Recovery of intermittent lost heat

A rotary kiln and facility technology, applied in the field of intermittent heat loss recovery, can solve the problems of increasing equipment heat consumption and not being able to fully optimize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

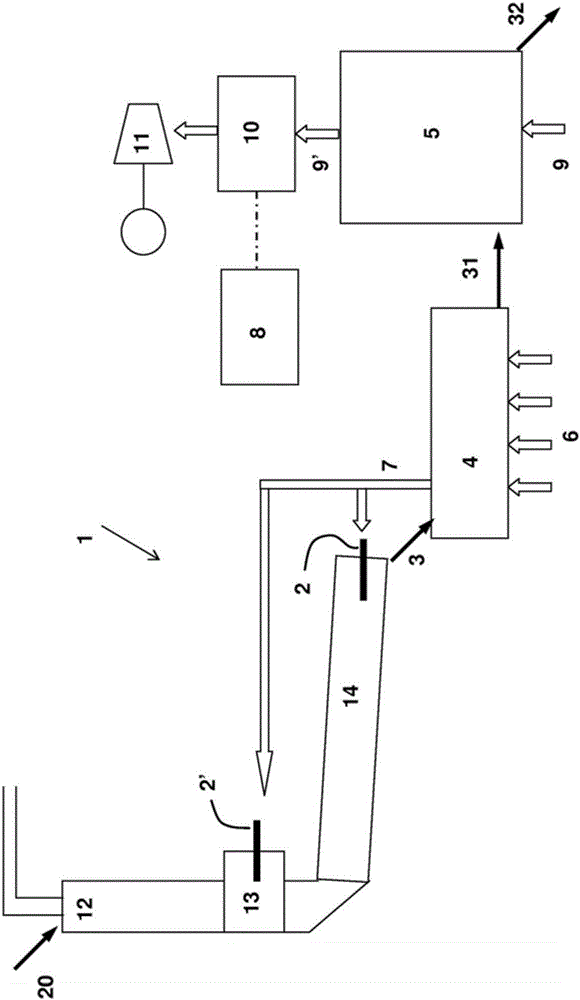

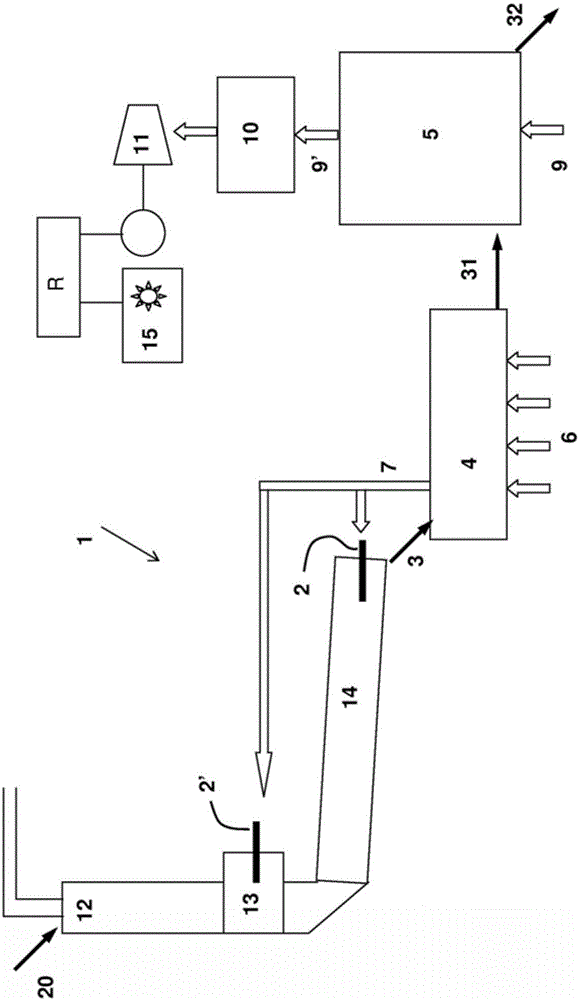

[0045] The invention firstly relates to a process for the production of cement clinker carried out in a continuous production plant 1 with at least one fuel combustion zone 2, 2' for the combustion of inorganic raw materials, wherein the raw materials are converted into clinker by combustion to obtain heat The clinker 3 is then cooled in two consecutive steps, the first cooling step being carried out in the first cooler 4 and the second cooling step being carried out in the second cooler 5 .

[0046] In conventional manner, the continuous production facility may comprise a cyclone preheater 12 , possibly a calciner 13 equipped with one or more burners 2 ′, and a rotary kiln 14 equipped with one or more burners 2 . The hot gas outlet of the calciner 13 can be supplied to the bottom of the cyclone preheater 12 . The hot gas outlet of the rotary kiln 14 may feed the cyclone preheater 12 .

[0047] In this facility, the raw material 20 is preheated in a cyclone preheater 12 , it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com