Binding technology of bra mold cup and binding structure and binding tape thereof

A technology of wrapping tape and mold cup, applied in bras, clothing, bras, etc., can solve the problems of easy piercing of small burrs or hard wires, itching of the wrapping tape, etc., to solve itchy skin, improve comfort, and improve the Adhesion and Barrier Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

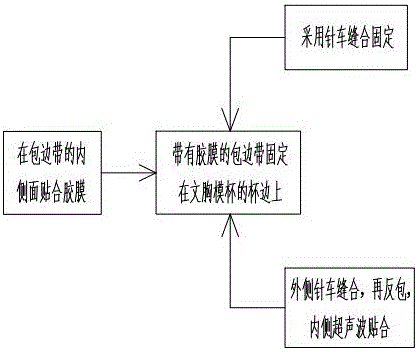

[0026] like figure 2 Shown, the hemming process of bra mold cup of the present invention mainly is to carry out in the following manner:

[0027] Step 1: First, a barrier layer 2 is provided on the inner side of the edging tape 1 .

[0028] In this embodiment, the barrier layer is an adhesive film, the adhesive film is an ultra-thin adhesive film, and the thickness of the ultra-thin adhesive film is 0.01-0.5 mm. The adhesive film may be an elastic or inelastic adhesive film. The adhesive film is hot-bonded or pasted on the inner side of the edge-wrapping tape. The width of the edging tape is 0.6cm~3.0cm. The edging may be elastic or non-elastic.

[0029] The width of the adhesive film is slightly smaller than the width of the edging tape, and the specific size can be selected according to actual needs and order requirements. Generally, the width of the adhesive film is 1 / 3-1 / 5 smaller than the width of the edging tape. Of course, the width of the adhesive film can also ...

Embodiment 2

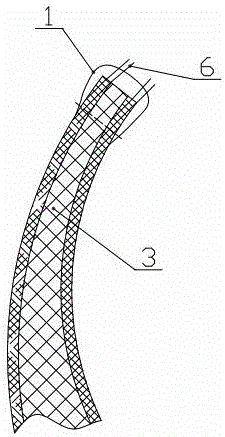

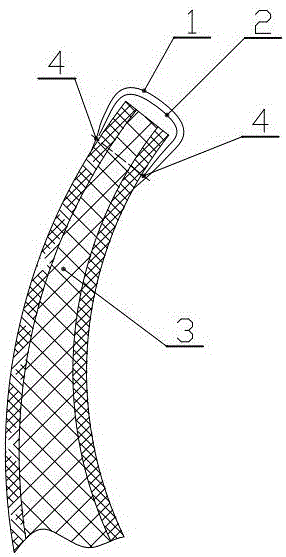

[0035] like image 3 and Figure 4 As shown, the bra mold cup hemming structure of the present invention, this hemming structure is the hemming structure that adopts above-mentioned hemming process to form, it is characterized in that, this hemming structure comprises the hemming belt that is fixed on the cup edge of bra mold cup 1. A barrier layer 2 is provided on the inner side of the edge-wrapping tape 1 .

[0036] In this embodiment, the barrier layer is an adhesive film, and the adhesive film 2 is an ultra-thin adhesive film. The thickness of the ultra-thin adhesive film is 0.01-0.5 mm. The adhesive film may be an elastic or inelastic adhesive film. The adhesive film is hot-bonded or pasted on the inner side of the edge-wrapping tape. The width of the edging tape is 0.6cm~3.0cm. The edging may be elastic or non-elastic.

[0037] In this embodiment, the width of the adhesive film 2 is slightly smaller than the width of the edging tape, and the specific size can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com