Visual combustion chamber capable of flexibly adjusting flow-pressure wave-combustion interaction

A pressure wave and combustion chamber technology, applied in the field of optical test equipment, can solve the problems of no air intake system, difficult to carry out flow-to-combustion research, etc., and achieve the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

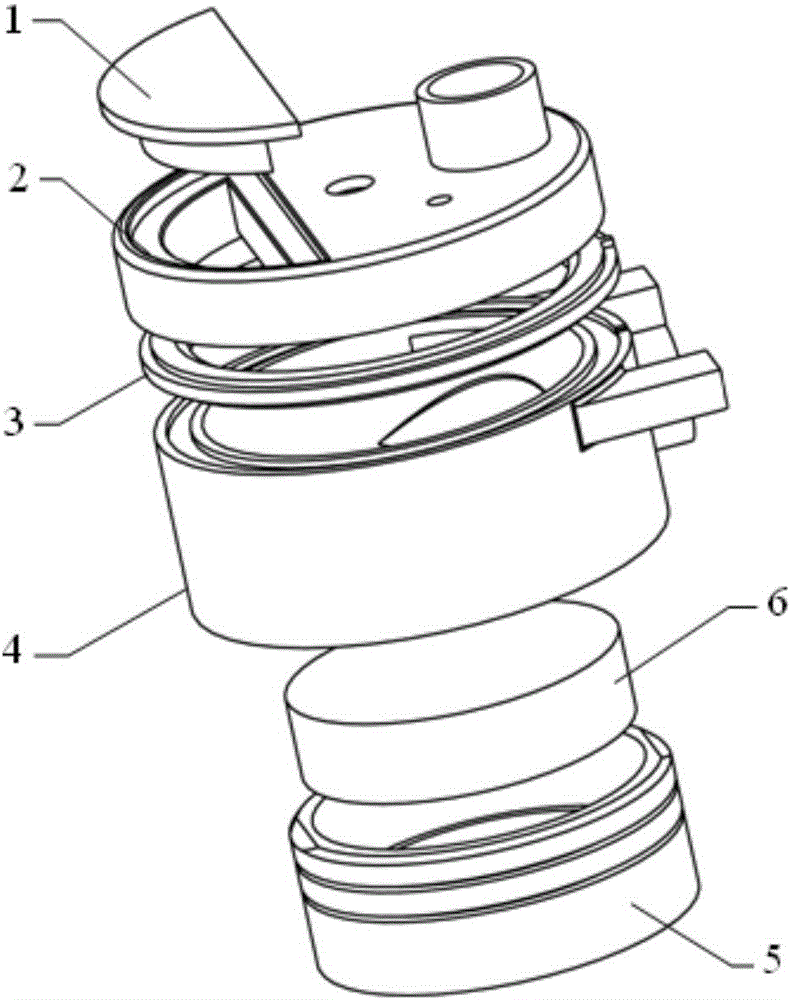

[0030] The way in which the visualization combustion chamber of the present invention is installed in the experimental system using laser testing means is as follows: Figure 4 As shown, the cylinder liner 4 is installed above the base 16 , and the transparent glass gasket 3 is placed between the cylinder head 2 and the cylinder liner 4 . A high-speed camera 12 is installed vertically above the glass window 1 of the cylinder head, and its light path for taking pictures just passes through the glass window 1 of the cylinder head for observing the spontaneous combustion process of unburned gas at the end of the combustion chamber. A horizontal plate 15 is fixed on the base 16, a 45 ° reflector 14 is installed on the horizontal plate 15, and a high-speed camera 12 is installed horizontally, and its photographing optical path just passes through the 45 ° reflective mirror 14 and the piston glass window in turn 6. Used to observe spark plug ignition and flame propagation process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com