method for preparing a digital surface projection forming ceramic dental crown bridge. The method is realized by a digital surface projection 3D forming device of a high-viscosity photosensitive mixed material. The device includes a control system, a workbench, and a forming mechanism placed on the workbench , a slurry box for containing photosensitive material ceramic slurry placed on the workbench and a digital projection ultraviolet light source device placed under the workbench; the movement of the molding mechanism and the operation instructions of the digital projection ultraviolet light source device are controlled by system control;

[0032] The cross-sectional shape of the slurry box is a circular structure, and it includes a slurry box outer layer cylinder 11 and a rotating slurry box inner layer cylinder 10 placed therein, and the rotating slurry box inner layer cylinder 10 is driven by a motor. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com