Method for garbage low-nitrogen and low-dioxin grate incineration and device of method for garbage low-nitrogen and low-dioxin grate incineration

A technology of incineration device and garbage, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problem of difficult to control the residence time of flue gas temperature, and achieves the goal of avoiding a large amount of NOx generation, wide application prospect, and simple and easy technical means. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

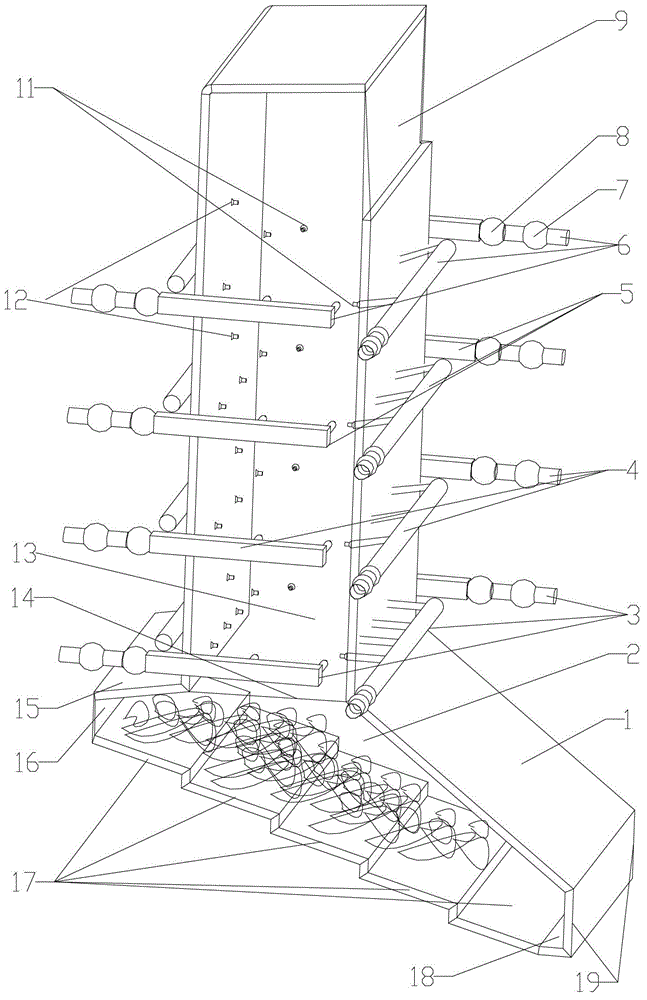

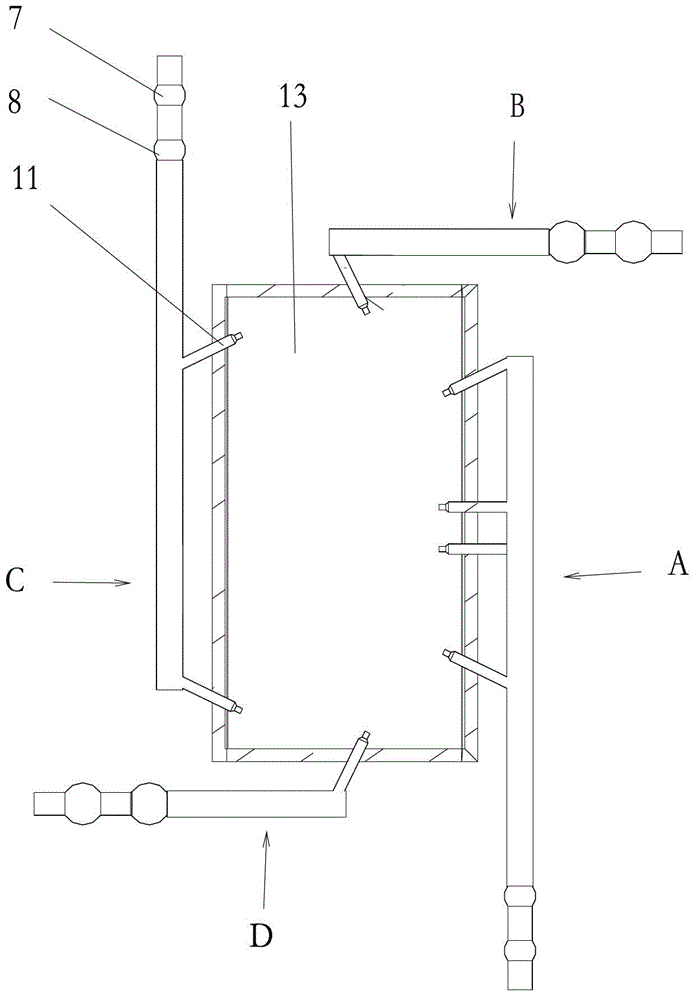

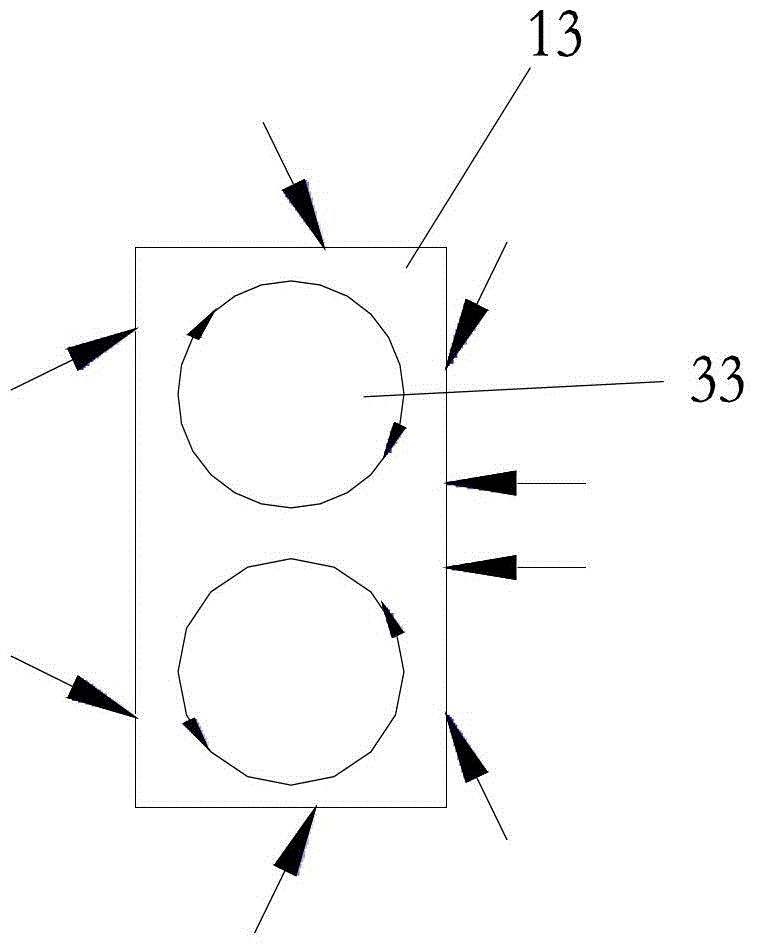

[0025] Such as figure 1 , image 3 , Figure 4 shown. Garbage low-nitrogen and low-dioxin fire grate incineration device of the present invention comprises first passage 13 and the incineration hearth 2 that is arranged on the bottom of first passage 13, is provided with along the wall around first passage 13 so that in the first passage 13 The flue gas 33 forms two groups of blowing components that cut circles and spiral upward.

[0026] Such as figure 1 , figure 2 shown. The blowing assembly is divided into four layers, which are the secondary air assembly 3, the tertiary air assembly 4, the fourth air assembly 5, and the fifth air assembly 6 from bottom to top; Wall duct assembly A, left wall duct assembly B, front wall duct assembly C, and right wall duct assembly D. The spacing between these four layers of blowing components is 1 / 5 of the height of the first channel 13 . The distance between the secondary air assembly 3 and the outlet 14 of the incinerator is bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com