Insulation puncturing terminal structure for wire connector

A technology of insulation puncture and terminal structure, applied in the direction of connection, fixed connection, conductive connection, etc., can solve the constraints of the development of intensification and miniaturization of electrical products, occupy a lot of space, and cannot meet high-density small space cable connections, etc. problem, to achieve the effect of simple structure, small connection space and high cable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

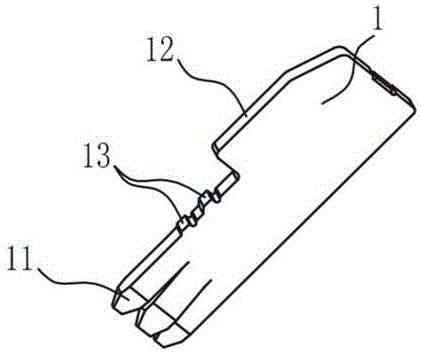

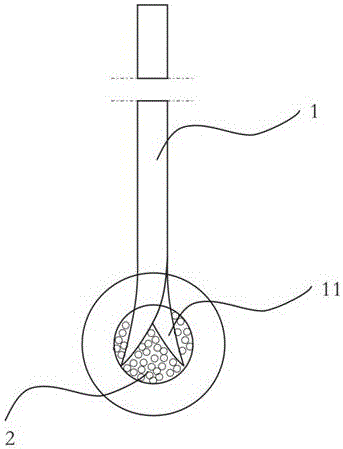

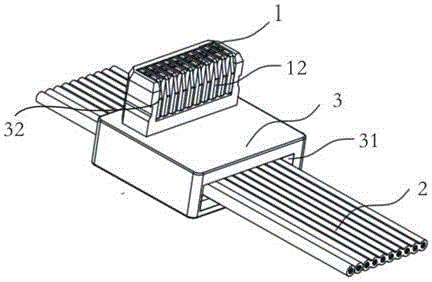

[0012] refer to figure 1 , figure 2 , image 3 , the present invention includes a flat terminal 1, a cable 2 and a base 3, wherein the flat terminal 1 is flat, one end of the flat terminal 1 is provided with a spike 11, the other end is provided with a contact area 12, and one side is provided with several inverted The thorns 13, the thorns 11 are divided into a plurality of thorns to form a comb shape, and the thorns 11 are arranged alternately and inclined along the plate, that is, the thorns 11 are upturned or downturned along the plate;

[0013] The base 3 is composed of a vertically arranged terminal cavity 31 and a horizontally arranged cable cavity 32; the flat terminal 1 is a plurality of pieces, which are inserted side by side into the terminal cavity 31 of the base 3, and the cable 2 is arranged on In the cable cavity 32 of the base 3 , the spike 11 of the flat terminal 1 pierces the insulating layer of the cable 2 and conducts with the cable 2 .

[0014] Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com