Automatic iron core turnover device and turnover method thereof

An automatic flipping and flipping device technology, which is applied in the manufacture of magnetic cores, inductors/transformers/magnets, electrical components, etc., can solve the problems of easily damaged amorphous alloys, heavy amorphous alloy iron cores, and low operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

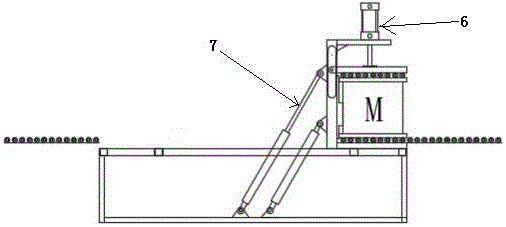

[0039] The drawings non-limitingly disclose the specific structure of the device of the present invention and its specific work realization process.

[0040] Such as figure 1 As shown, the structure of the present invention is: an automatic iron core turning device, which includes a bracket (1) connected to the adsorption unit (4), the receiving unit (2), and the feeding unit (1) on the frame (1) 5) The clamping unit (6), the turning unit (7) and the indicating iron core unit M, as well as the control unit used to control the above-mentioned units; the receiving unit (2) is used to receive the iron conveyed from the upstream conveying equipment The core unit M; the adsorption unit (4) is used to supply and remove the upper and lower wood blocks (3, 3') on the top surface of the core unit M; the turning unit (7) is used to be able to be in the original position relative to the frame Turn 180° between the turning position and the turning position; the feeding unit (5) is used to tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com